Process for reducing abrasion of hot-formed steel plate punching punch

A punching and hot forming technology, applied in the field of separation of hot-formed steel plates, can solve the problems of aggravating radial springback and not fundamentally considering radial springback, so as to reduce radial springback and reverse springback. The effect of reducing binding force and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

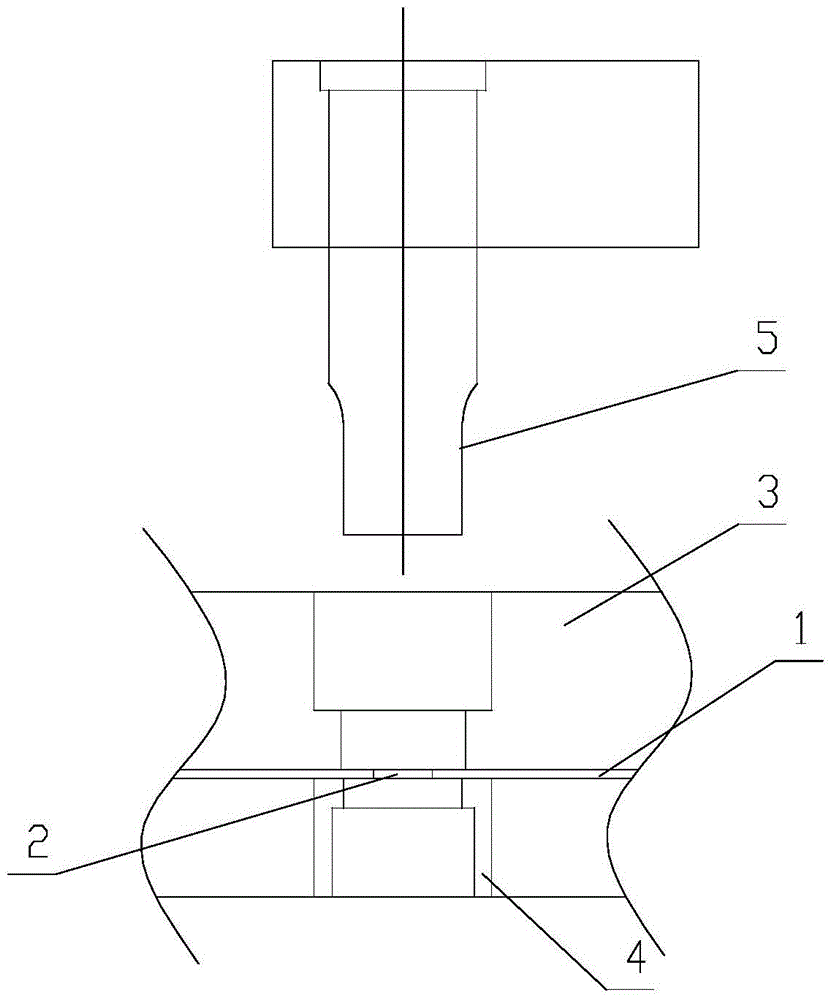

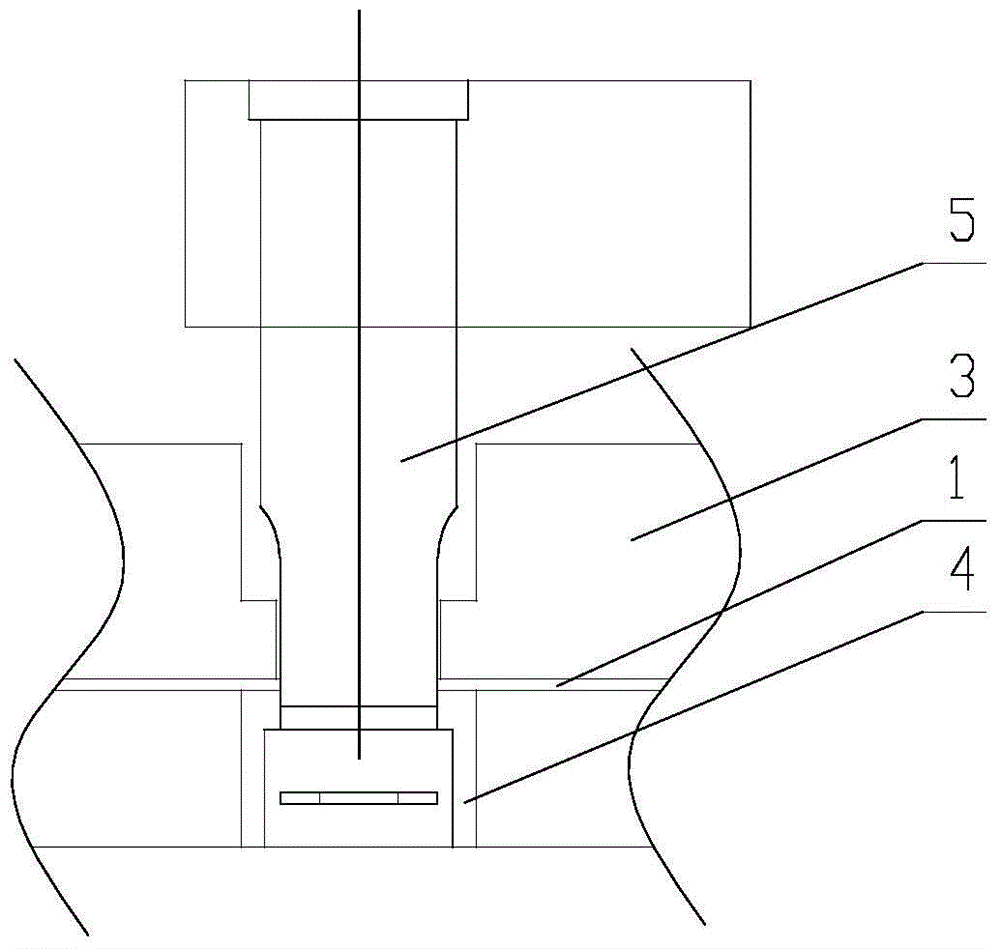

Image

Examples

Embodiment 1

[0022] Embodiment 1: A process for reducing the wear and tear of hot-formed steel plate punching punches, the material of the workpiece: boron steel 22MnB5, thickness 1.6mm, length 400mm, width 200mm, the punched hole is a round hole with a diameter of 10mm;

[0023] The above-mentioned workpieces are specifically processed through the following steps:

[0024] The first step is to perform blanking and pre-punching processing on the workpiece before hot forming. The blanking size is 400×200mm, and the pre-punching hole diameter is 7mm;

[0025] The second step is to hot-form the workpiece;

[0026] The third step is to punch the workpiece according to the final aperture size of the workpiece.

Embodiment 2

[0027] Embodiment two: a kind of technology that reduces the wear and tear of hot-formed steel plate punching punch, workpiece is the B pillar for automobile, material: boron steel 22MnB5, material thickness 1.2mm, length 1250mm, wide 430mm, the punched hole is a round hole, The diameter is 12mm;

[0028] The above-mentioned workpieces are specifically processed through the following steps:

[0029] The first step is to perform blanking and pre-punching processing on the workpiece before hot forming. The blanking size is 400×200mm, and the pre-punching hole diameter is 8mm;

[0030] The second step is to perform thermoforming processing on the workpiece to obtain the B-pillar of the workpiece after thermoforming;

[0031] The third step is to punch the workpiece according to the final aperture size of the workpiece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com