Multi-layer spraying and burning evaporation wall type supercritical water oxidation reactor

A supercritical water oxidation and evaporation wall technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of difficult industrial scale-up, hanging on the wall, and small processing capacity, so as to reduce the consumption , reduce the range, reduce the effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

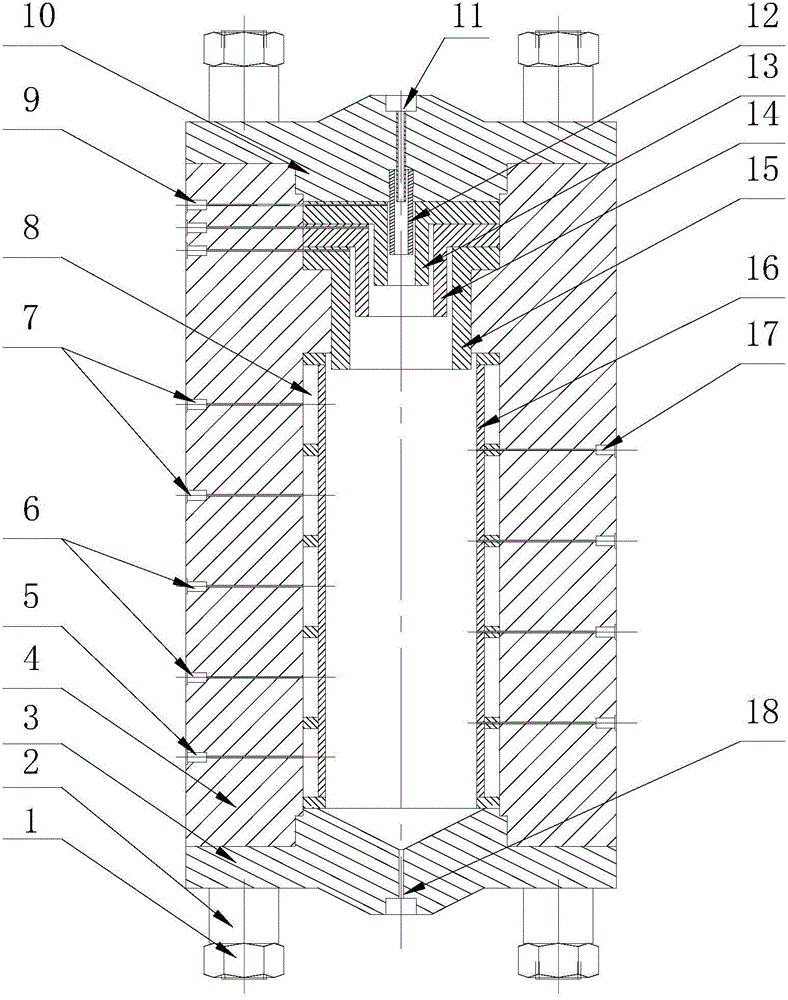

[0024] A multi-layer spray-fired evaporating wall supercritical water oxidation reactor, mainly composed of a cylinder body 4, an upper end cover 10, a lower end cover 3, a burner and an evaporation wall 16, and the cylinder body, the upper end cover, and the lower end cover are respectively fixed and installed , An evaporation wall is installed in the cylinder, and a reactant outlet 18 is formed on the lower end cover.

[0025] The innovation of this reactor is that the burner is a multi-layer burner, and the multi-layer burner consists of a central burner 12 installed in the center of the end cover and a first lower layer burner 13 located at the bottom of the first burner, The second lower layer burner 14 and the third lower layer burner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com