Compensation method for edge effect of high precision aspheric milling

A technology of edge effect and compensation method, used in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of tool lift, edge collapse and swaying of processed workpiece, and eliminate edge slump or warping. , The effect of good workpiece surface and more reasonable workpiece surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment and accompanying drawing, the present invention is described in detail, present embodiment implements under the premise of technical solution of the present invention, has provided detailed embodiment and specific operation process, but protection scope of the present invention is not limited to Examples described below.

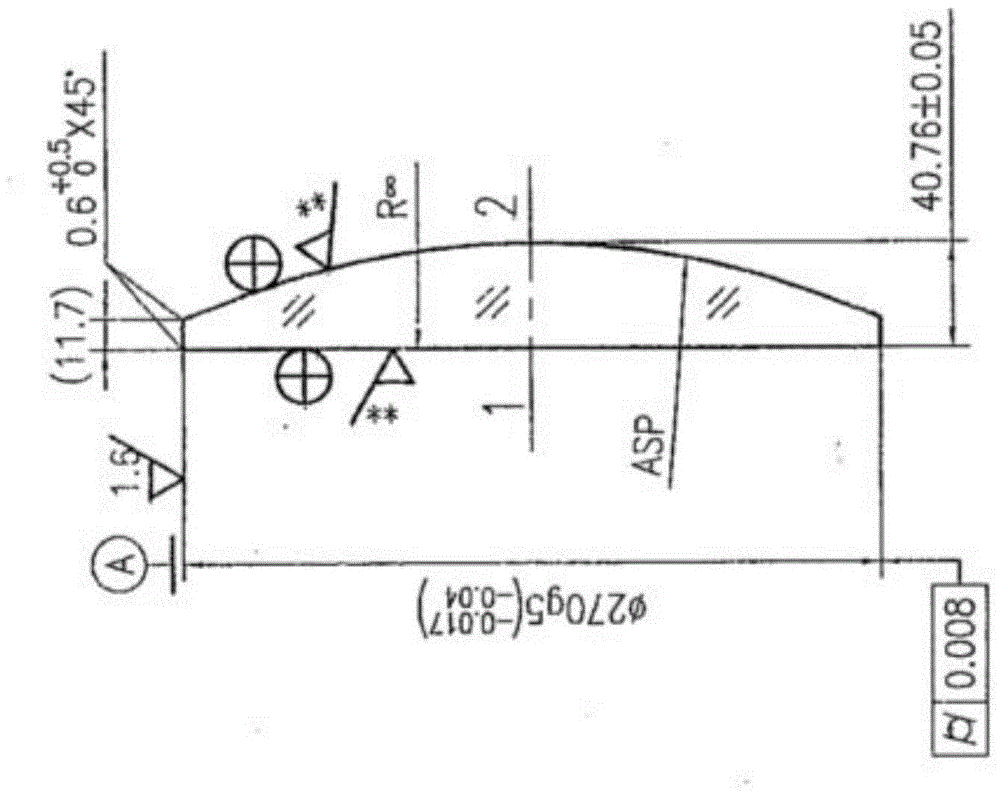

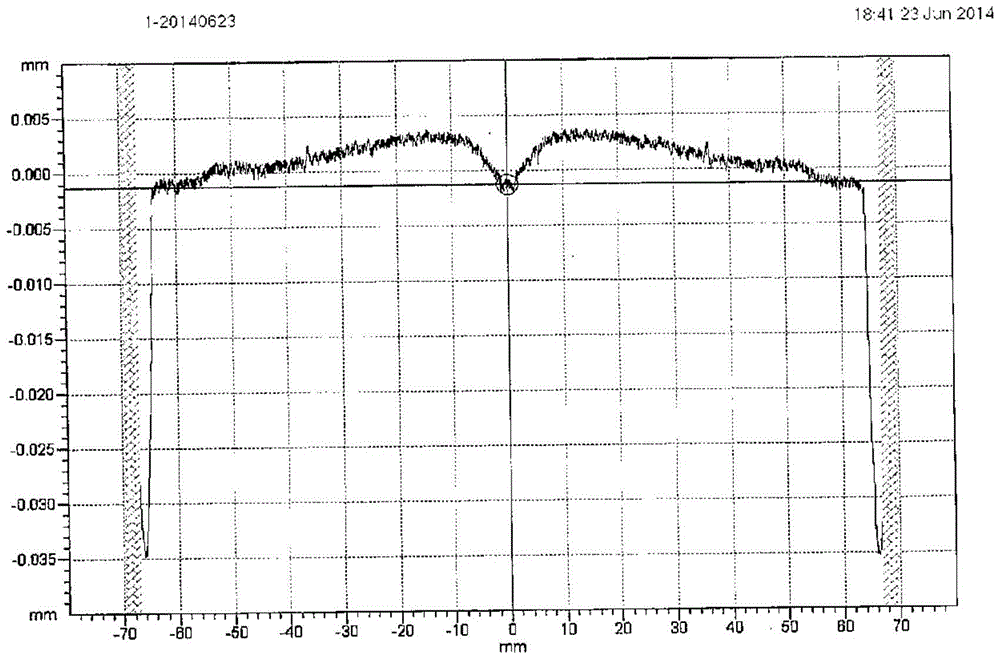

[0027] figure 1 It is an embodiment diagram of an aspherical workpiece to be processed, and the formula of the aspheric surface is as follows:

[0028] Z = c · r 2 1 + 1 - ( 1 + k ) · c 2 · ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com