Full-automatic printing machine with touch screen

A touch screen and printing machine technology, applied in printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of low automation and low production efficiency, and achieve the goals of improving production efficiency, saving production costs, and avoiding defective products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

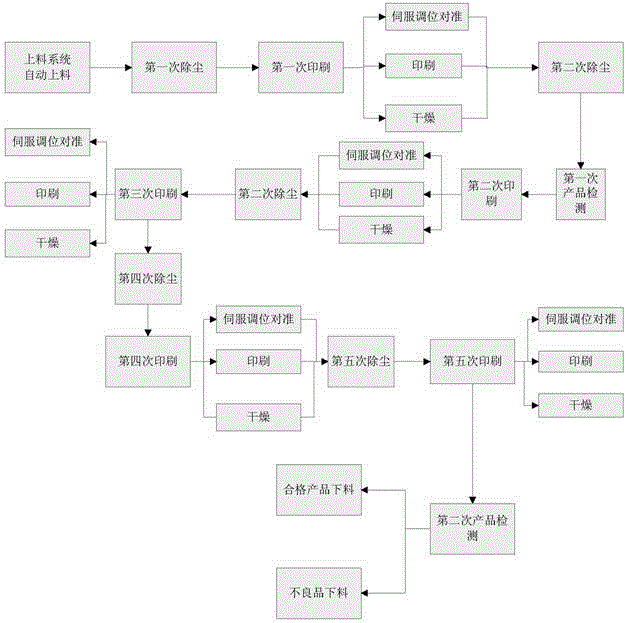

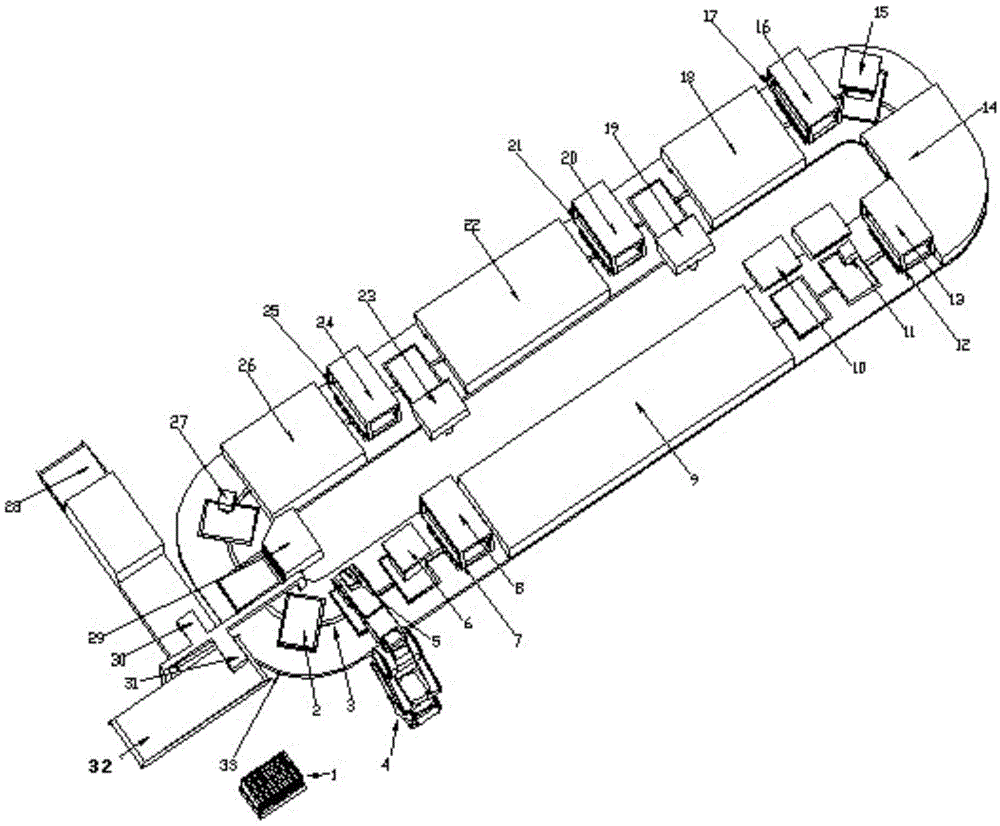

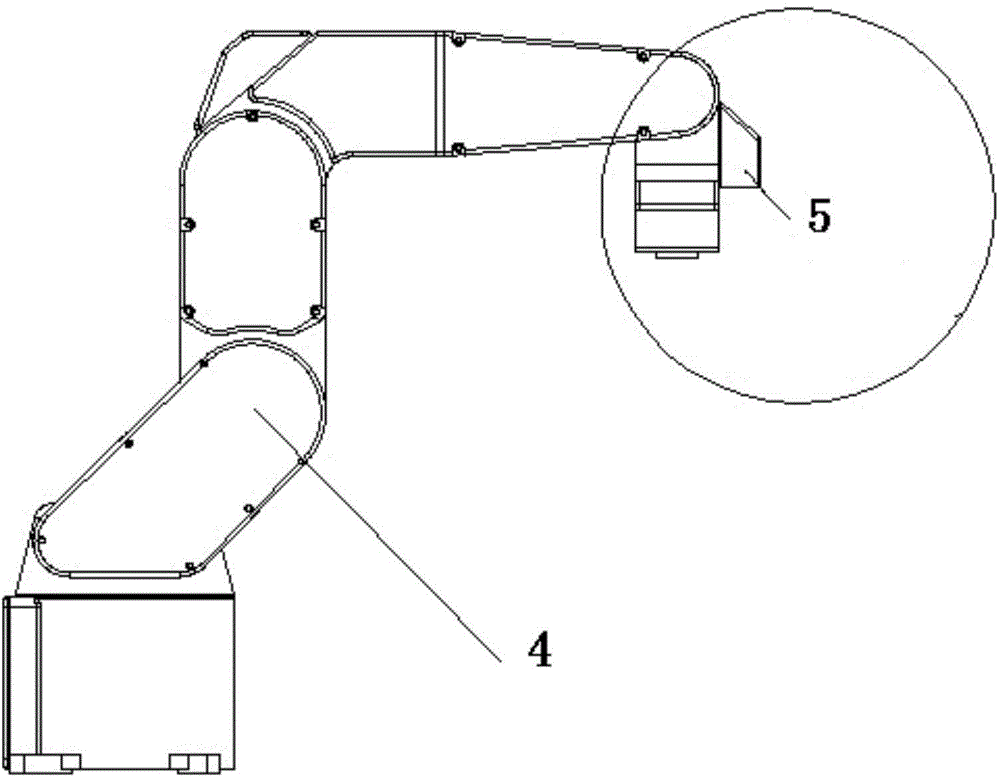

[0029] Take the mobile phone touch screen printing as an example below to illustrate the structure and working process of the present invention. Such as figure 2 , 3 As shown, the base 33 is equipped with base slide rails 6 and multiple sets of workbenches 2, and the worktables 2 and base slide rails 2 are slidingly matched, and can be docked at designated processing points by the action of the divider during the movement. The feeding device is composed of a manipulator 4 and a CCD detection device, and the CCD detection device is located at the front of the manipulator, such as image 3 shown. The manipulator 4 takes the touch screen out of the material cage and places it on the workbench 2. The CCD detection device 5 is responsible for feeding back the position information of the touch screen and feeding back the information to the control device. Workbench 5 performs servo adjustment on the touch screen on it to ensure that the touch screen is placed at the designated p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com