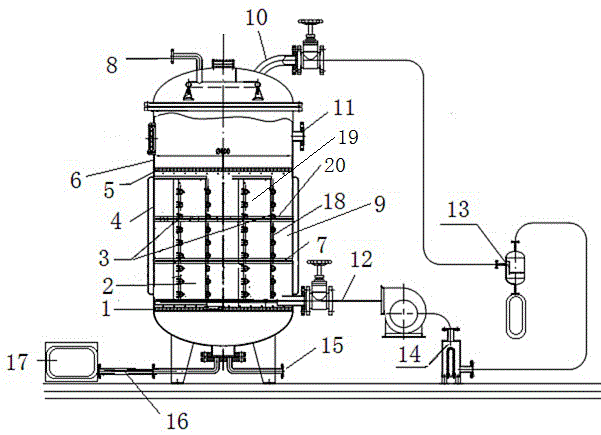

Adsorption device capable of regenerating adsorbent on site and used for transformer oil regeneration

An adsorption device and a technology for transformer oil, which are applied in the fields of solid adsorbent liquid separation, chemical instruments and methods, lubricating compositions, etc., can solve the problems of troublesome operation of adsorbents, secondary pollution, and high cost of regenerating waste power oil. To achieve the effect of convenient and harmless treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The oil pump, the plate-and-frame oil filter, the vacuum oil filter, and the tank body with the oil inlet and the oil outlet are connected to the transformer through the oil pipe. Add nano-copper-loaded activated carbon adsorbent (10 kg, placed in the middle layer of the combined adsorption tank) and XDK-02 type (20 kg, placed on the lower and upper layers of the combined adsorption tank on average) adsorbents in the tank, and introduce the existing degraded Transformer oil (sulfur content 1542.68 mg / l), after heating for 40 minutes, the oil temperature reaches 60°C, and the temperature is constant; then start to filter the oil according to the process of "oil tank-oil processor-oil filter", and oil The flow is basically full of oil, and the pressure of the plate filter is about 0, indicating that the oil filter is flowing smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com