Cable pre-cutting process method

A process method and pre-cutting technology, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of high protection difficulty, large cable total amount, and high cable cost, so as to reduce the total amount of handling and reduce the difficulty of protection , The effect of convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to overcome the problem that the total amount of cables involved in the cable cutting process in the prior art is large, the protection is difficult, and the cost of cable cutting is high, the present invention compiles the cable booklet with the information of the pre-cut cables, and then analyzes the cable booklet The data is used to cut the cables, and finally the cut cables are arranged and rolled into the cable barrel according to the analysis data, which greatly reduces the production cost.

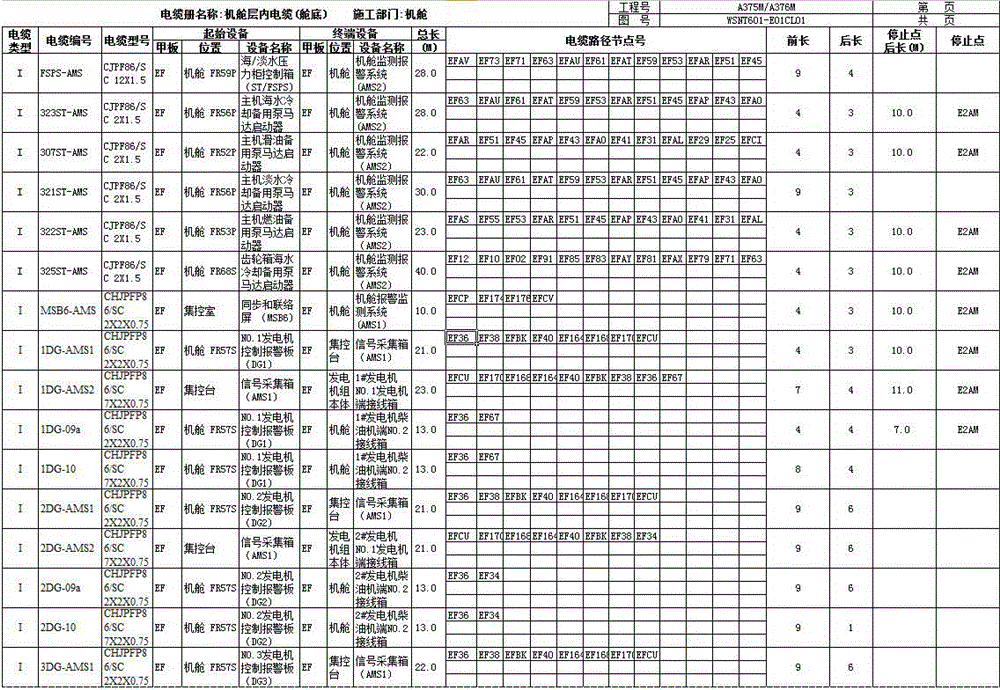

[0035] In the process of compiling the cable book, the summarized content includes: the pages of cables in each area and bus cables, the statistical length of cables of various specifications in the whole ship, the total length of the cable book and other relevant information. The contents of the cable booklet include the following items:

[0036] a) serial number;

[0037] b) Cable category, for example: high voltage, low voltage, control / communication, intrinsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com