Light scattering type agricultural film as well as manufacturing method and application thereof

A manufacturing method and light scattering technology, which is applied in the agricultural field, can solve the problems of low direct light transmittance and achieve the effects of shortening the picking period, improving light efficiency, and high direct light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 (contrast)

[0058] Manufacture of light-scattering agricultural film with a thickness of 65 μm.

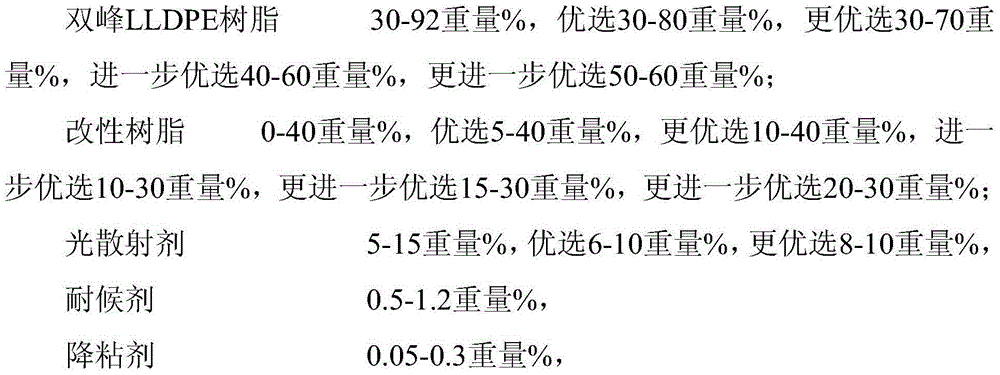

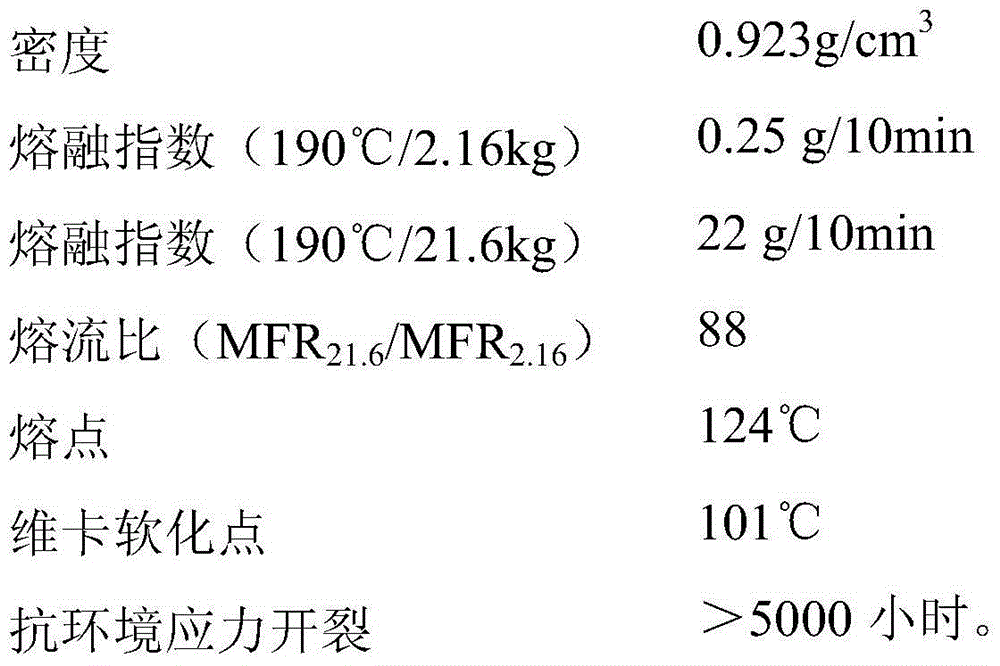

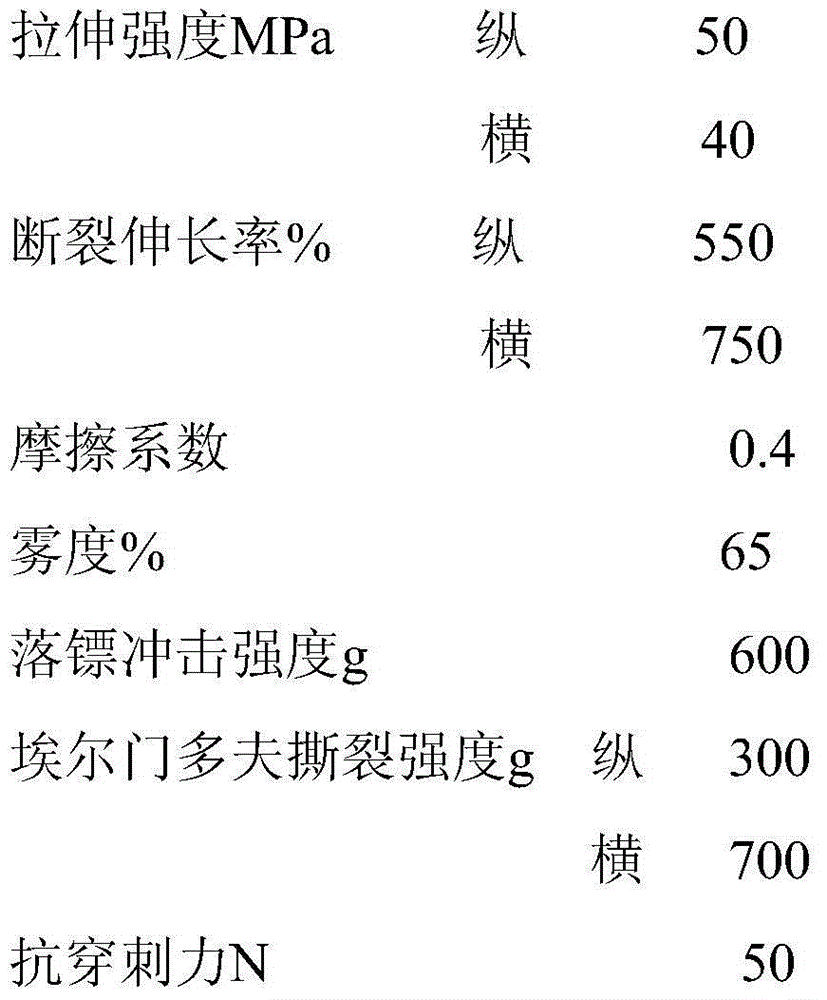

[0059] The formula and performance of the agricultural film are as follows:

[0060]

[0061] The manufacture method of described agricultural film is:

[0062] Table 1

[0063]

[0064] According to the ratio shown in Table 1, it is divided into three layers: inner, middle and outer layers. Each component is stirred in the mixer respectively, and after mixing evenly, it is made into a cylindrical film through a three-layer co-extrusion blown film unit, and is clamped by the upper traction roller. Tightly form a flat film, and make a scattering agricultural film after passing through the upper and lower traction rollers and winder. The speed, current, melt pressure and temperature of each layer of extruder are shown in Table 2 below. The outer barrel temperature is 210°C, the middle barrel temperature is 190°C, and the inner barrel temperature is 189...

Embodiment 2

[0067] Embodiment 2 (this application)

[0068] Manufacture of light-scattering agricultural film with a thickness of 68 μm.

[0069] The formula and performance of the agricultural film are as follows:

[0070]

[0071]

[0072] The manufacture method of described agricultural film is:

[0073] table 3

[0074]

[0075] According to the ratio shown in Table 3, it is divided into three layers: inner, middle and outer layers. Each component is stirred in the mixer respectively, and after mixing evenly, it is made into a cylindrical film through a three-layer co-extrusion film blowing unit, and passed through the upper traction roller. It is clamped to form a flat film, and the scattering type agricultural film is obtained after passing through the upper and lower traction rollers and the winder. The speed, current, melt pressure and temperature of each layer of extruder are shown in Table 4 below. The outer barrel temperature is 205°C, the middle barrel temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com