A stabilizer for heavy metal compound polluted soil and preparation method thereof

A technology of compound pollution and stabilizer, applied in the field of soil remediation, can solve the problems of insignificant stabilization effect, promotion of arsenic release, and poor buffering capacity, so as to overcome the poor stabilization effect, realize resource utilization, and reduce leaching concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Choice of contaminated soil

[0048] The soil sample was collected from a contaminated site in Gansu. The basic properties of the soil are shown in Table 1. The toxicity leaching test TCLP method was used to test the results: the leaching concentration of Pb in the soil sample was 40.37mg / L, and the leaching concentration of Zn was 229.39mg / L, the leaching concentration of Cd is 8.56mg / L, and the leaching concentration of As is 0.03mg / L; it is calculated that the total amount of the effective state of the heavy metals lead, zinc, cadmium and the effective state content of arsenic to be stabilized.

[0049] Table 1

[0050]

[0051] 2. Selection of raw materials:

[0052] (1) Sodium sulfide: commonly known as alkali sulfide, the chemical formula is Na 2 S·9H 2 O, content ≥98%, produced by Shanghai Tongya Chemical Technology Development Co., Ltd.;

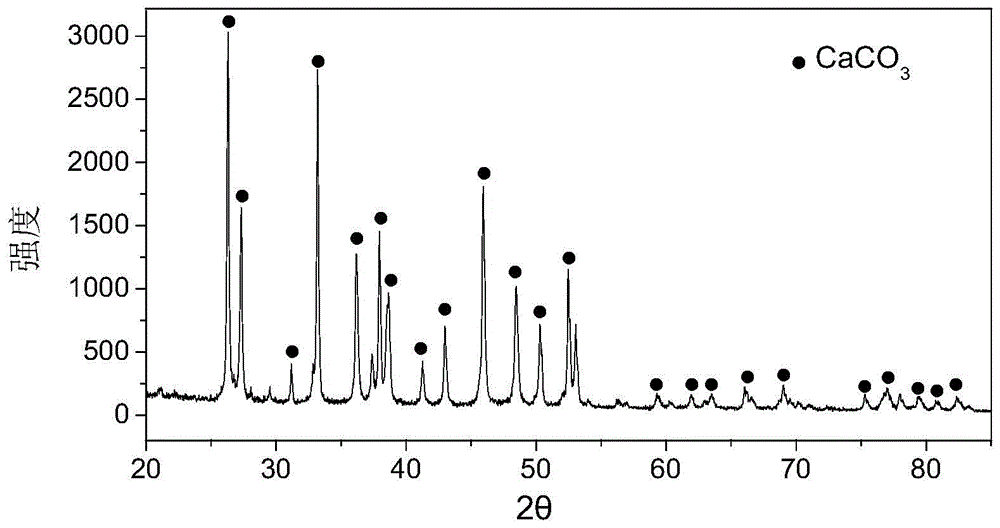

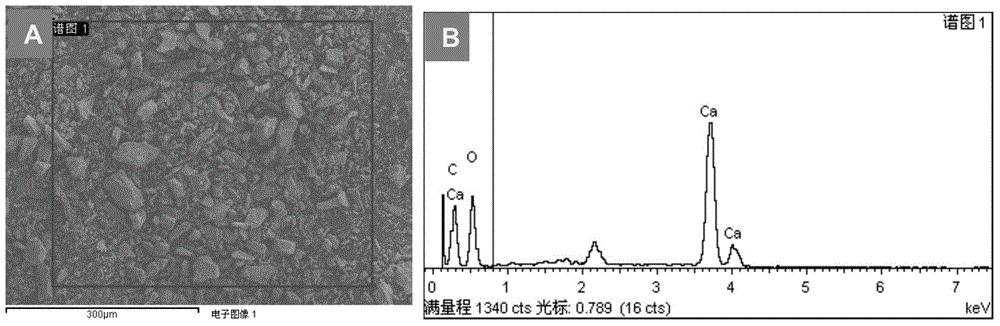

[0053] (2) Shell powder: Wash the shells with water, dry, and grind through a 400 mesh (38 μm) sieve. See the mineral compositio...

Embodiment 2

[0063] The selection of contaminated soil and raw materials is the same as in Example 1, and the formulation of stabilizer is different from that in Example 1.

[0064] Sodium sulfide is added at a molar ratio of 3 times the total amount of available heavy metals of lead, zinc, and cadmium. Shell powder is added at a molar ratio of 2 times the total available state of heavy metals of lead, zinc and cadmium. The addition of red mud is based on the iron in the red mud. It is added at a molar ratio of 4 times the effective state of arsenic.

[0065] The preparation method and use method of the stabilizer are the same as in Example 1, and the addition amount of the stabilizer is 5% of the weight of the soil. The uniformly mixed sample is sealed and placed in a standard curing box. The curing conditions are temperature 20±2°C and relative humidity 95%. After curing for 3 days, do toxicity leaching test. The test method is carried out according to the TCLP leaching method of the US Env...

Embodiment 3

[0068] The selection of contaminated soil and raw materials is the same as that of Example 1, and the formulation of stabilizers is different from that of Examples 1 and 2.

[0069] Sodium sulfide is added at a molar ratio of 6 times the total effective state of heavy metals of lead, zinc, and cadmium. Shell powder is added at a molar ratio of 4 times the total effective state of heavy metals of lead, zinc, and cadmium. The addition of red mud is based on red mud. It is added at a molar ratio of 8 times the effective state of iron and arsenic.

[0070] The preparation method and use method of the stabilizer are the same as in Example 1, and the addition amount of the stabilizer is 10% of the weight of the soil. The uniformly mixed sample is sealed and placed in a standard curing box. The curing conditions are temperature 20±2°C and relative humidity 95%. After curing for 3 days, do toxicity leaching test. The test method is carried out according to the TCLP leaching method of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com