Device for polishing rear angle of combined drill bit cutter

A technology of cutter back angle and combined drill bit, which is applied in the direction of drilling tool accessories, drilling/drilling equipment, boring machine/drilling machine parts, etc., to improve grinding efficiency, ensure accuracy and consistency, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

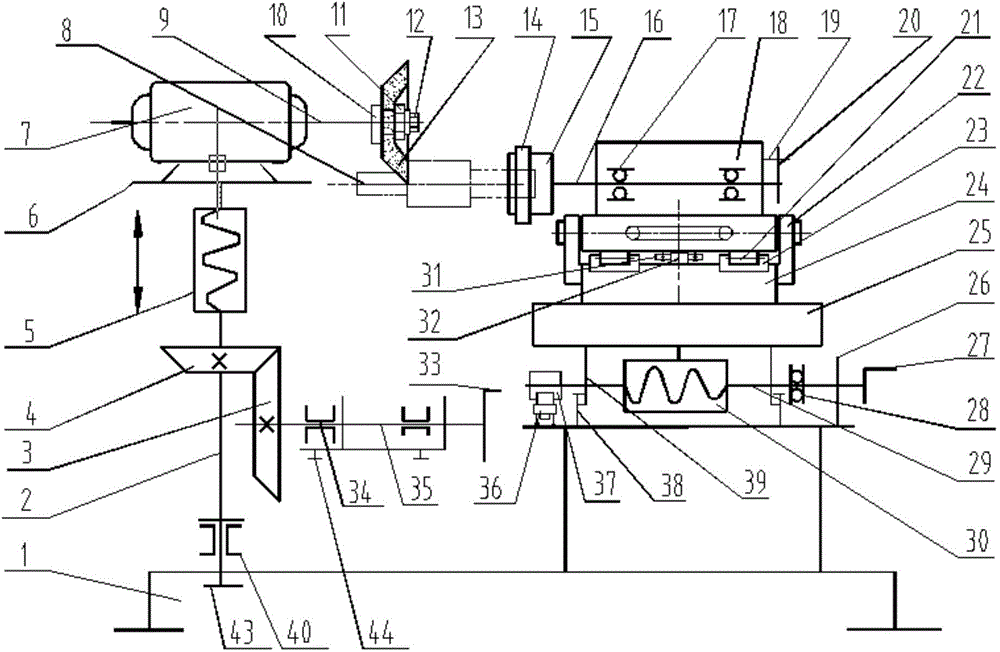

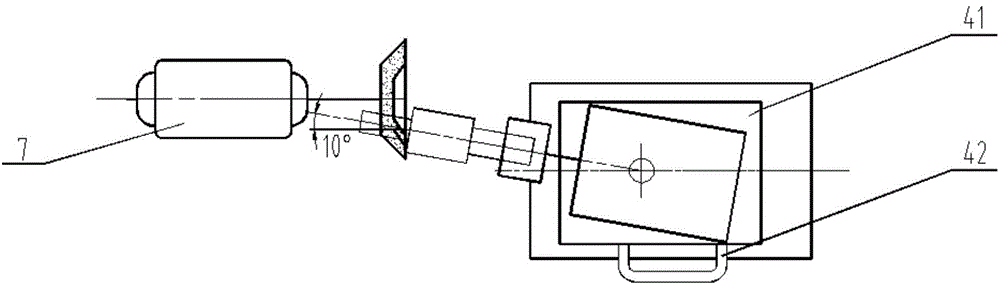

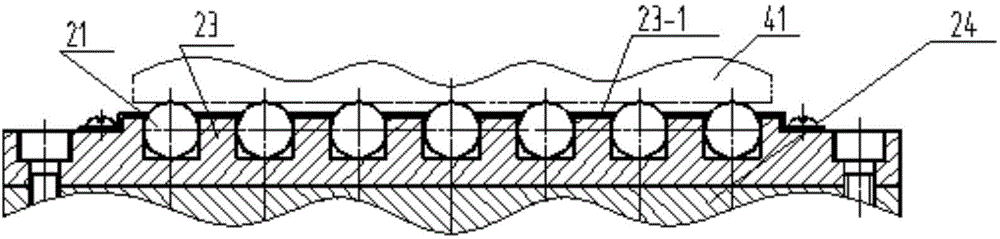

[0027] The present invention comprises: motor 7, shaft 16, shaft 16 is fixedly installed on the machine base 18 through bearing 17, one end of shaft 16 is equipped with elastic jacket 15 and lock nut 14, the inner hole of jacket 15 is connected with the hole of tool 8 to be ground The knife handle is equipped, and the other end is fixedly installed with an indexing plate 20. The indexing plate is provided with an indexing hole, and the latch 19 is inserted into the positioning hole of the machine base 18 through the indexing hole of the indexing plate; the output shaft 9 of the motor 7 is mounted on the There is a grinding wheel installation sleeve 10, which is fixed on the output shaft 9 through a nut 12, and the grinding wheel 13 is fixed on the installation sleeve 10 through a clamping nut 11; the shaft 16 is fixedly connected with the inner sleeve of the bearing 17, and the outer ring of the bearing is fixed on the machine base 18, the shaft 16 can be rotated to solve the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com