Dispersing method for SiC nanopowder

A kind of powder and nanotechnology, which is applied in the dispersion field of nano-SiC powder, can solve the problem of easy agglomeration of nano-SiC powder, and achieve the effect of not being easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

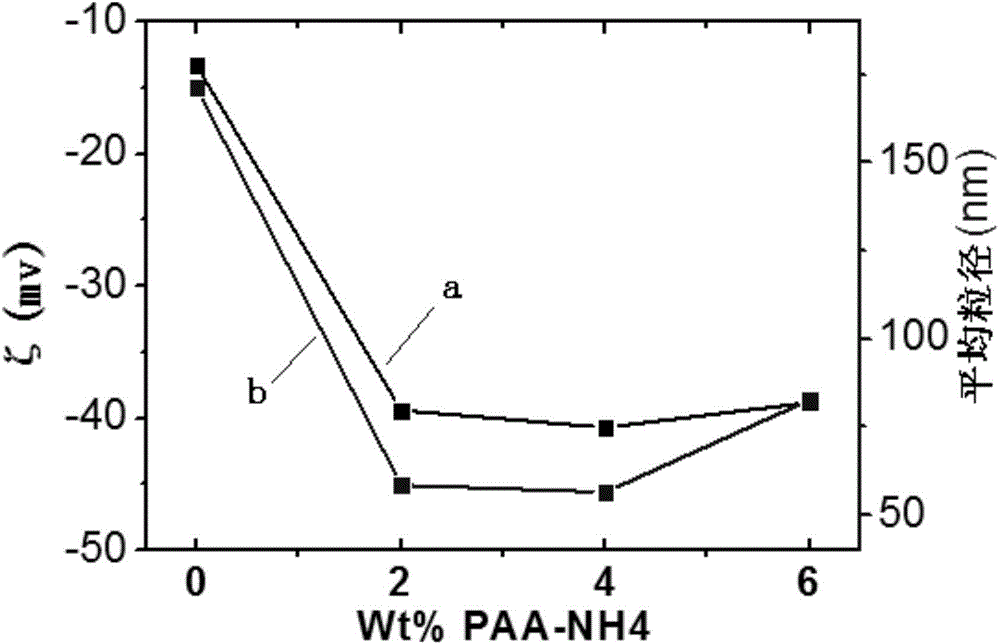

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: the method for dispersing nano-SiC powder in this embodiment is carried out according to the following steps:

[0015] 1. Titrate deionized water with alkali to obtain a solvent with a pH of 12;

[0016] 2. Weigh the SiC powder and the dispersant, add the SiC powder and the dispersant to the solvent successively, and ultrasonicate for 14-16 minutes to obtain a uniformly dispersed slurry, that is, complete the dispersion of the nano-SiC powder.

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the alkali in step 1 is ammonia water. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in Step 2, the particle size of the SiC powder is 50 nm, and the purity is greater than 99%. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com