Automatic white wine blending system based on odour control

A technology of odor control and liquor, applied in the field of blending system, can solve the problems of affecting the quality and consistency of finished products, differences in flavor of finished products, and low success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and concrete example further illustrate:

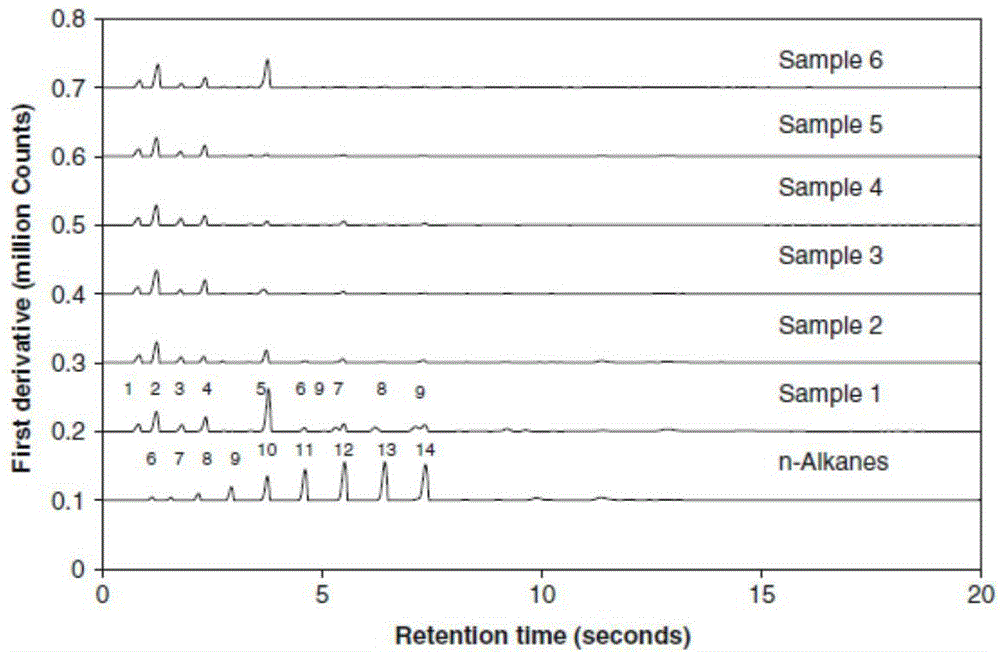

[0017] Before officially starting the blending, it is first necessary to measure the smell of the blended wine samples and various base wines respectively, and obtain such image 3 odor spectrum. image 3 Shown are the odor spectra of various years of liquor. The main macromolecular components that determine its flavor are expanded on the spectrum according to the number of carbon atoms. Based on fingerprints, each wine has a unique odor profile.

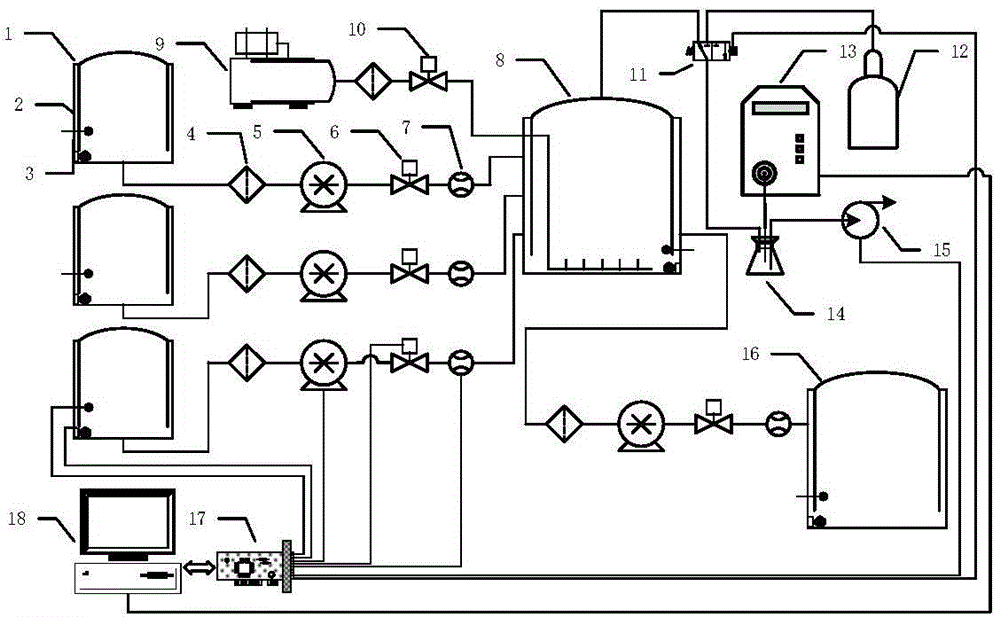

[0018] According to the blending process figure 2 , first carry out odor determination on the small sample and the base wine respectively, and store the results in the computer database for management and recall at any time. When the official blending starts, the pre-blending is carried out according to the proportion provided by the sample, and the blending ratio is determined by figure 1 The flow sensor 7 and the liquid solenoid v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com