Automobile redirector rack milling machine

A technology for automobile steering gear and rack milling machine, which is applied in the directions of gear teeth, gear cutters, and components with teeth, etc., can solve the problems of low work efficiency, rough processing quality and high production cost, and achieves simple structure, simple process, Fine quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

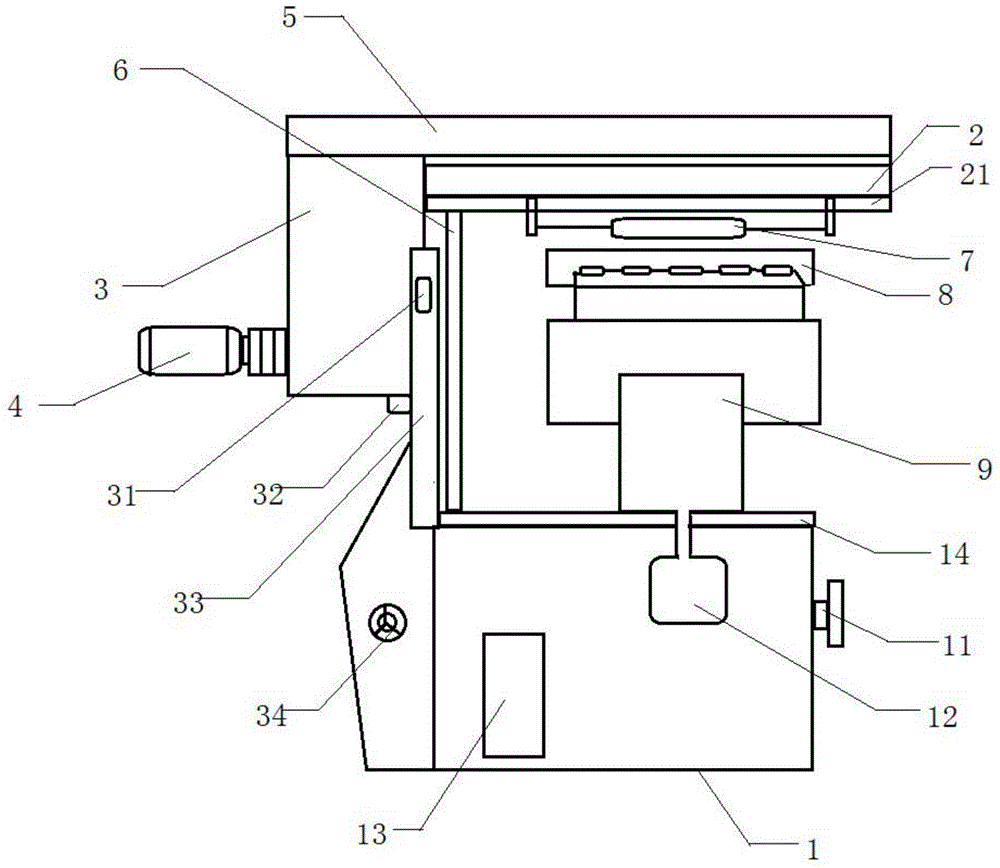

[0012] figure 1 It shows a schematic structural view of an automobile steering gear rack milling machine according to an embodiment of the present invention;

[0013] Such as figure 1 As shown, a car steering gear rack milling machine includes a bed 1 and a workbench 2, and also includes a spindle box 3, a feed motor 4, a suspension beam 5, a back plate 6, a forming rack milling cutter 7 and a fixture 9, and the bed The body 1 includes a longitudinal hand wheel 11, a hydraulic device 13 and a horizontal guide rail 14. Two horizontal guide rails 21 are arranged on the bottom surface of the workbench 2. The horizontal guide rails 21 are connected to the horizontal guide rail 14 through the back plate 6. The hydraulic device 13 is used for clamping The positioning and clamping of the workpiece 8 and the spindle box 3 and the automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com