Preparation method of pinhole-free dedusting filter bag

A production method, a technology without pinholes, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of PM2. Low cost, good use effect and high filtering precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

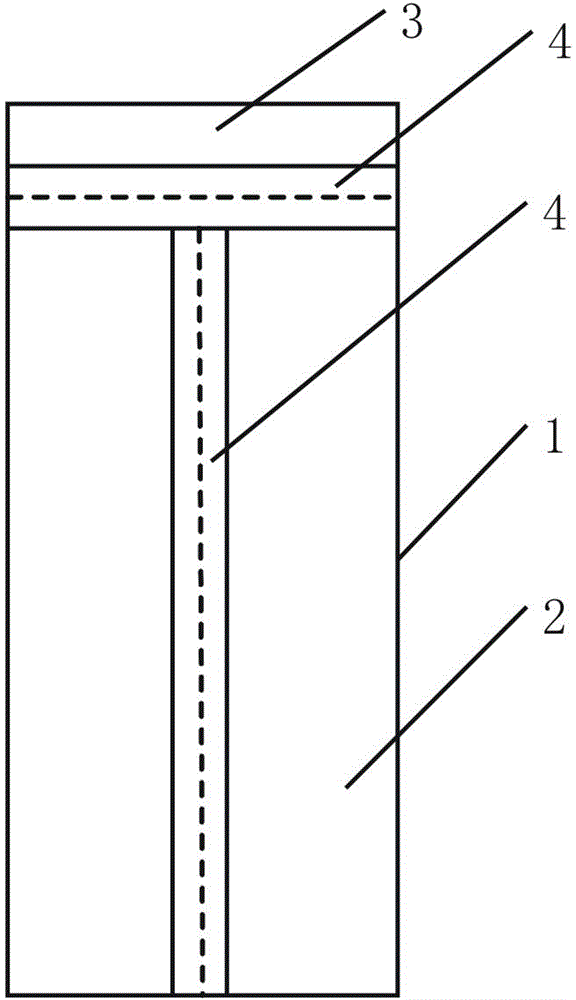

[0014] See attached figure 1 , filter bag 1 of the present invention adopts the polyester spun-bonded non-woven fabric of composite polytetrafluoroethylene microporous film on the dust face to make, and bag body 2 adopts three needles to sew, and bag mouth 3 adopts four needles to sew. On the sewing needle of the filter bag 1, the microporous belt 4 that is single-sidedly sintered and shaped is hot-pressed, and the microporous belt 4 is covered on the needle seams of the sewing bag body 2 and the bag mouth 3, so as to improve the quality of the sewing filter bag 1. The filter accuracy at the needle seam, the specific production is carried out according to the following steps:

[0015] a. Preparation of microporous tape

[0016] The surface of the polytetrafluoroethylene microporous membrane with a three-dimensional fibrous microporous structure is coated with a meltable polytetrafluoroethylene emulsion at a rate of 5g / ㎡. The average pore diameter of the microporous membrane ...

Embodiment 2

[0020] The filter bag 1 of the present invention is made of polyester needle-punched felt compounded with polytetrafluoroethylene microporous film on the dust-facing surface, the bag body 2 is sewn with three needles, and the bag mouth 3 is sewn with four needles. On the sewing needle line of the filter bag 1, the single-sided sintered microporous belt 4 is heat-pressed and composited, and the microporous belt 4 is covered on the needle seams of the sewing bag body 2 and the bag mouth 3 to improve the sewing of the filter bag 1. The filter accuracy at the needle seam, the specific production is carried out according to the following steps:

[0021] a. Preparation of microporous tape

[0022] The surface of the polytetrafluoroethylene microporous membrane with three-dimensional fibrous microporous structure is coated with polytetrafluoroethylene emulsion at 30g / ㎡. The average pore diameter of the microporous membrane is 1.5 microns, the thickness is 40 microns, the strength is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com