Glass fiber reinforced polyamide 66 composite material, and preparation method and application thereof

A composite material and nylon technology, applied in the field of nylon 66 composite materials, can solve the problems of unsatisfactory alcoholysis resistance and achieve good alcoholysis resistance, good aging protection, and good lubrication and mold release effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

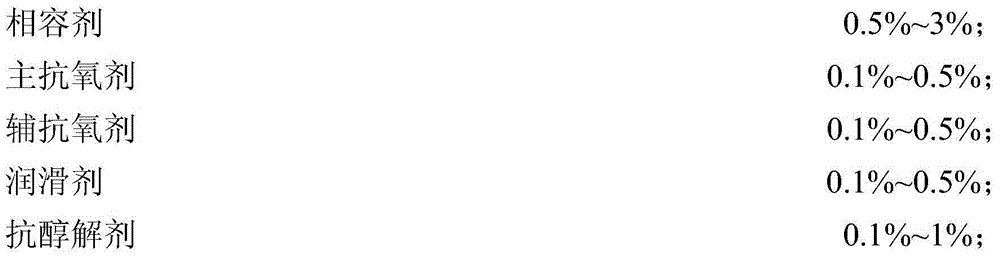

Method used

Image

Examples

Embodiment 1~5 and comparative example 1

[0032] Put the dried nylon 66, coupling agent, compatibilizer, primary antioxidant, secondary antioxidant, lubricant, anti-alcoholysis agent into a high-speed mixer and mix at high speed (500 rpm) for 4 minutes, From the first feeder (main feeder) to the twin-screw extruder, glass fiber is fed into the twin-screw extruder from the second feeder (side feeder) to extrude and granulate, the temperature from the feed section to the head The setting order is: 250~260℃, 260~270℃, 270~280℃, 270~280℃, 270~280℃, 270~280℃, 265~275℃, 260~265℃, the temperature of the die head is 260~265℃, the negative pressure at the vacuum port is not less than 0.04MPa, after extrusion, it is water-cooled, pelletized, and then packaged to obtain a glass fiber reinforced nylon 66 composite material, which can be used to prepare the engine intake manifold.

[0033] The formulations of Examples 1-5 and Comparative Example 1 are shown in Table 1 below.

Embodiment 6~10 and comparative example 2、3

[0045] Put the dried nylon 66, coupling agent, compatibilizer, main antioxidant, auxiliary antioxidant, lubricant, anti-alcoholysis agent into a high-speed mixer and mix at high speed (1000 rpm) for 4 minutes, From the first feeder (main feeder) to the twin-screw extruder, glass fiber is fed into the twin-screw extruder from the second feeder (side feeder) to extrude and granulate, the temperature from the feed section to the head The setting order is: 250~260℃, 260~270℃, 270~280℃, 270~280℃, 270~280℃, 270~280℃, 265~275℃, 260~265℃, the temperature of the die head is 260~265℃, the negative pressure at the vacuum port is not less than 0.4MPa, after extrusion, it is water-cooled, pelletized, and then packaged to obtain a glass fiber reinforced nylon 66 composite material, which can be used to prepare engine intake manifolds.

[0046] The formulations of Examples 6-10 and Comparative Examples 2 and 3 are shown in Table 4 below.

[0047] The formula of table 4, embodiment 6~10 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com