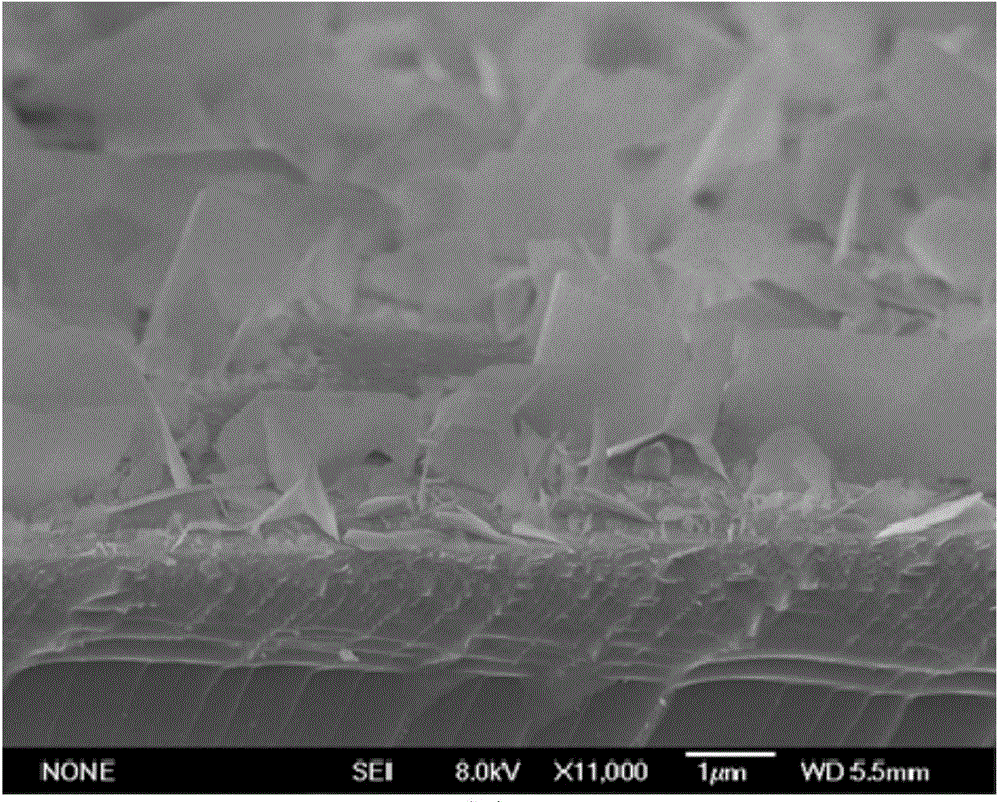

Method for preparing cobaltous oxide electrode with nanosheet structure

A cobalt oxide and nanosheet technology, applied in the manufacture of cobalt oxide/cobalt hydroxide, hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problem of low specific capacitance, improve the charging and discharging rate, and facilitate industrial production. , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Embodiment 1: A method for preparing a nanosheet structure cobalt oxide electrode described in this embodiment is specifically carried out according to the following steps:

[0019] 1. Put the Si substrate in an acetone solution and ultrasonically clean it for 10-20 minutes, and then use magnetron sputtering equipment to prepare a Co coating on the Si substrate to obtain a Co-coated silicon wafer;

[0020] 2. Place the Co-coated silicon wafer in the plasma-enhanced chemical vapor deposition vacuum device, evacuate to a pressure below 5Pa, pass in argon gas, adjust the flow rate of the argon gas to 10sccm-50sccm, and adjust the plasma-enhanced chemical vapor deposition vacuum The pressure in the device is 100Pa~1000Pa, and under the pressure of 100Pa~1000Pa and argon atmosphere, the temperature is raised to 500℃~800℃ within 25min;

[0021] 3. Introduce oxygen, adjust the gas flow rate of oxygen to 10sccm, adjust the gas flow rate of argon to 50sccm~90sccm, adjust the pre...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that: in Step 1, a Co coating with a thickness of 10 nm˜1000 nm is prepared on the Si substrate by using a magnetron sputtering device. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that in step 1, a Co coating with a thickness of 100 nm is prepared on the Si substrate by using a magnetron sputtering device. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com