Semi-synthetic metal wire drawing lubricant liquid and preparation method thereof

A metal wire drawing and semi-synthetic technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of easy scars on the surface of the metal wire, fast loss of wire drawing dies, easy corruption and deterioration, etc., to inhibit the reproduction of bacteria, easy to operate, Effect of improving surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

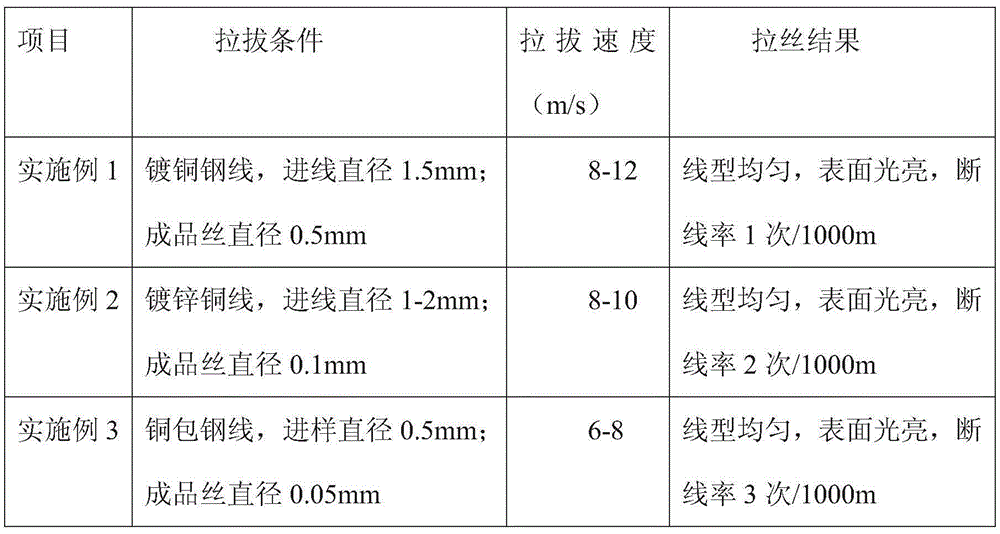

Examples

Embodiment 1

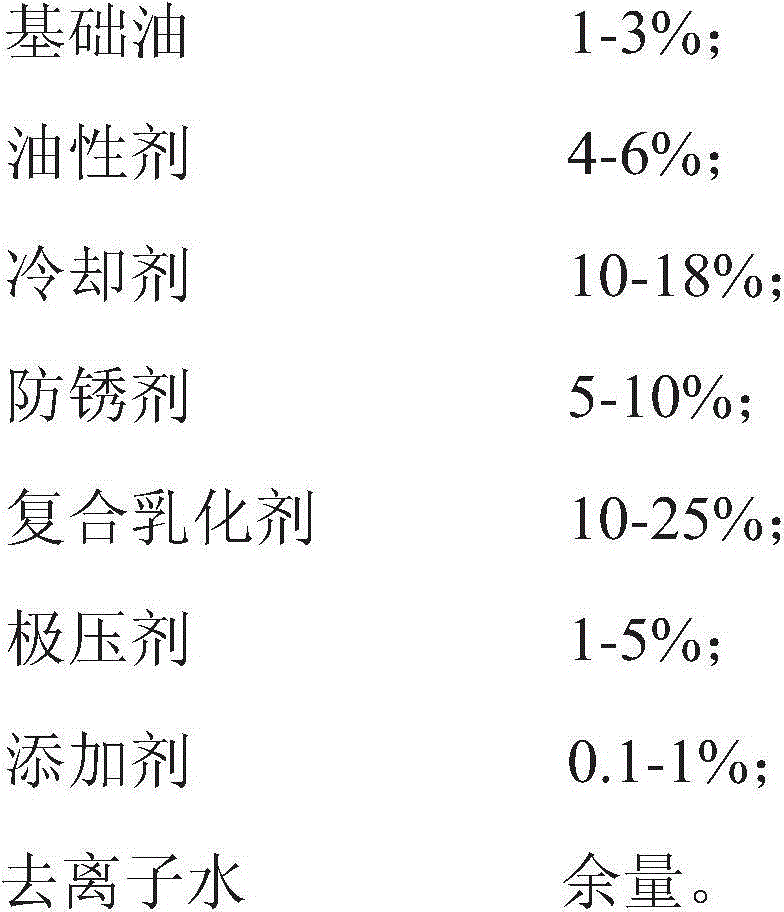

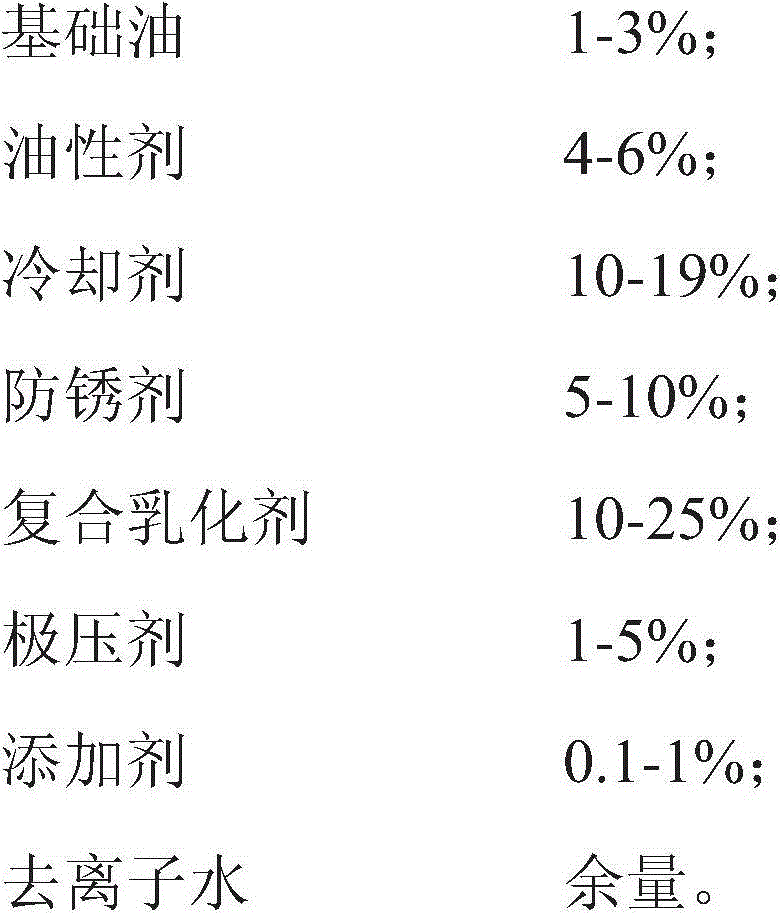

margin

[0026] The production method of above-mentioned metal wire drawing lubricant, concrete operation steps are as follows:

[0027] 1) Mix 26# mineral oil, ethylene bisoleic acid amide, oleic acid diethanolamide, oleyl alcohol polyoxyethylene ether phosphate, glycerin, and oleyl alcohol according to the weight ratio, and stir to disperse evenly;

[0028] 2) Take diethylenetriamine phosphate, water and the solution in step (1) and mix them, stir rapidly to make them evenly dispersed;

[0029] 3) Slowly add oleyl alcohol polyoxyethylene ether and oleylamine polyoxyethylene ether, and stir while adding to make it fully emulsified to form a transparent liquid;

[0030] 4) Add polyether modified silicone oil and bactericide MBM to the above transparent liquid in proportion, and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com