Waterborne epoxy modified second order reaction type waterproof binding material and preparation method

A second-order reaction and bonding material technology, applied in the direction of epoxy resin glue, asphalt material adhesive, adhesive, etc., can solve the problems of failure to bond the upper and lower interface layers, high cost, unenvironmental protection, etc., to solve the problem of cost High, strengthen the bonding effect, convenient for industrial production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

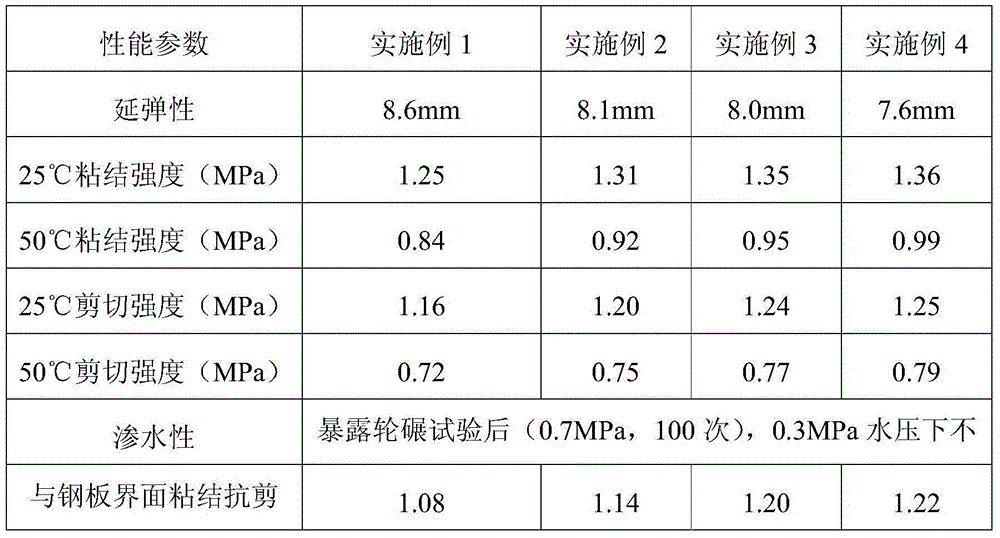

Examples

Embodiment 1

[0034] 1) Preparation of component A of the second-order reaction waterproof adhesive material

[0035] Emulsified asphalt by mass ratio: water-based epoxy resin: o-hydroxybenzoic acid: emulsifier: defoamer: stabilizer=100:10:0.5:0.8:0.1:1, select emulsified asphalt, water-based epoxy resin, o-hydroxybenzoic acid Benzoic acid, emulsifier, defoamer and stabilizer, spare;

[0036] Add emulsified asphalt into the container first, adjust the pH to 4.5 with hydrochloric acid, add water-based epoxy resin, o-hydroxybenzoic acid, emulsifier, defoamer and stabilizer while stirring manually, and continue stirring manually for 5 minutes until the mixture is uniform. Then put the stator of the high-speed shearing machine into the mixture, adjust the rotation speed to 200 rpm, turn on the switch to shear, about 30 minutes, and obtain the second-order reaction waterproof adhesive material A component.

[0037] 2) Construction of the second-order reaction waterproof bonding material

[003...

Embodiment 2

[0048] 1) Preparation of component A of the second-order reaction waterproof adhesive material

[0049] Emulsified asphalt by mass ratio: water-based epoxy resin: o-hydroxybenzoic acid: emulsifier: defoamer: stabilizer=100:12:0.7:1.1:0.25:1.5, choose emulsified asphalt, water-based epoxy resin, o-hydroxyl Benzoic acid, emulsifier, defoamer and stabilizer, spare;

[0050] Add emulsified asphalt into the container first, adjust the pH to 5.0 with hydrochloric acid, add water-based epoxy resin, o-hydroxybenzoic acid, emulsifier, defoamer and stabilizer while stirring manually, and continue stirring manually for 6 minutes until the mixture is uniform. Then put the stator of the high-speed shearing machine into the mixture, adjust the rotation speed to 250 rpm, turn on the switch to shear, about 35 minutes, and obtain the second-order reaction waterproof adhesive material A component.

[0051]2) Construction of the second-order reaction waterproof bonding material

[0052] Before...

Embodiment 3

[0062] 1) Preparation of component A of the second-order reaction waterproof adhesive material

[0063] Emulsified asphalt by mass ratio: water-based epoxy resin: o-hydroxybenzoic acid: emulsifier: defoamer: stabilizer=100:15:1.0:1.5:0.4:2, choose emulsified asphalt, water-based epoxy resin, o-hydroxyl Benzoic acid, emulsifier, defoamer and stabilizer, spare;

[0064] Add emulsified asphalt into the container first, adjust the pH to 5.5 with hydrochloric acid, add water-based epoxy resin, o-hydroxybenzoic acid, emulsifier, defoamer and stabilizer while stirring manually, and continue stirring manually for 8 minutes until the mixture is uniform. Then put the stator of the high-speed shearing machine into the mixture, adjust the rotation speed to 300 rpm, turn on the switch to shear, about 40 minutes, and obtain the second-order reaction waterproof adhesive material A component.

[0065] 2) Construction of the second-order reaction waterproof bonding material

[0066] Before c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com