A manufacturing process of lug alloy parts with lug holes

A manufacturing process and lug technology, which is used in manufacturing tools, metal processing equipment, casting and forming equipment, etc., can solve the problems of inconsistency in the shape of the circumferential surface of the castings, unable to fully guarantee the shape of the circumferential surface, and cracks in the castings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

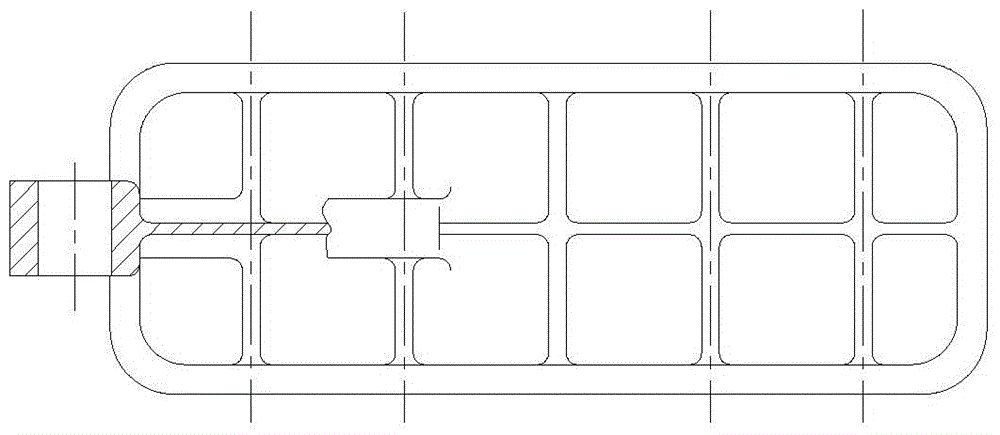

[0022] A manufacturing process of a lug alloy part containing a lug hole provided by the present invention is as follows:

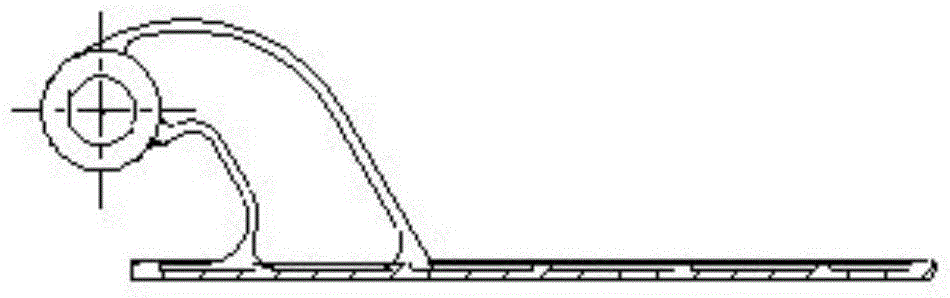

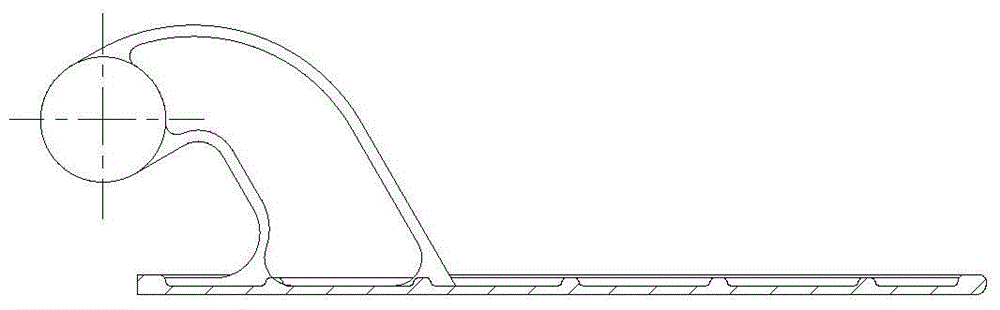

[0023] (1) earlier use wax to make the wax mold of the lug alloy part that contains the lug hole, and make the inner cooling iron with the same size as the lug hole in the wax mold, which is preferred in the present invention, and the material of the inner cooling iron is selected from the same material as the casting

[0024] (2) After the inner cooling iron is inserted into the lug hole, the exposed surface of the inner cooling iron is coated with 0.1-0.2mm thick wax liquid. After the wax liquid solidifies, a 0.1-0.2mm thick wax film is formed on the surface of the inner cooling iron. It is beneficial to the shell making process, the coating and bonding of the shell slurry and sand particles;

[0025] (3) T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com