An alkali-resistant anti-cracking exterior wall paint

An exterior wall paint and anti-cracking technology, applied in the direction of coating, etc., can solve problems such as peeling off, exterior wall paint cracking, and affecting the effect of exterior wall decoration, etc., to achieve the effect of good hardness and strong paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

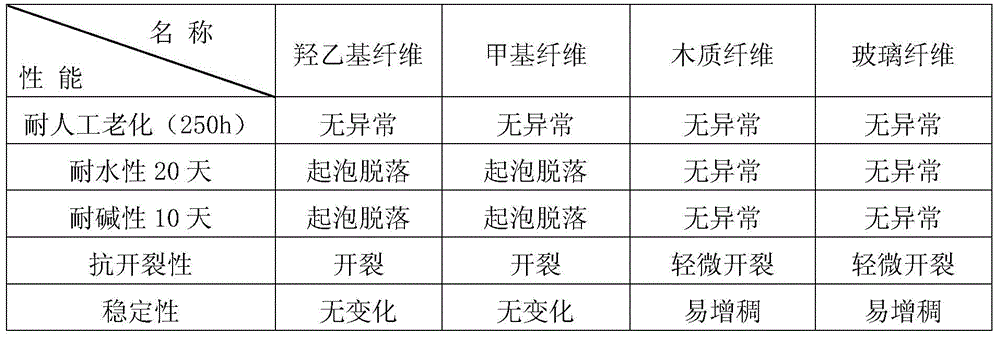

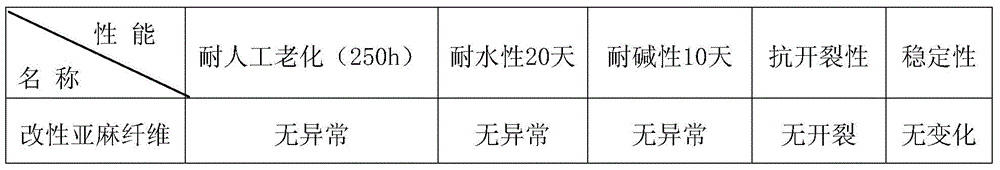

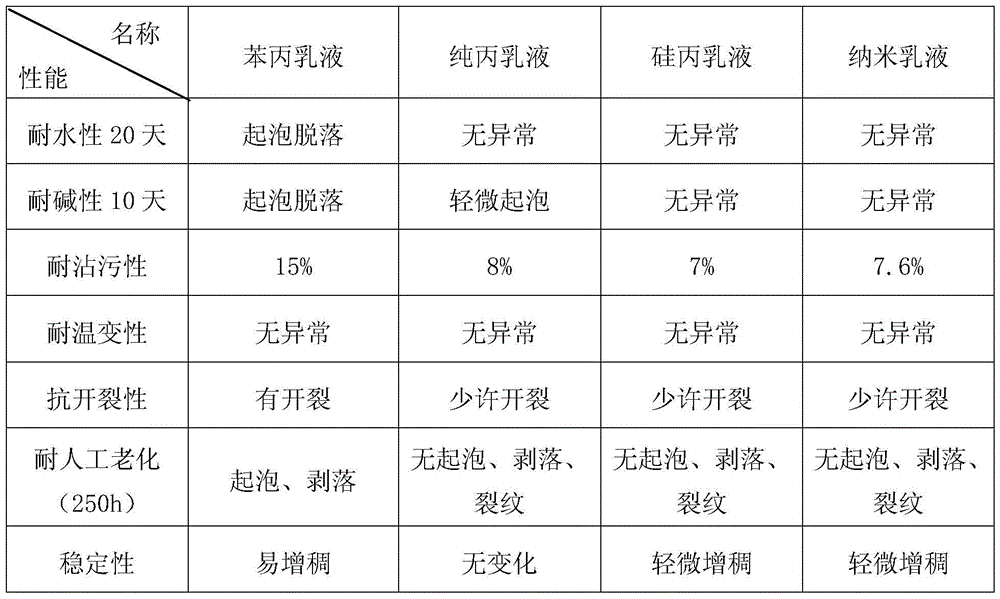

Method used

Image

Examples

Embodiment 1

[0045] An anti-alkali and anti-cracking exterior wall paint, which is uniformly prepared by mixing and stirring the following raw materials in parts by weight. The components are: 32 parts of modified composite emulsion, 0.25 part of modified flax fiber, and 0.65 part of hydroxyethyl cellulose , 2 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate (Texanol), 2 parts of propylene glycol, 2-amino-2-methyl-1-propanol (AMP-95) 0.15 parts, 50 parts of pigments and fillers, 0.5 parts of defoamer (BYK-033), 0.3 parts of antifungal agent, 0.25 parts of preservative, and 11.9 parts of water.

[0046] Wherein, the modified composite emulsion is prepared through the following steps: sequentially add 5 parts of water and 58 parts of pure acrylic emulsion into an interlayer stirred tank, then add 3 parts of water repellent, 31 parts of silicon acrylic emulsion, emulsifying 2 parts of agent, 1 part of defoamer, just stir well.

Embodiment 2

[0048] An anti-alkali and anti-cracking exterior wall paint, which is prepared by mixing the following raw materials in parts by weight: 30 parts of modified composite emulsion, 0.2 part of modified flax fiber, 0.5 part of hydroxyethyl cellulose, 2,2,4-tri 1.5 parts of methyl-1,3-pentanediol monoisobutyrate (Texanol), 1.5 parts of propylene glycol, 0.15 parts of 2-amino-2-methyl-1-propanol (AMP-95), 40 parts of pigments and fillers, Defoamer (BYK-033) 0.4 parts, antifungal agent 0.3 parts, preservative 0.2 parts, water 10 parts.

[0049] Wherein, the modified composite emulsion is made through the following steps: 2 parts of water and 55 parts of pure acrylic emulsion are sequentially added into an interlayer stirred tank, and then 1 part of water-repellent agent, 28 parts of silicon-acrylic emulsion, emulsified 1 part of antiseptic, 1 part of preservative, just stir well.

Embodiment 3

[0051] An anti-alkali and anti-cracking exterior wall paint, which is prepared by mixing the following raw materials in parts by weight: 36 parts of modified composite emulsion, 0.5 part of modified flax fiber, 0.7 part of hydroxyethyl cellulose, 2,2,4-tri 2 parts of methyl-1,3-pentanediol monoisobutyrate (Texanol), 2 parts of propylene glycol, 0.25 parts of 2-amino-2-methyl-1-propanol (AMP-95), 60 parts of pigments and fillers, Defoamer (BYK-033) 0.6 parts, antifungal agent 0.8 parts, preservative 0.3 parts, water 12 parts.

[0052] Wherein, the modified composite emulsion is made through the following steps: 6 parts of water and 60 parts of pure acrylic emulsion are sequentially added into the interlayer stirred tank, and then 4 parts of water-repellent agent, 33 parts of silicon-acrylic emulsion, emulsified 3 parts of antifungal agent and 2 parts of antifungal agent, just stir well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com