A 120 ℃ aging butady/polyvinyl chloride rubber composition

A polyvinyl chloride rubber and composition technology, applied in the rubber field, can solve the problems of collapsed rubber hose, reduced rubber strength and other mechanical properties, blocked pipelines, etc., and achieves stable volume change, improved safety and service life, and oil resistance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

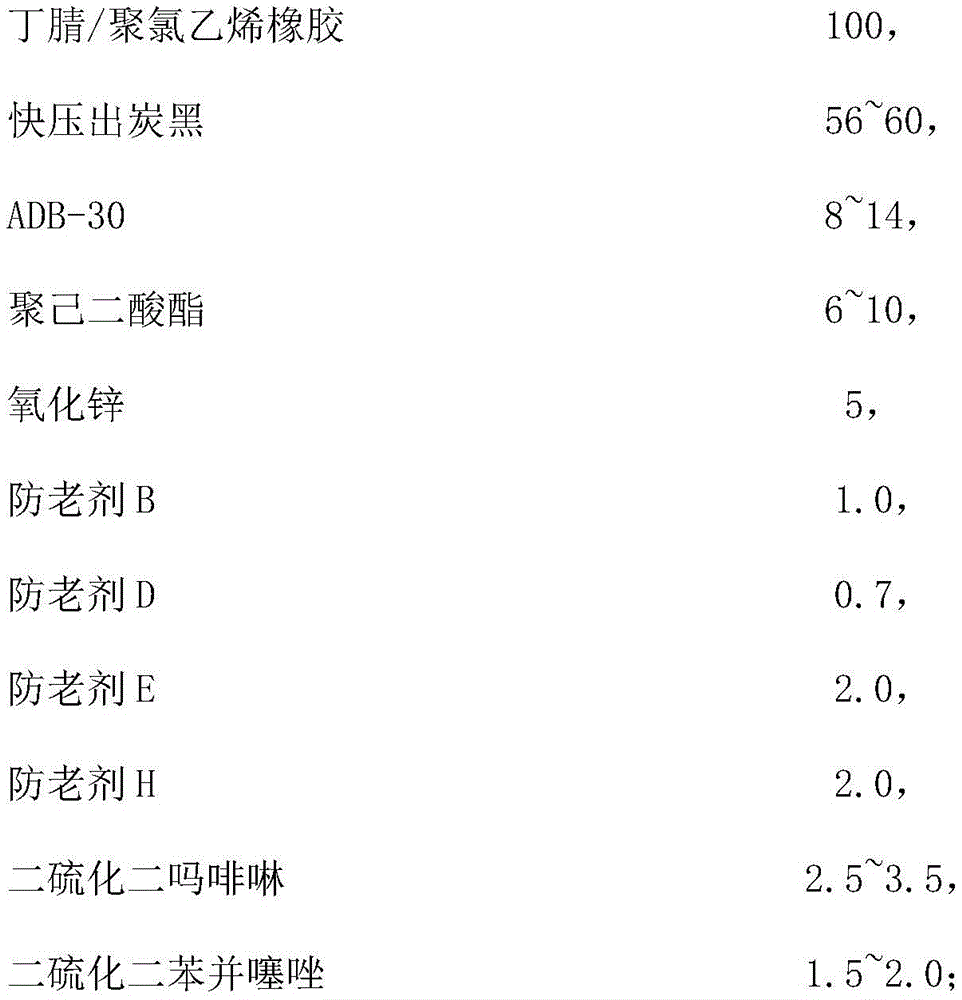

[0013] In parts by mass

[0014] components

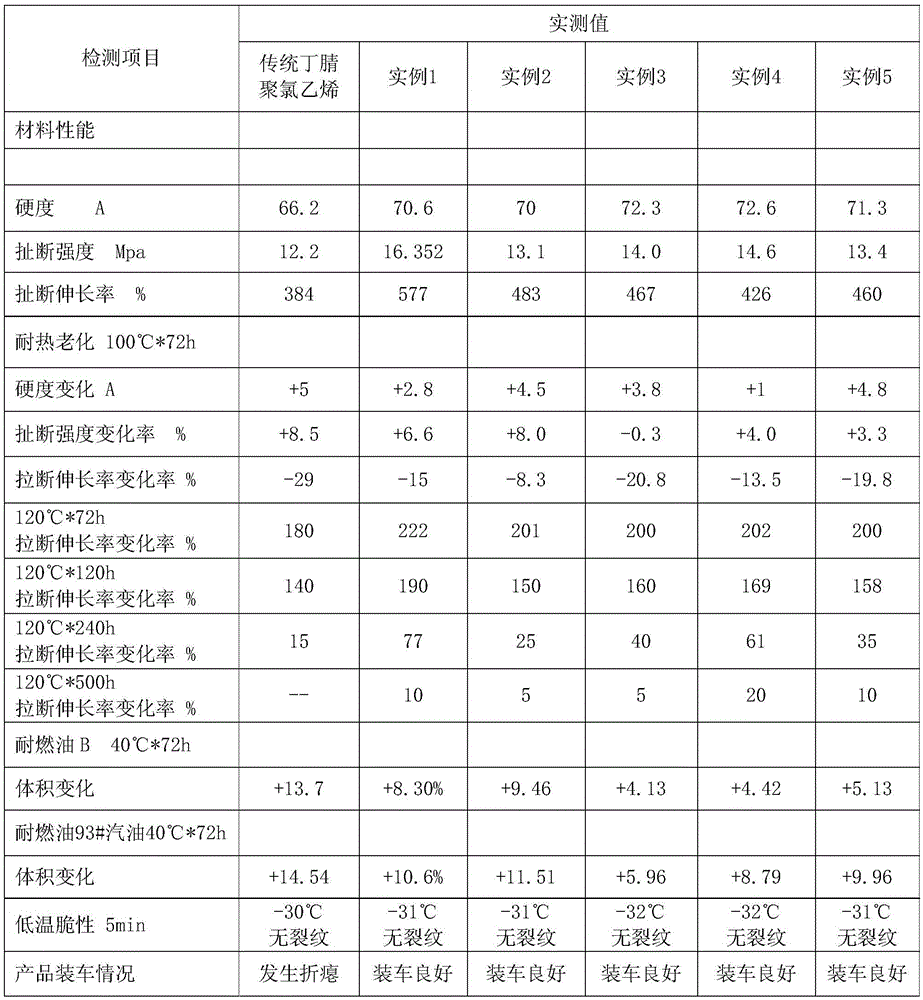

Example 1

Example 2

Example 3

Example 4

Example 5

Nitrile / PVC Rubber

100

100

100

100

100

quick press carbon black

50

55

56

60

58

Ether ester ADB-30

8

10

10

14

8

Polyadipate

8

8

10

6

10

5

5

5

5

5

Antiager B

1.0

1.0

1.0

1.0

1.0

Antiager D

0.7

0.7

0.7

0.7

0.7

Antiager E

2.0

2.0

2.0

2.0

2.0

Antiager H

2.0

2.0

2.0

2.0

2.0

Dimorpholine disulfide

2.5

3.0

3.5

3.0

3.0

dibenzothiazole disulfide

1.5

2.0

1.5

2.0

2.0

total

180.7

188.7

191.7

195.7

191.7

[0015] The nitrile / polyvinyl chloride rubber is domestically produced 41% to 43% nitrile / polyvinyl chloride rubber with medium and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com