Device and method for producing magnesium sulfate

A technology of magnesium sulfate and desulfurization tower, applied in the direction of magnesium sulfate, energy input, etc., can solve the problems of difficult maintenance, high production cost per ton of ore, and too much steam consumed by magnesium sulfate, so as to save the operation cost of desulfurization and reduce the production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

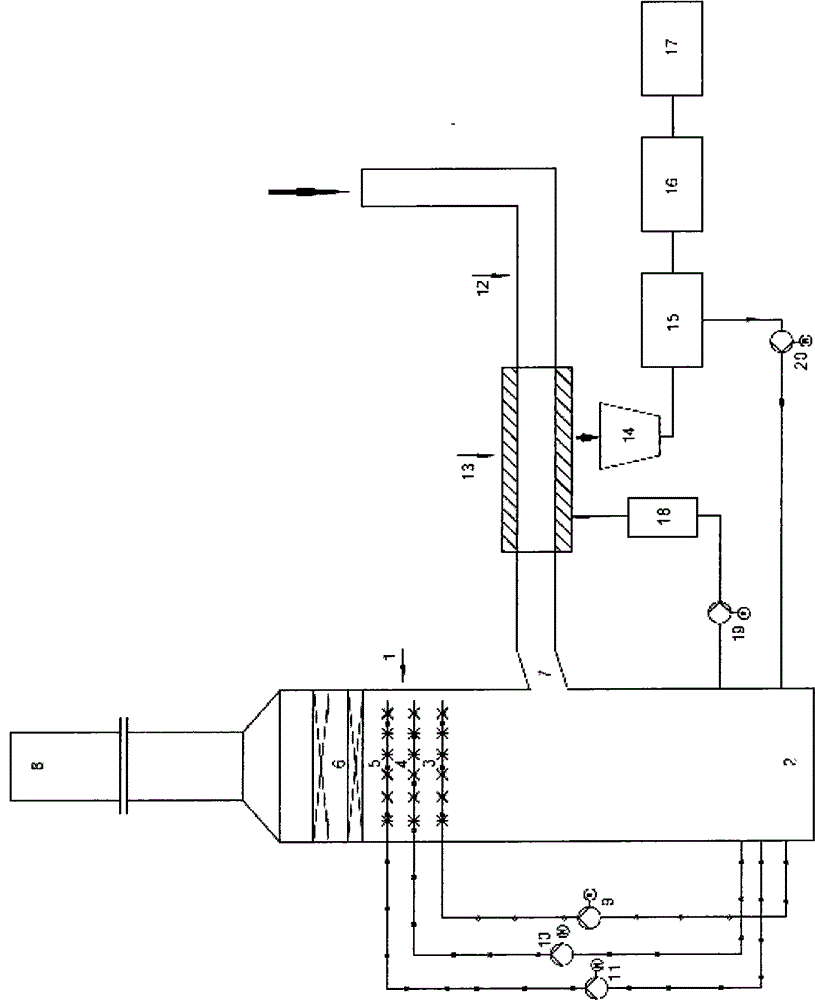

[0055] use figure 1 Described device manufactures a specific embodiment of magnesium sulfate, and described method comprises the steps:

[0056] a. The flue gas enters the interior of the desulfurization tower 1 from the flue gas inlet 7 through the flue, and passes through the first-stage SO 2 Absorption spray layer 3, secondary SO 2 Absorption spray layer 4, three-stage SO 2 After the desulfurization absorption reaction is carried out in the absorption spray layer 5, it is finally dehydrated and defogged by the demister 6, and then directly discharged through the flue gas outlet 8 of the top chimney;

[0057] b. The absorption liquid pumped out by the slurry circulation tank 2 is filtered by the discharge pump 19 and filtered by the filter 18, and then enters the flue heat exchanger 13 for evaporation and concentration, and the crystal-containing material after evaporation and concentration is sent to the crystallization tank 14;

[0058] C, the solid-liquid mixture that ...

Embodiment 1

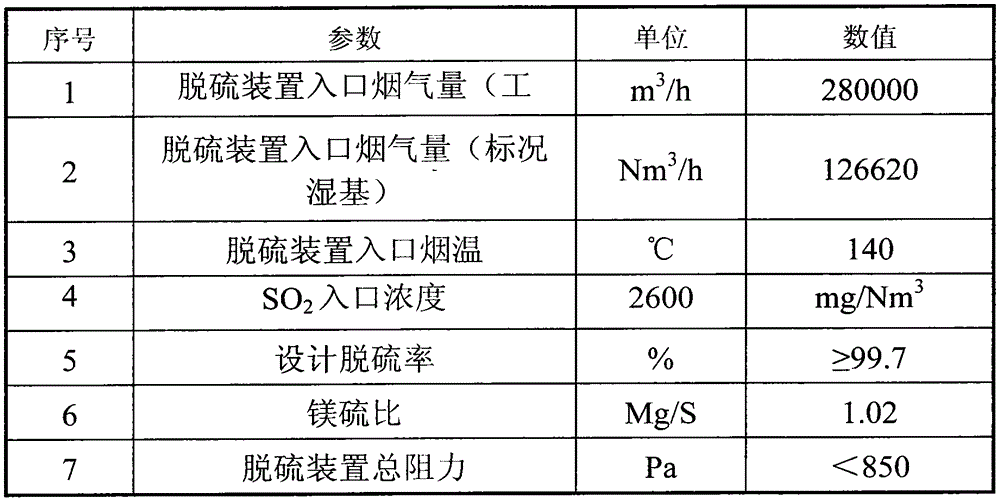

[0061] Example 1 Sintering machine flue gas desulfurization project

[0062] Step 1: Add industrial tap water to the magnesium oxide powder to make magnesium hydroxide slurry, and send it to the circulating slurry pool 2 at the bottom of the desulfurization tower 1 .

[0063] Step 2: Make the sintering machine flue gas (with an oxygen content of 13vt%) with a flow velocity of 2.5-3.5m / s and a temperature of 110-180°C enter the desulfurization tower 1 from the flue gas inlet 7 of the desulfurization tower 1 through the flue 12 .

[0064] Step 3: Pass Level 1 SO 2 Absorption circulation pump 9, secondary SO 2 Absorption circulation pump 10, three-stage SO 2 The absorption circulating pump 11 sends the slurry in the circulating slurry pool 2 into the first-stage SO2 Absorption spray layer 3, secondary SO 2 Absorption spray layer 4, three-stage SO 2 The absorption spray layer 5, after the absorption reaction, the slurry falls into the circulating slurry pool 2.

[0065] Ste...

Embodiment 2

[0078] Example 2 Coal-fired boiler flue gas desulfurization project

[0079] Step 1: Add industrial tap water to the magnesium oxide powder to make magnesium hydroxide slurry, and send it to the circulating slurry pool 2 at the bottom of the desulfurization tower 1 .

[0080] Step 2: Make the coal-fired boiler flue gas (with an oxygen content of 13vt%) with a flow velocity of 2.5-3.5m / s and a temperature of 110-180°C enter the desulfurization tower 1 from the flue gas inlet 7 of the desulfurization tower 1 through the flue 12 .

[0081] Step 3: Pass Level 1 SO 2 Absorption circulation pump 9, secondary SO 2 Absorption circulation pump 10, three-stage SO 2 The absorption circulating pump 11 sends the slurry in the circulating slurry pool 2 into the first-stage SO 2 Absorption spray layer 3, secondary SO 2 Absorption spray layer 4, three-stage SO 2 The absorption spray layer 5, after the absorption reaction, the slurry falls into the circulating slurry pool 2.

[0082] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com