Variable travel elevator

A technology of travel and elevators, applied in the field of elevators, can solve the problems of building construction elevators that cannot be equipped with more, and achieve the effect of improving safety and construction efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

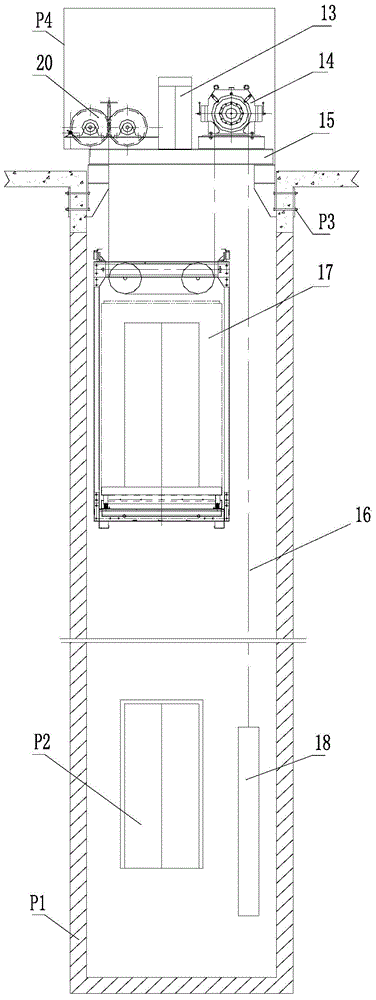

[0019] see Figure 1~4 , the embodiment of the present invention is provided with machine room, car 17, counterweight 18, wire rope group and wire rope retractable device 20 etc., machine room is provided with main frame 14, control cabinet 13 and main frame load beam 15 etc. figure 1 Among them, the mark P1 is the building well; the mark P2 is the hall door; the mark P3 is the embedded connector; the mark P4 is the rain cover of the machine room.

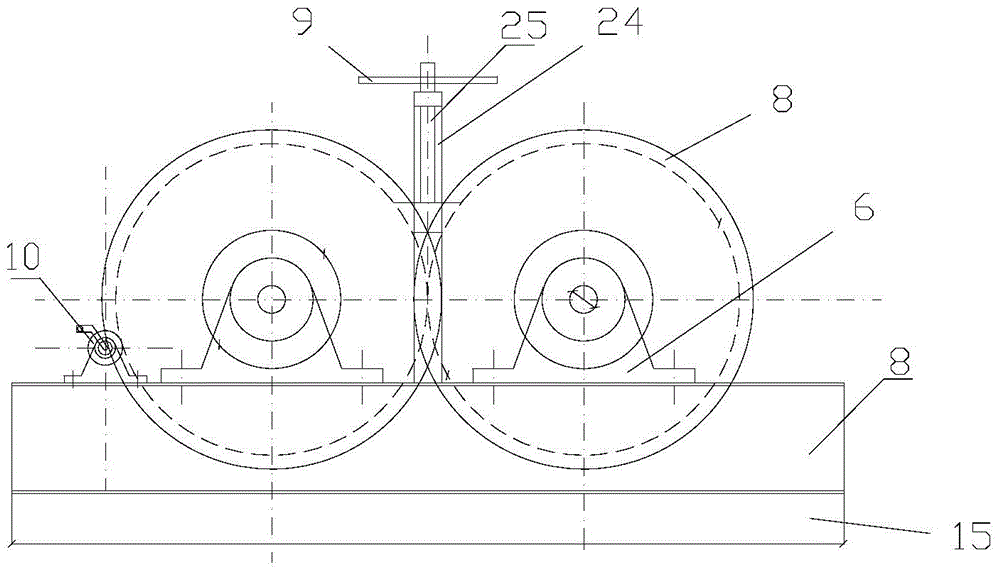

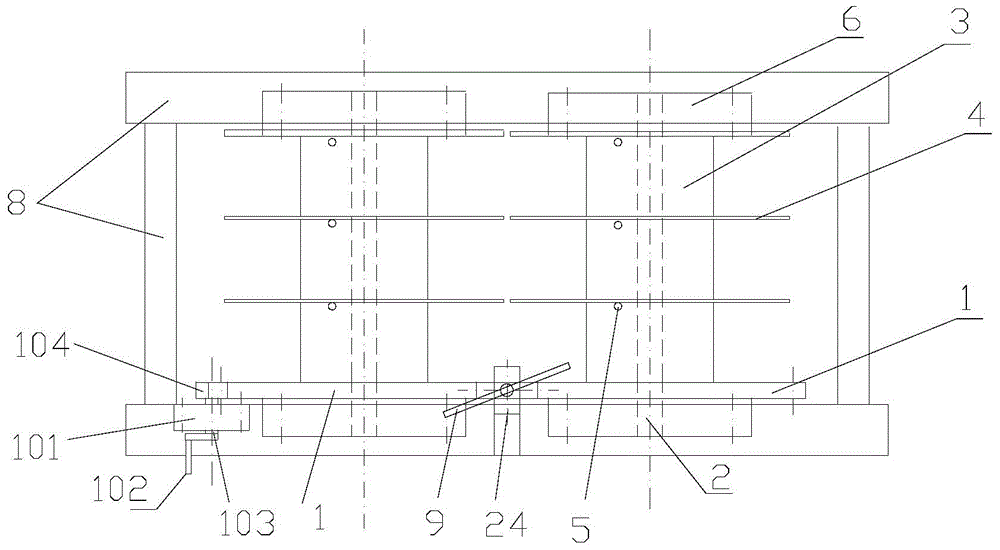

[0020] Wire rope retractable device 20 is installed on the main frame load-bearing beam 15 of machine room. The wire rope retracting device 20 is provided with a base 7, 2 wire rope reel cylinders 3, 2 gear discs 1, 2 gear disc shafts 2, a rope retaining disc 4, a gear disc locking mechanism and a gear disc Rotational direction control mechanism 10; 2 steel wire rope disc cylinders 3 are installed in parallel on the base 7, each gear disc shaft 2 is connected with 1 gear disc 1 and 1 steel wire rope disc cylinder 3, and the gear d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com