Method for constructing superhydrophilic antireflection composite coating on glass substrate

A glass substrate and composite coating technology, applied in the field of nanomaterial preparation, can solve the problems of defects, long-term superhydrophilic performance and few reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of sol containing silica particles:

[0038] (1) Mix 22.3mL of tetraethoxysilane, 22.3mL of absolute ethanol, 1.8mL of water and different volumes (5×10 -2 mL, 5×10 -3 mL and 5×10 -4 mL) of concentrated hydrochloric acid (37% by mass fraction) were mixed in a double-neck flask, stirred at a temperature of 60°C for 90 minutes, and then cooled to room temperature to obtain three mixed solutions;

[0039] (2) Add the concentrated hydrochloric acid (mass fraction is 37%) of 7.2mL, the water of 0.4mL and the ethanol of 46.6mL respectively in three kinds of mixed solutions of room temperature that step (1) obtains, after stirring at room temperature for 15 minutes, Aging was carried out at a temperature of 50°C for 3 hours; cetyltrimethylammonium bromide was added to the three aged solutions to make the three aged solutions of cetyltrimethylammonium bromide The mass fraction in all is 2.5%, stir at room temperature for 1 hour, prepare the sol solution containin...

Embodiment 2

[0042] Preparation of sol containing silica particles:

[0043] (1) Mix 22.3mL of tetraethoxysilane, 22.3mL of absolute ethanol, 1.8mL of water and 5×10 -3 mL of concentrated hydrochloric acid (37% by mass) was mixed in a double-neck flask, stirred at 60°C for 90 minutes, and then cooled to room temperature to obtain a mixed solution;

[0044] (2) Add a certain volume (5mL, 7.2mL or 10mL) of concentrated hydrochloric acid (mass fraction is 37%), 0.4mL of water and 46.6mL of ethanol to the mixed solution at room temperature obtained in step (1). Stir for 15 minutes, then carry out aging at a temperature of 50°C for 3 hours; add cetyltrimethylammonium bromide to the aged solution to make the cetyltrimethylammonium bromide in the aged solution The mass fraction in is 2.5%, and stirred at room temperature for 1 hour to prepare a sol solution containing silica particles for preparing a coating.

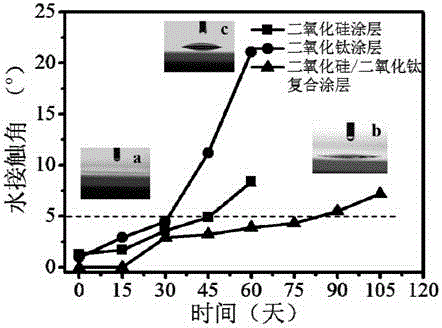

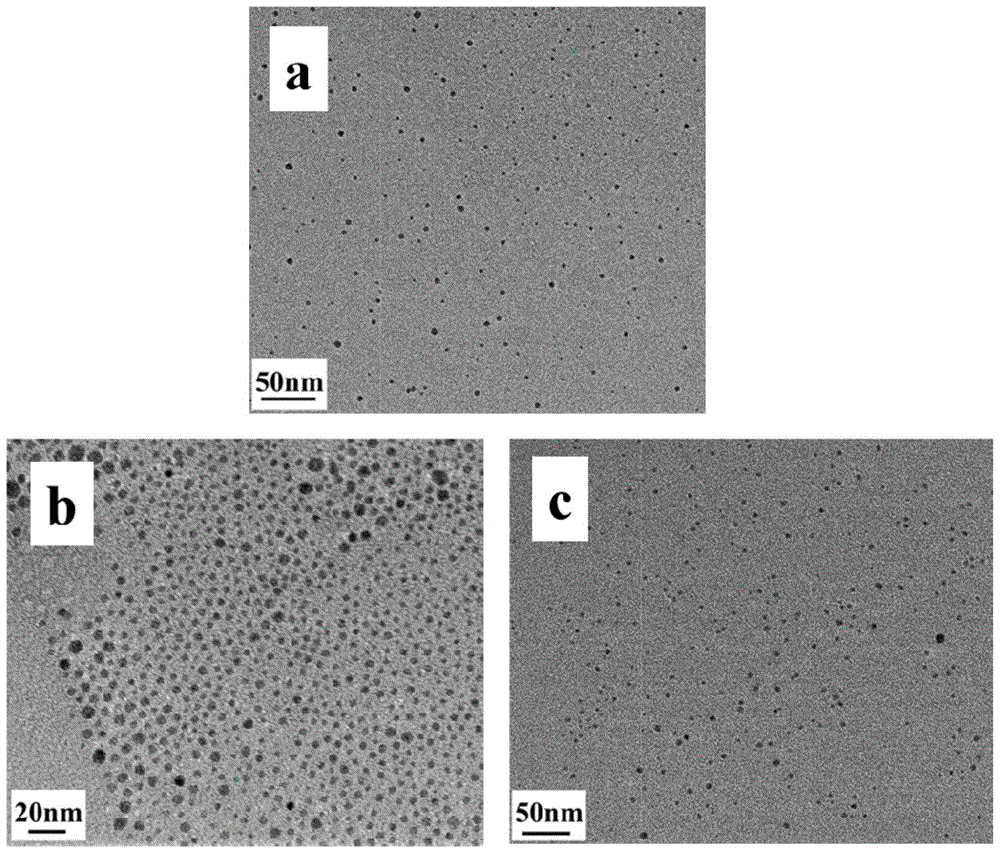

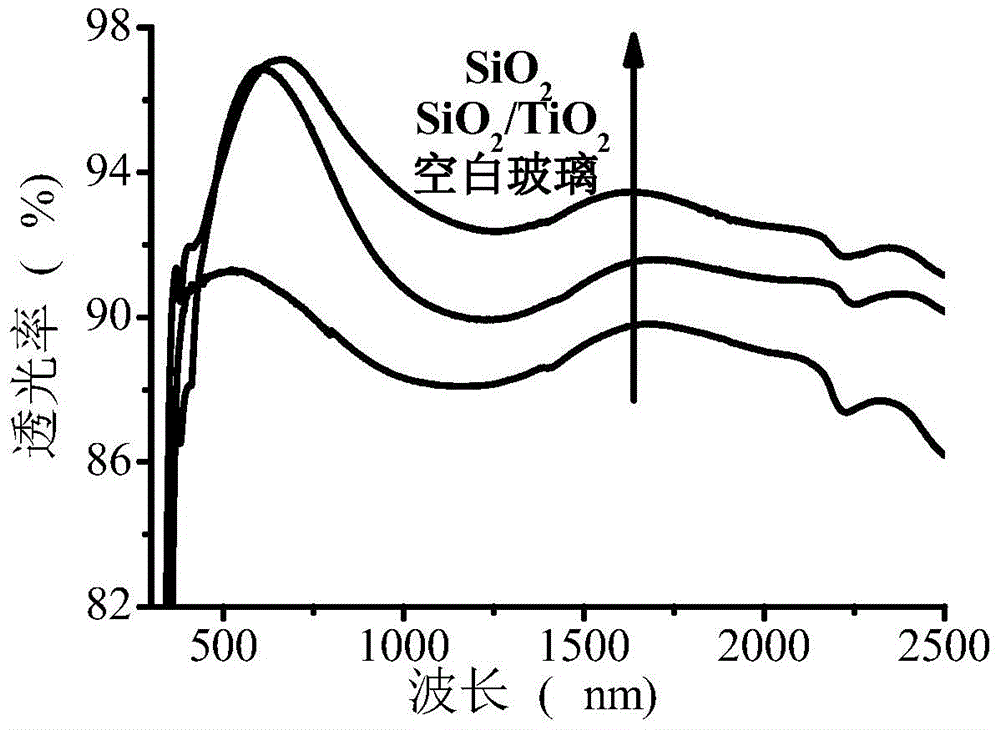

[0045] The characterization of the transmission electron microscope shows that the a...

Embodiment 3

[0047] Preparation of sol containing silica particles:

[0048] (1) Mix 22.3mL of tetraethoxysilane, 22.3mL of absolute ethanol, 1.8mL of water and 5×10 -3 mL of concentrated hydrochloric acid (mass fraction 37%) was mixed in a double-neck flask, stirred at 30°C, 60°C and 90°C for 90 minutes, and then cooled to room temperature to obtain three mixtures;

[0049] (2) Add 7.2mL of concentrated hydrochloric acid (37% by mass fraction), 0.4mL of water and 46.6mL of ethanol to the three mixed solutions at room temperature obtained in step (1) respectively, stir at room temperature for 15 minutes, and then Aging was carried out at a temperature of 50°C for 3 hours; cetyltrimethylammonium bromide was added to the three aging solutions to make the mass of cetyltrimethylammonium bromide in the aged solution The fractions were 2.5%, respectively, and stirred at room temperature for 1 hour to prepare sol solutions containing silica particles for coating preparation.

[0050] The charac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com