Inclined shaft heading machine

A technology for roadheaders and inclined shafts, which can be used in mining equipment, earthwork drilling, tunnels, etc. It can solve the problems of difficult installation of steel arch frames at the bottom of tunnels, and achieve the effect of improving splicing efficiency and shortening distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

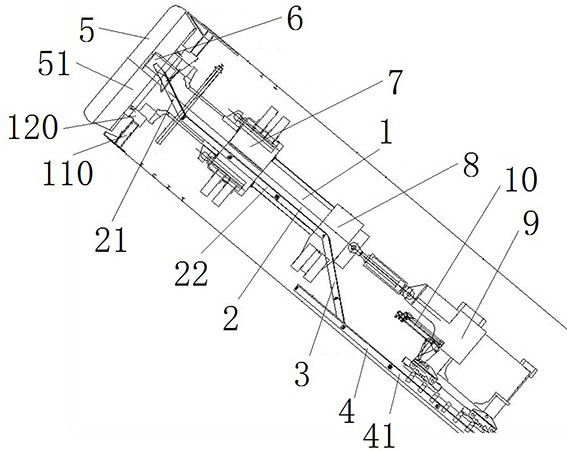

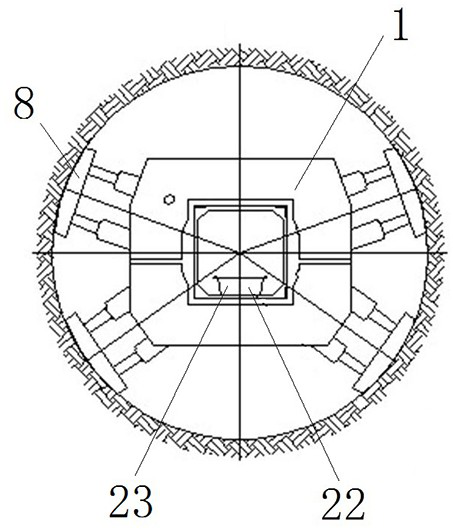

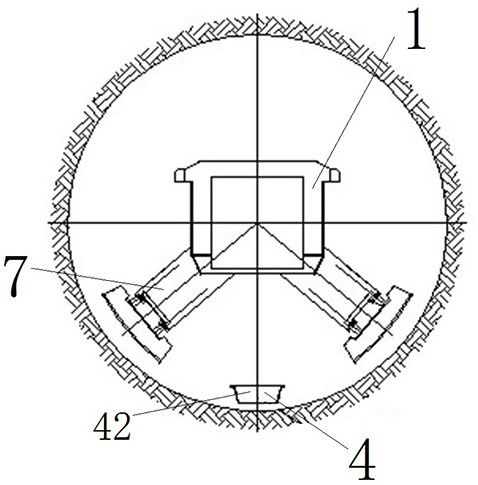

[0036] Such as figure 1 As shown, the inclined shaft boring machine includes a main beam 1, which extends along the direction of the inclined shaft tunnel. The front end of the main beam 1 is connected to the cutter head 5 through the cutter head flange 120, and the cutter head 5 is provided with a muck bin 51. The rear side of the muck bin 51 is provided with a slag collecting tank 6, which is connected with the main beam 1 for collecting the muck in the muck bin 51; The inclined shaft boring machine moves forward along the axial direction of the tunnel; the rear support 8 is installed at the end of the main beam 1 for supporting the main beam 1 when the stay shoe 7 is retracted; the main drive 110 and the slide are also installed on the main beam 1 For the slag parts, the main drive 110 drives the cutter head 5 to move, and the slag sliding parts are connected with the slag collecting tank 6;

[0037] Main girder 1, cutter head 5, support shoe 7, rear support 8 and anti-rol...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the central slag slider 2 is fixedly connected to the transfer slag slider 3 . And in the present embodiment, the transfer slag sliding part is swingably connected with the central slag sliding part.

Embodiment 3

[0049] The difference between this embodiment and Embodiment 1 lies in that in Embodiment 1, the slag slag runner has a groove-like structure as a whole. In the present embodiment, the center slag chute and the transfer slag chute in the slag chute are tubular structures, and the ends of the tubular transfer slag chute extend into the bottom slag chute of the bottom slag chute.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com