Ink cavity structure of an inkjet printer nozzle

A technology of inkjet printers and nozzles, which is applied in printing and other directions, and can solve problems such as mutual interference, inability to adjust the volume of ink chambers, and narrow variation range of ink droplet volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

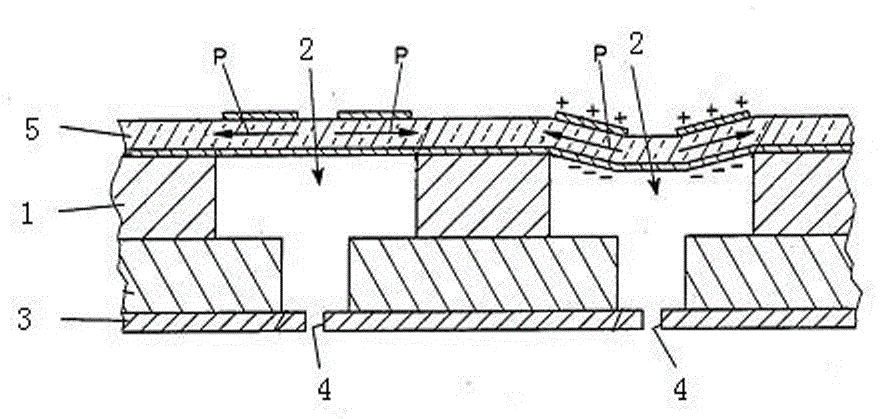

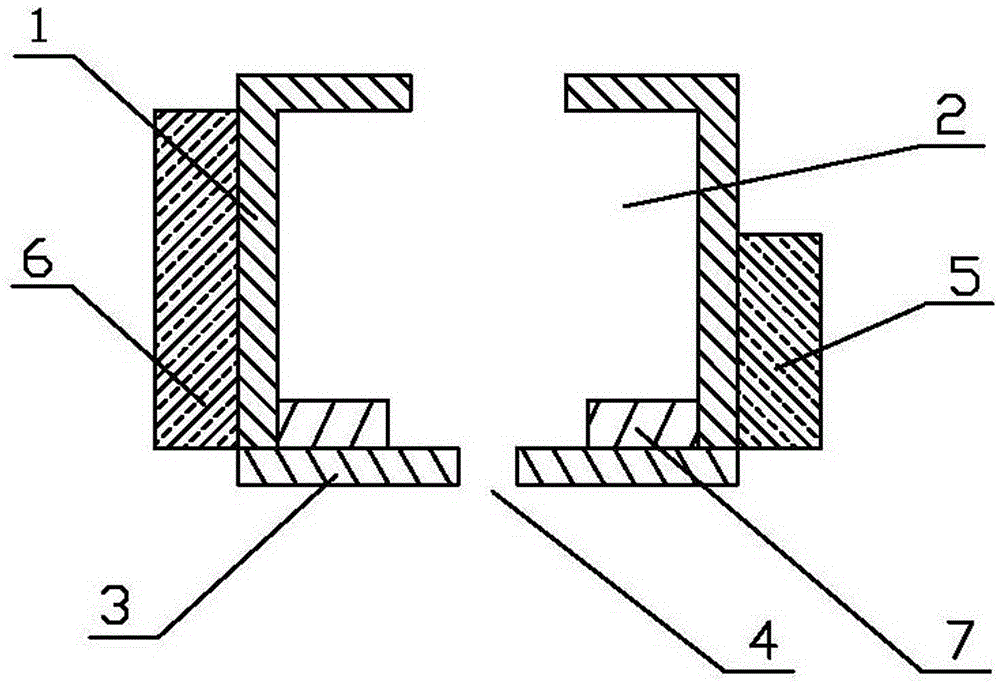

Embodiment 1

[0018] Figure 5 It is a cross-sectional view of the ink chamber as a single pressure chamber, and the arrow is the ink flow direction in the figure. As shown in the figure, the present invention includes an orifice plate 3, an orifice lining plate 7, an ink chamber plate 12, piezoelectric ceramics 5, piezoelectric The ceramic 6, the flexible circuit board 8, the flexible circuit board 9, and the ink inlet plate 10 are assembled by stacking them. Have the ink inlet hole 11 on the ink inlet plate 10, have the ink chamber 2 on the ink chamber plate 12 (this ink chamber 2 is actually surrounded by the hole here and the flexible circuit board of the ink chamber plate to form), the spray hole There are ink outlet holes 71 on the backing plate 7, and nozzle holes 4 for ejecting ink droplets are opened on the orifice plate 3, and the ink chamber and these holes form a pressure chamber. There is also a groove 71 on the nozzle liner 7, and a groove 101 on the ink inlet plate 10, and p...

Embodiment 2

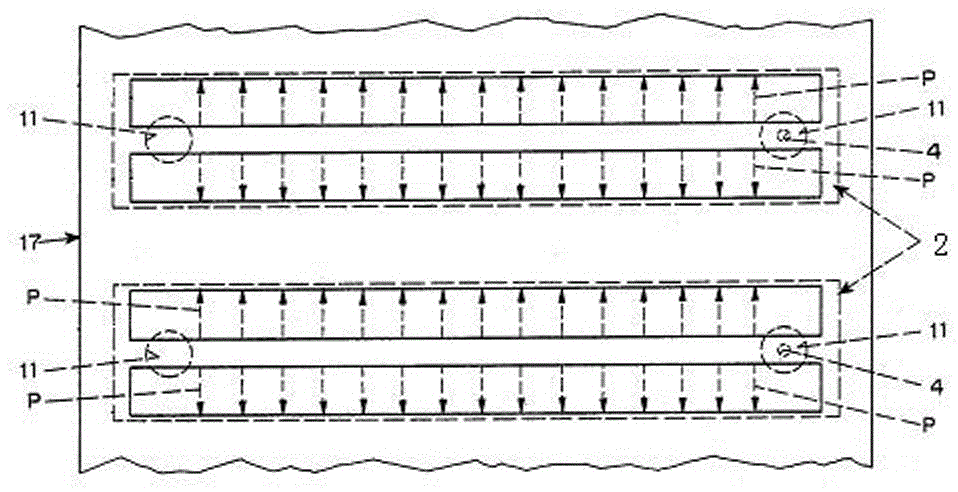

[0020] Image 6 It is a cross-sectional view of the ink chamber as a double pressure chamber. This embodiment is similar to Embodiment 1, except that there are 3 ink chamber plates, namely ink chamber plates 13, 14, and 15. These 3 ink chamber plates separate the ink chamber, There are two pressure chambers, namely pressure chamber 21 and pressure chamber 22, and a piece of piezoelectric ceramic is arranged on each pressure chamber. The two pressure chambers are divided into one large and one small by volume, the large piezoelectric ceramic 6 is installed on the side of the large pressure chamber 21, and the small piezoelectric ceramic 5 is installed on the side of the small pressure chamber 22. In this embodiment, the piezoelectric ceramic is PZT5, the width of the large piezoelectric ceramic 6 is 10 millimeters, the width of the small piezoelectric ceramic 5 is 5 millimeters, the voltage is 60-100 V, and the volume of the large pressure chamber 21 is 0.6 cubic millimeters. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com