Blade type tube cleaner

A pipe pig and blade-type technology, which is applied in the field of blade-type pipe pigs, can solve the problems of large driving force, high energy consumption, and slow cleaning speed, and achieve the effects of light weight, reduced fluid density, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

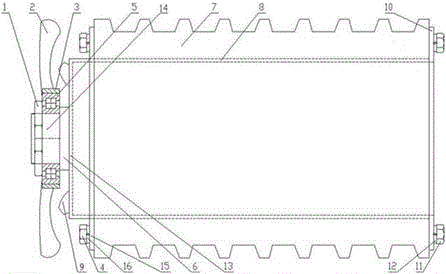

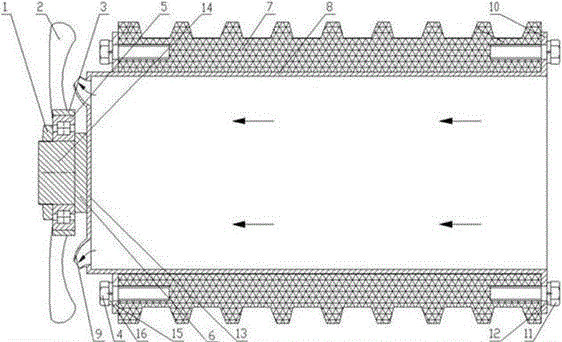

[0029] like figure 1 and figure 2 As shown, the present invention provides a vane type pig, comprising a guide tube 8, the front end of the guide tube 8 is provided with a baffle plate 13, and the center of the baffle plate 13 is positioned on the baffle plate 13 along the axial direction of the guide tube 8. The outer surface of the outer surface is fixedly provided with a central shaft, and the central shaft is provided with blades 2 which can rotate around the central shaft;

[0030] A plurality of nozzles 9 are arranged on the baffle plate 13 , the inner hollow cavity of the guide tube 8 is a fluid channel, the nozzles 9 communicate with the fluid channel, and the rear end of the guide tube 8 is open.

[0031] Put the blade-type pipe pig into the ball barrel at the front end of the effusion pipe. Before putting it in, make sure that the 2 ends of the pipe pig with blades are put in first to complete the delivery work. Under the action of back pressure power, the pig is ...

Embodiment 2

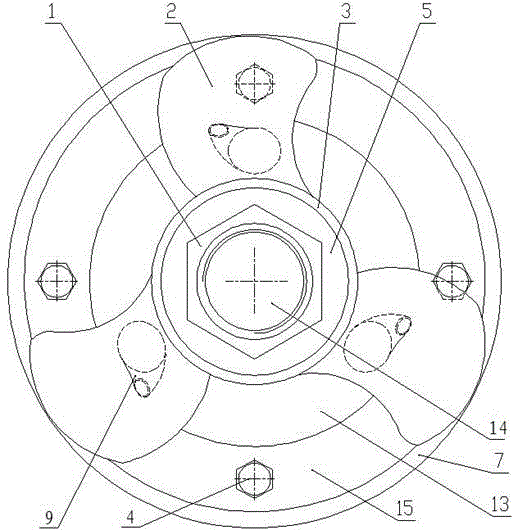

[0033] On the basis of Embodiment 1, specifically, the central shaft is composed of a first central shaft 6 fixedly connected to the center of the baffle plate 13 at one end and a second central shaft 14 connected to the other end of the first central shaft 6. The two central shafts 14 are sheathed with bearings 5 , and the outer circumference of the bearings 5 is provided with blades 2 that can rotate along the bearings 5 . It should be pointed out that the bearing 5 is preferably a cylindrical roller bearing, the second central shaft 14 is inserted into the cylindrical roller bearing through a slight interference fit, and the cylindrical roller bearing is in close contact with the first central shaft 6; the blade 2 can be directly sleeved On the bearing 5, it is also possible to weld the blade 2 on the rotor 3, and then set the rotor 3 on the bearing 5, such as image 3 As shown, the outer periphery of the bearing 5 is covered with the rotor 3 , the cylindrical roller ...

Embodiment 3

[0035] On the basis of embodiment 1 or embodiment 2, such as figure 2 As shown, in order to protect the draft tube 8 , the vane pig also includes a tooth-shaped sealing tube 7 sleeved on the outer periphery of the draft tube 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com