Steel rail milling and grinding machine operation accuracy real-time detecting device

A technology for rail milling and grinding vehicles, precision, applied in transportation and packaging, railway car body parts, railway vehicle shape measuring instruments, etc., can solve the problems of high labor intensity and low efficiency, and achieve reduced labor intensity, fast operation accuracy, The effect of improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

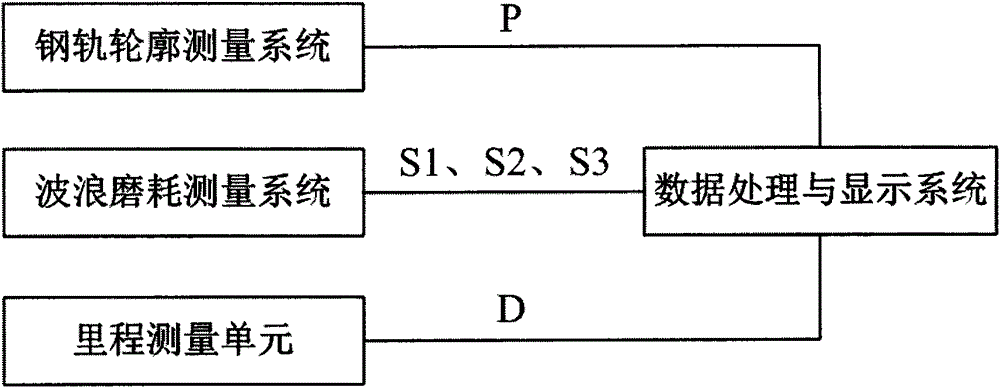

[0014] like figure 1 As shown, the rail profile measurement system 5, the wave wear measurement system 6, and the mileage measurement unit 4 of the present invention are respectively connected with the data processing and display system 7.

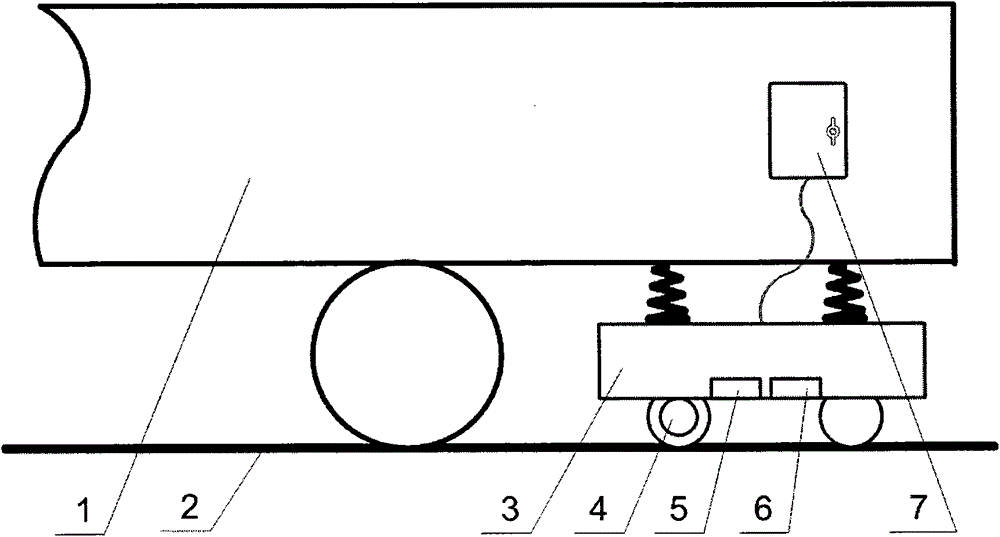

[0015] like figure 2 As shown, the detection device 1 of the present invention is fixed on the bottom beam of the rail milling and grinding vehicle, and the rail profile measurement system 5, the wave wear measurement system 4, and the mileage measurement unit 4 are respectively installed on the detection device 3.

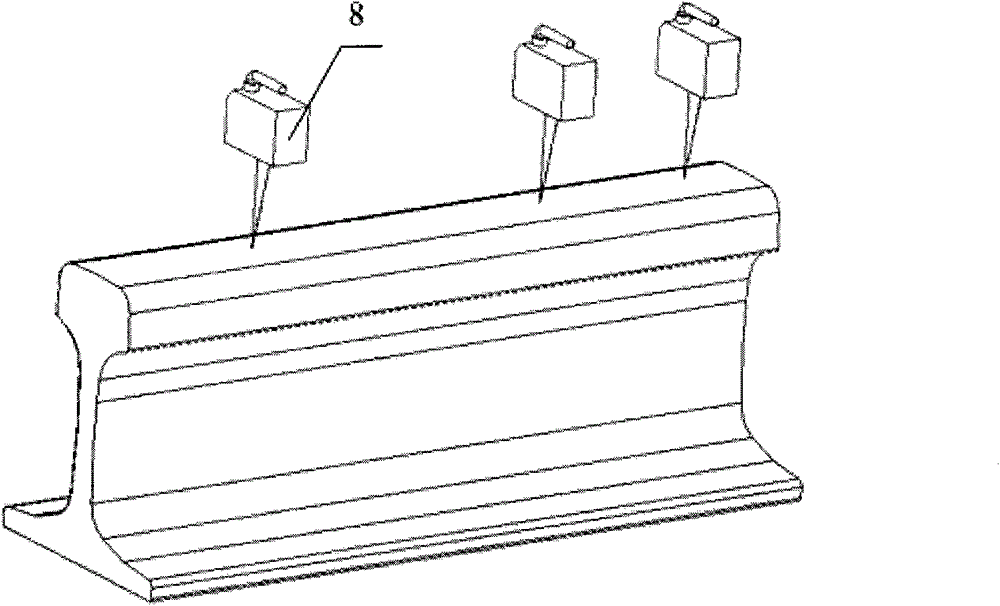

[0016] like image 3 As shown, the wave wear measurement system 6 of the present invention is made up of three high-precision non-contact displacement sensors 8.

[0017] like Figure 4 As shown, the rail profile measurement system 5 of the present invention consists of a laser 9 and an industrial camera 10 .

[0018] In the detection device provided by the present invention, before the milling vehicle 1 starts working, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com