Novel gyro motor

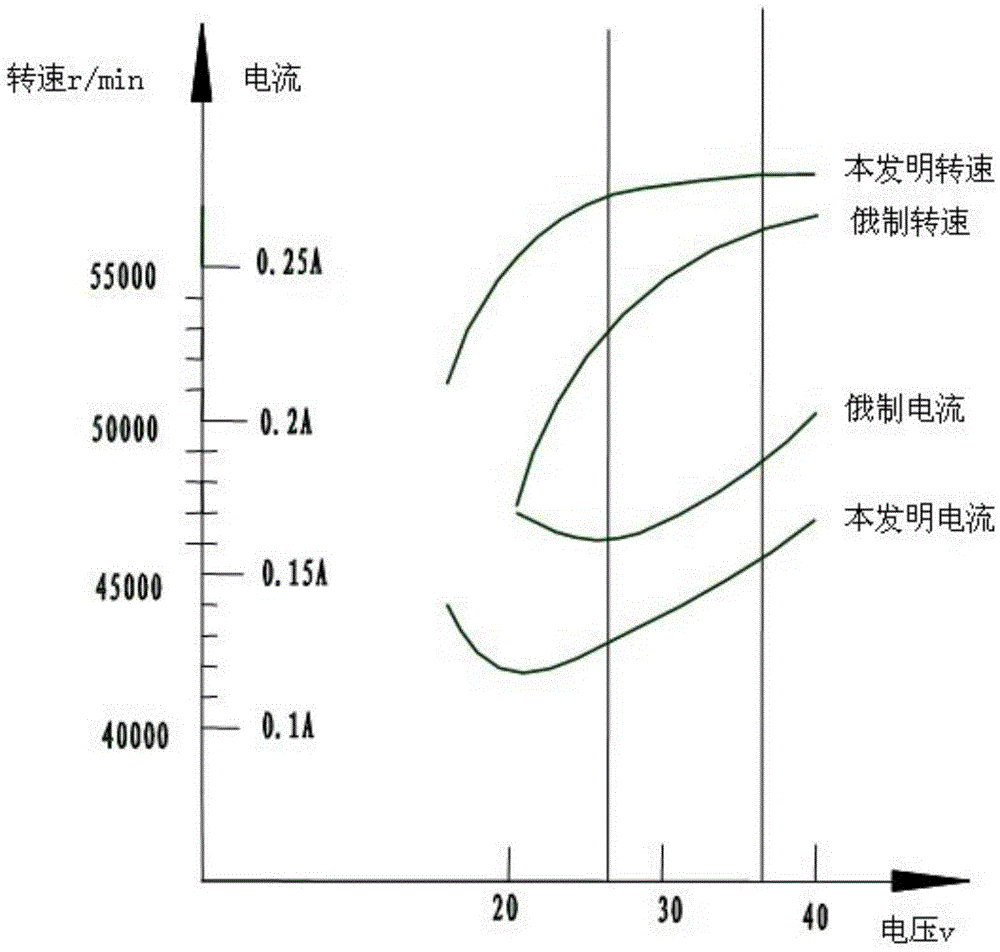

A gyro, a new type of technology, applied in electrical components, electromechanical devices, magnetic circuit rotating parts, etc., can solve the problems of low efficiency, low reliability, and many failures of gyro motors, reduce gyro drift error, and improve working life. , The effect of motor performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

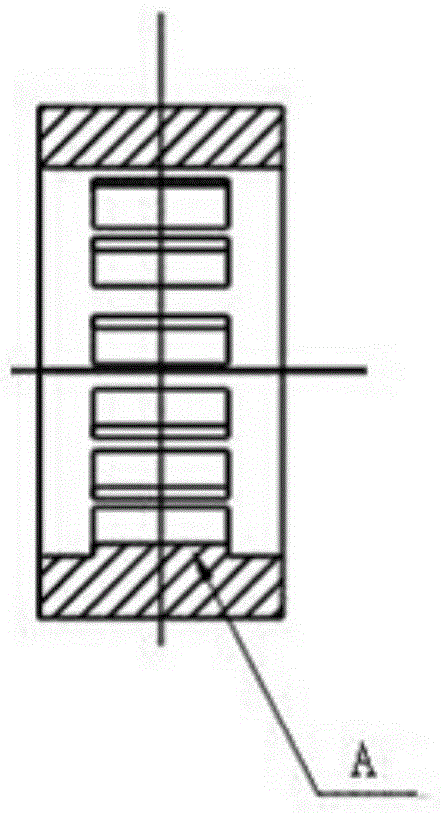

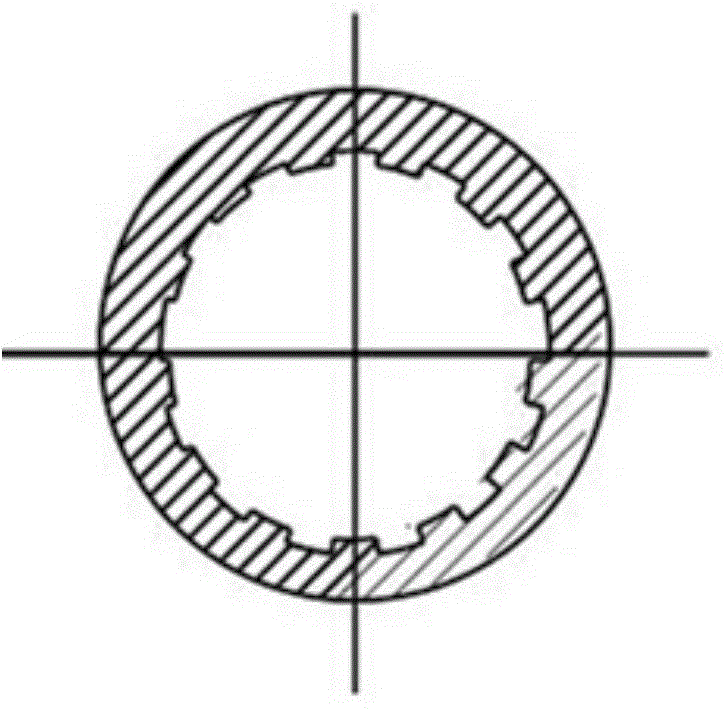

[0022] like Figure 3-4 , 7-10, the rotor core of the novel gyro motor of the present invention is made of an integral and cheap soft magnetic material, the notch portion of the groove for embedding the squirrel cage guide bar is narrow and the inside of the groove is wide and Deep, which reduces the magnetic conduction area occupied by the notch, and enables the slot to accommodate a sufficiently large conductive cross-sectional area. The guide bar of the squirrel cage made of pure copper is narrow, and can enter into the wider slot through the narrower iron core notch mentioned above, but the length of the squirrel cage guide bar is greater than the length of the iron core, so as to compress the length and make the guide bar The thick section becomes larger, filling the iron core groove to form a firm embedded state. The part of the rotor core corresponding to the squirrel cage end ring has an annular groove that can accommodate part of the squirrel cage end ring, so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com