EPS (expandable polystyrene) foam cutting device

A cutting device and foam technology, applied in the field of foam processing, can solve the problems of low EPS foam cutting efficiency, inconvenient operation of loading and unloading EPS foam, etc., and achieve the effects of simple structure, low cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

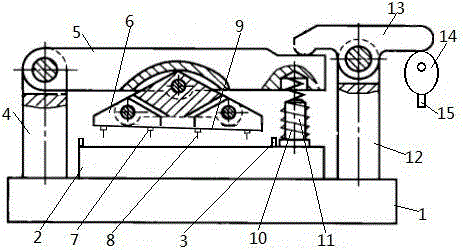

[0012] The reference signs in the drawings of the description include: base 1, cutting table 2, baffle plate 3, first column 4, moving plate 5, pressing block 6, cutter mounting seat 7, cutting knife 8, pressing block bottom surface 9, pressing block Spring 10, stage clip mounting column 11, second column 12, driving block 13, cam 14, turning handle 15.

[0013] as attached figure 1 Shown: base 1 is cuboid shape, is provided with cuboid cutting table 2 along its length direction on base 1, welds two baffle plates 3 respectively at the broad side of cutting table both sides, the length of each baffle plate 3 is equal to Equal to the broad side length of cutting table 2.

[0014] A first column and a second column are respectively arranged on both sides of the wide side of the cutting table 2, and the top of the first column is rotationally connected with one side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com