Brushless AC smoke ventilator motor

An electromechanical and oil fume technology, applied in the direction of electromechanical devices, electrical components, single motor speed/torque control, etc., can solve the problems that cannot be popularized and applied in large quantities, high manufacturing costs, etc., and achieve small vibration, low cost, and smooth start-up operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

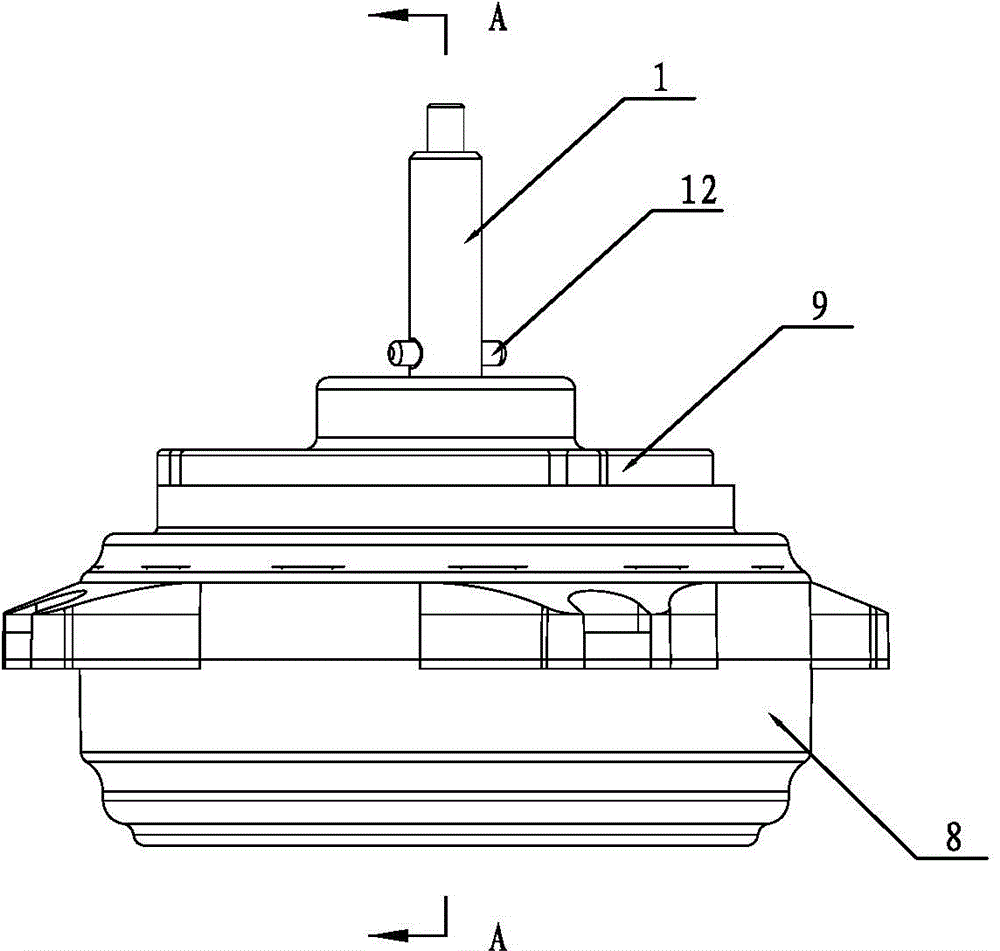

[0023] Such as Figure 1-3 As shown, a brushless AC range hood motor includes a rotor, a stator, a casing and a control circuit for driving the motor, wherein the rotor includes a rotor core 2, and a rotating shaft 1 arranged in the middle of the rotor core 2 is in close contact with The magnetic steel 3 on the outer ring of the rotor iron core 2, and the plastic cage 4 sleeved on the outer ring of the magnetic steel 3, the rotor iron core 2 is an AC brushless permanent magnet rotor iron core; the stator includes a stator iron core 5 and an insulating plastic sheath 6, wherein the insulating plastic sheath 6 is coated on each tooth of the stator iron core 5, and each tooth of the stator iron core 5 coated with the insulating plastic sheath is wound with an enameled wire 7 to form a motor coil (i.e. Stator winding); the housing includes a plastic-encapsulated main body 8 and an end cover 9 mounted on the plastic-enclosed main body 8, bearings are provided at both ends of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com