Photovoltaic support foundation structure applicable to tidal flat photovoltaic power station and construction method

A photovoltaic support and photovoltaic power station technology, applied in infrastructure engineering, construction, etc., can solve the problems of insufficient pile-soil interaction, difficulty in adapting to the strong corrosive environment of tidal flats, and poor corrosion resistance of spiral steel piles. The effect of earthwork excavation volume, strong durability and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

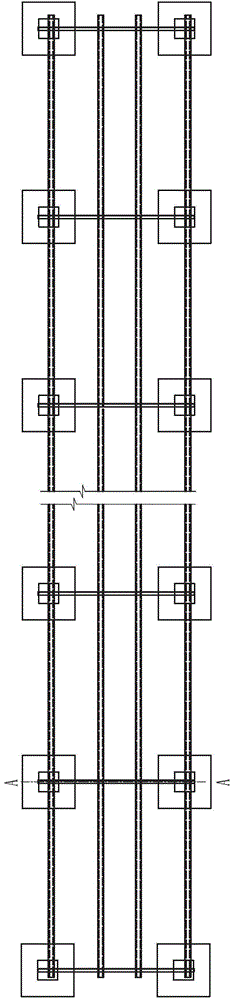

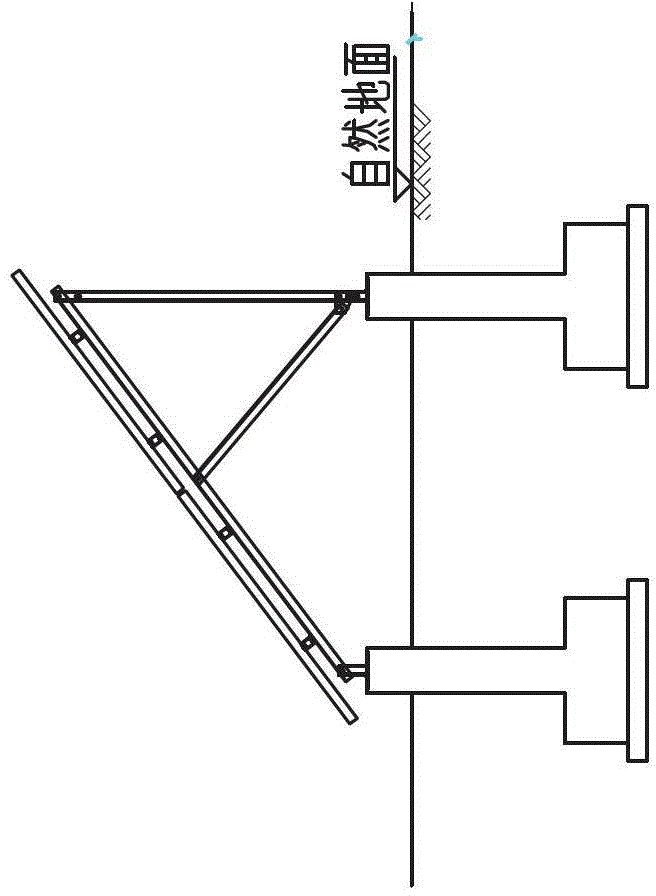

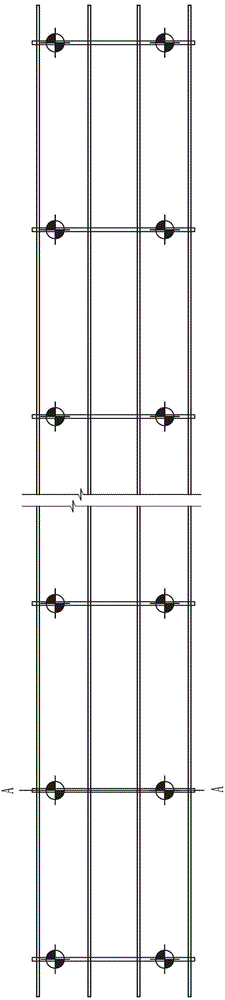

[0022] Such as Figure 3a As shown in and b, the present invention is a photovoltaic support infrastructure suitable for tidal flat photovoltaic power plants, which includes a foundation 1 on the ground, a photovoltaic support 2 is arranged on the foundation 1, and the photovoltaic support 2 includes a front column 21 and a rear column 22. The front and rear columns are respectively set on different foundations, the top of the foundation 1 is pre-embedded with a connector 3, and the photovoltaic support 2 is connected to the foundation 1 through the connector 3; the cross section of the foundation 1 is a rectangle with a side length of 0.2-0.4m Or a circle with a diameter of 0.2-0.4m; the length of the foundation 1 is 2-5m.

[0023] The connector 3 can be a pre-embedded steel plate or a pre-embedded bolt (U-shaped bolt in the figure), which is respectively connected to the front column or the rear column of the photovoltaic support, and the outer surface of the foundation can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com