Cashmere goat lamb fattening pellet feed and preparation method thereof

A pellet feed and cashmere goat technology, applied in animal feed, animal feed, applications, etc., can solve the problems of wasting feed resources, polluting the environment, etc., and achieve the effects of reducing production costs, meeting nutritional needs, and good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

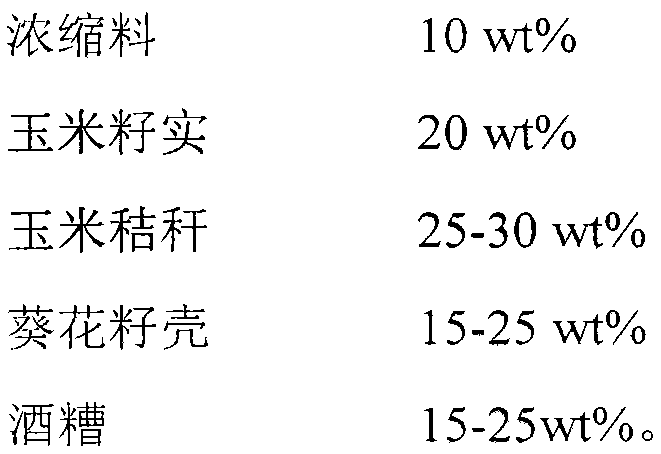

[0037] The raw material ratio of preparation feed is as follows:

[0038]

[0039] Among them, the moisture in the concentrate is ≤14.0, crude protein ≥30.0, crude ash ≤25.0, crude fiber ≤15.0, calcium ≥1.60, total phosphorus ≥0.60, sodium chloride 1.80-5.00, lysine ≥1.00;

[0040] The composition of corn stover includes: 6.48wt% moisture, 3.02wt% crude protein, 2.94wt% crude fat, 41.26wt% phase fiber, 70.83wt% middle-washed fiber, 49.26wt% acid-washed fiber, 47.74wt% lignin and 5.19 wt% ash.

[0041] The composition of corn seeds includes: 11.86wt% moisture, 6.62wt% crude protein, 6.10wt% crude fat, 1.98wt% crude fiber, 14.94wt% medium-washed fiber, 2.43wt% acid-washed fiber, 2.10wt% lignin and 1.60 wt% ash.

[0042] The composition of sunflower seed hulls includes: 7.09wt% moisture, 6.81wt% crude protein, 4.57wt% crude fat, 46.73wt% crude fiber, 68.74wt% middle-washed fiber, 55.04wt% acid-washed fiber, 52.35wt% lignin and 7.87 wt% ash.

[0043] The composition of distil...

Embodiment 2

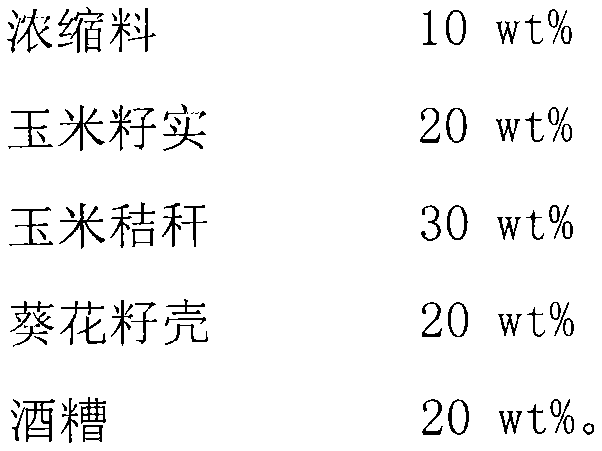

[0051] The raw material ratio of preparation feed is as follows:

[0052]

[0053] Among them, the moisture in the concentrate is ≤14.0, crude protein ≥30.0, crude ash ≤25.0, crude fiber ≤15.0, calcium ≥1.60, total phosphorus ≥0.60, sodium chloride 1.80-5.00, lysine ≥1.00;

[0054] The composition of corn stover includes: 6.48wt% moisture, 3.02wt% crude protein, 2.94wt% crude fat, 41.26wt% crude fiber, 70.83wt% medium-washed fiber, 49.26wt% acid-washed fiber, 47.74wt% lignin and 5.19 wt% ash.

[0055] The composition of corn seeds includes: 11.86wt% moisture, 6.62wt% crude protein, 6.10wt% crude fat, 1.98wt% crude fiber, 14.94wt% medium-washed fiber, 2.43wt% acid-washed fiber, 2.10wt% lignin and 1.60 wt% ash.

[0056] The composition of sunflower seed hulls includes: 7.09wt% moisture, 6.81wt% crude protein, 4.57wt% crude fat, 46.73wt% crude fiber, 68.74wt% middle-washed fiber, 55.04wt% acid-washed fiber, 52.35wt% lignin and 7.87 wt% ash.

[0057] The composition of dist...

Embodiment 3

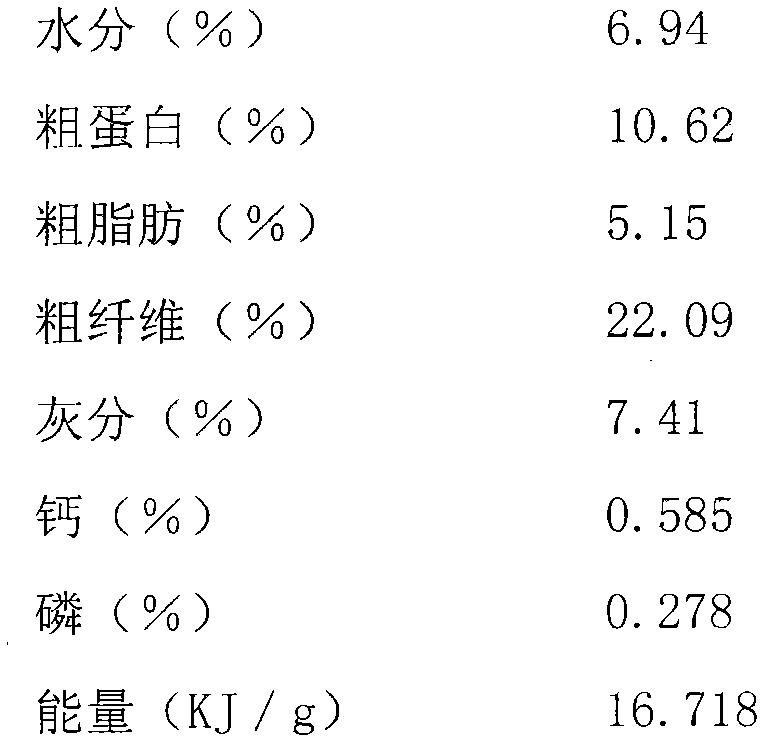

[0065] The raw material ratio of preparation feed is as follows:

[0066]

[0067] Among them, the moisture in the concentrate is ≤14.0, crude protein ≥30.0, crude ash ≤25.0, crude fiber ≤15.0, calcium ≥1.60, total phosphorus ≥0.60, sodium chloride 1.80-5.00, lysine ≥1.00;

[0068] The composition of corn stover includes: 6.48wt% moisture, 3.02wt% crude protein, 2.94wt% crude fat, 41.26wt% crude fiber, 70.83wt% medium-washed fiber, 49.26wt% acid-washed fiber, 47.74wt% lignin and 5.19 wt% ash.

[0069] The composition of corn seeds includes: 11.86wt% moisture, 6.62wt% crude protein, 6.10wt% crude fat, 1.98wt% crude fiber, 14.94wt% medium-washed fiber, 2.43wt% acid-washed fiber, 2.10wt% lignin and 1.60 wt% ash.

[0070] The composition of sunflower seed hulls includes: 7.09wt% moisture, 6.81wt% crude protein, 4.57wt% crude fat, 46.73wt% crude fiber, 68.74wt% middle-washed fiber, 55.04wt% acid-washed fiber, 52.35wt% lignin and 7.87 wt% ash.

[0071] The composition of dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com