Drive shelter positioning and assembling equipment and assembling method

A technology of assembling equipment and assembling methods, which is applied in assembly machines, metal processing equipment, transportation and packaging, etc., can solve the problems of fixed size, large cab size, and long time spent on molds, so as to ensure accuracy and precise positioning. Assembly, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

[0018] The frame of the cab can be disassembled into the base, the longitudinal ribs fixed at the four corners of the base and the beams connecting the tops of the four longitudinal ribs. According to different specifications of engineering vehicles, split parts of different sizes and shapes can be produced, and the The components are assembled and fixed according to the preset interface.

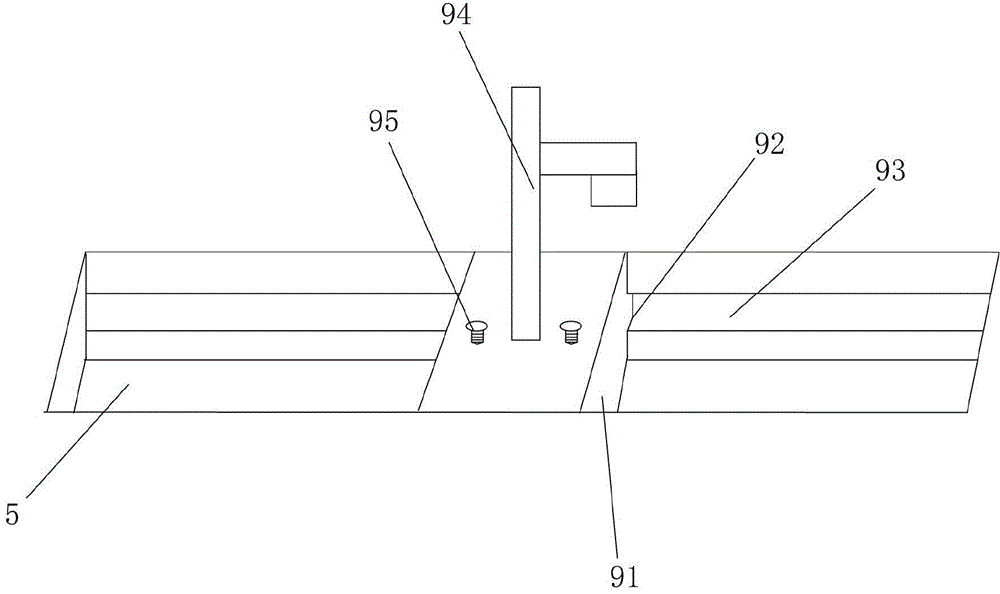

[0019] Such as figure 1 As shown, a cab positioning and assembling equipment includes an operating platform 1 and a rectangular assembling platform 2 whose middle part is vertically sunken to form a rectangle. The assembling platform 2 is provided with horizontal and vertical clamping mechanisms (3, 4) and horizontal and The sliding groove 5 positioned by the longitudinal clamping mechanism (3, 4), the sliding groove 5 extends along the center of the assembly tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com