Rotary kitchen waste biochemical treater

A technology of kitchen waste and biochemical processors, applied to mixers with rotating containers, chemical/physical processes, solid waste removal, etc., can solve the problems of high cost and large energy consumption, and achieve better support effects , the effect of rotation stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

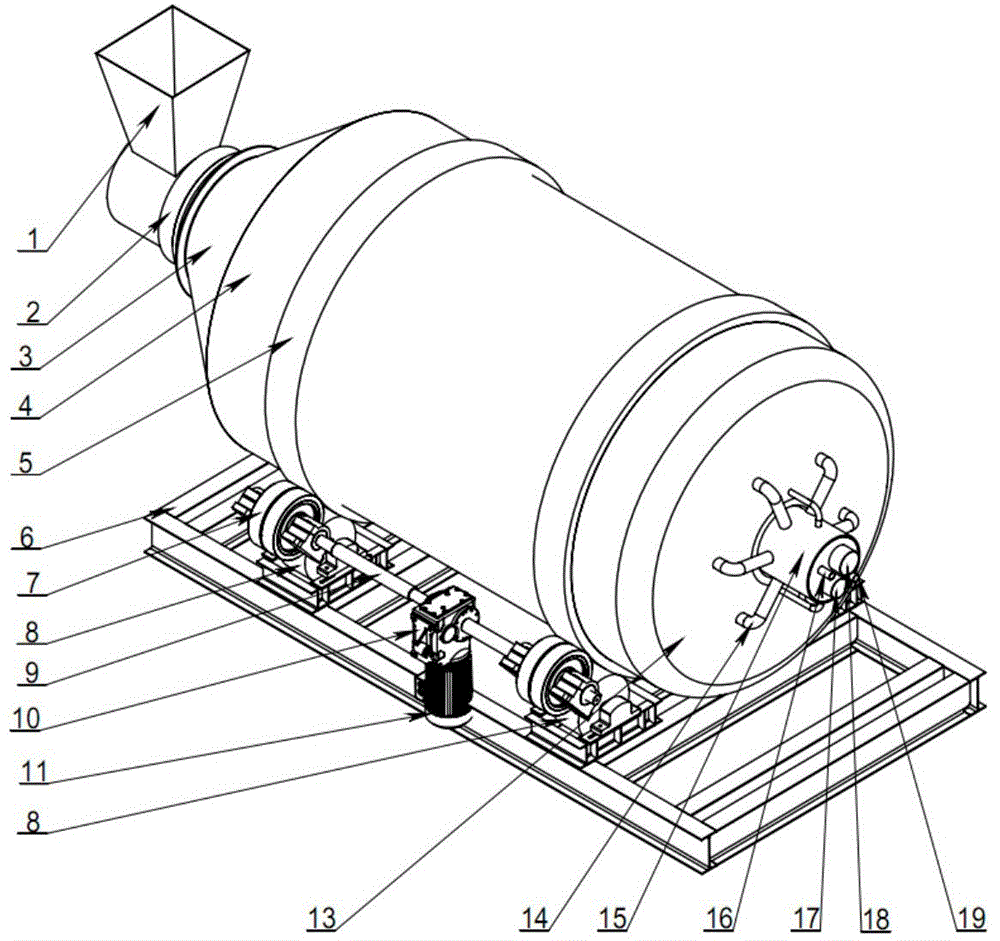

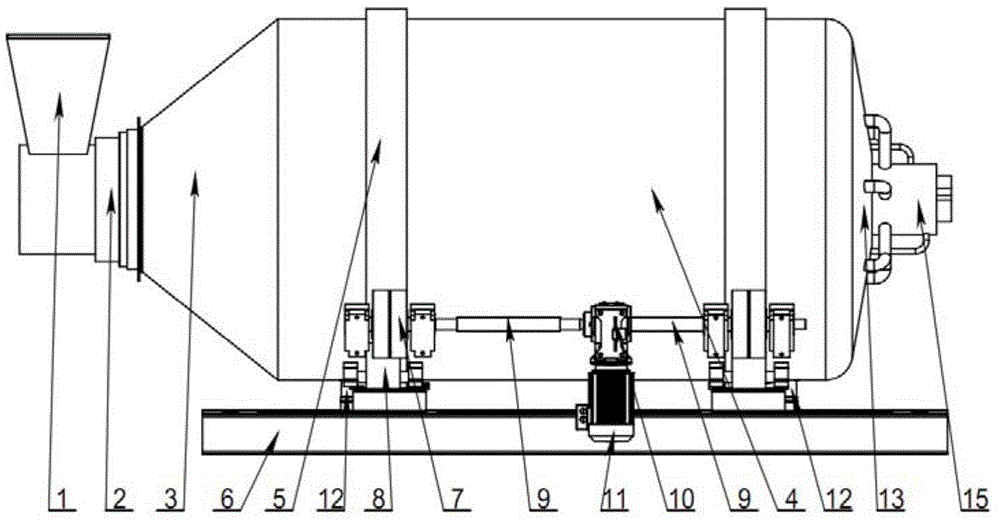

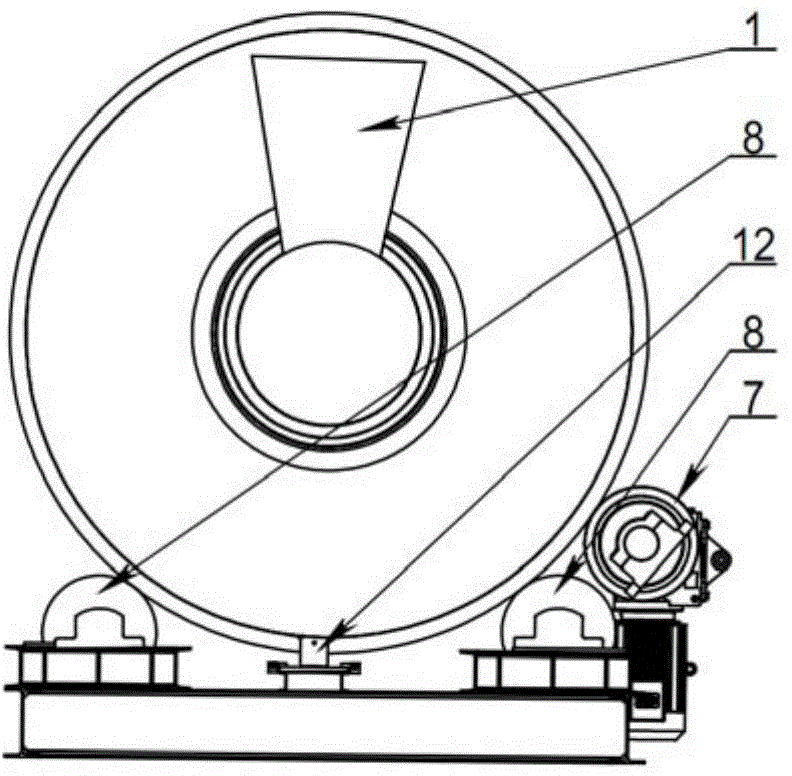

[0028] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0029] See Figure 1 ~ Figure 3 , a rotary biochemical treatment machine for kitchen waste, including a hopper 1, a support 6, a silo, a steam inlet / water pipe 16, a return steam / water pipe 19, an air inlet pipe 18, an exhaust pipe 17, a motor 11, and a reducer 10 and the drive shaft 9, the motor 11 is set on the support 6, the motor 11 is connected with the drive shaft 9 through the reducer 10, the drive shaft 9 is connected with the drive roller 7 installed on the support 6, the drive roller 7 is connected with the The roller table 5 on the outer wall of the silo is circumscribed, and the hopper is located above the support 6, and the support roller 8 circumscribing to the roller table 5 is also installed on the support 6;

[0030] The fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com