Fruit and vegetable drying machine

A drying machine, fruit and vegetable technology, applied in the fields of application, food processing, food science, etc., can solve the problems of high processing cost, strong shaking of the drying barrel, complex structure, etc., and achieve the effect of reducing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

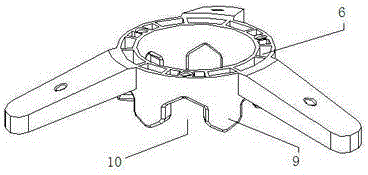

[0023] As shown in the figure, the spin-drying bucket and the base are engaged by a clamping module, and the clamping module is divided into upper and lower parts. The upper clamping module fixed on the base is the lower clamping module fixed on the bottom of the spin-drying bucket. Snap module. The upper clamping module and the lower clamping module are equipped with equal slotting teeth and card slots, and the slotting teeth and card slots are evenly arranged. The space between the slotting teeth forms the card slot. The drying barrel is connected to the output shaft of the motor through a locking module. The locking module is divided into an upper locking slot module and a lower locking slot module. , the output shaft of the motor is connected with the drying bucket; a plurality of drainage holes are arranged on the surface of the drying bucket to remove the dried water; a drain pipe is connected with the bottom of the shell 1 to discharge the dried water.

[0024]

Embodiment 2

[0026] Referring to the figure, except for the same parts as in Example 1, the spin-drying bucket and the base are engaged by a snap-in module, which is divided into upper and lower parts, and the upper snap-in module fixed on the base is fixed on the spin-dryer The bottom of the bucket is the lower snap module. The upper clamping module and the lower clamping module are equipped with equal slotting teeth and card slots, and the slotting teeth and card slots are evenly arranged. The space between the slotting teeth forms the card slot. The slots match the size of the slots, and the space between the adjacent slots forms five or six slots accordingly. The slots of the lower engaging module are the same size as the slots of the upper engaging module. Install the drying barrel After the lower engaging module drops to a proper position and contacts the upper engaging module, if the pinion of the lower engaging module touches the pinion of the upper engaging module, the pinion of ...

Embodiment 3

[0034] In addition to the same parts as in Embodiment 2, in order to better prevent the shaking of the spin-drying bucket when it rotates, the upper engaging module is also provided with a support protruding from the center, and the bottom of the spin-drying bucket is provided with a support When installing the drying bucket, you only need to align the bottom hole with the support protruding from the upper clamping module. The support can also play a guiding role, making the clamping position of the card and the module more accurate. Because the supporting member is coaxially fixed with the output shaft of the motor and has a certain height, it can prevent the shaking of the spin-drying bucket when it rotates.

[0035]

[0036] As the height of the support increases, its effect on preventing the shaking generated when the spin-drying bucket rotates is greater, but after many tests, it is found that the height of the support extending into the spin-drying bucket is equivalent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com