Calibration plate and a thermal infrared camera calibration method based on same

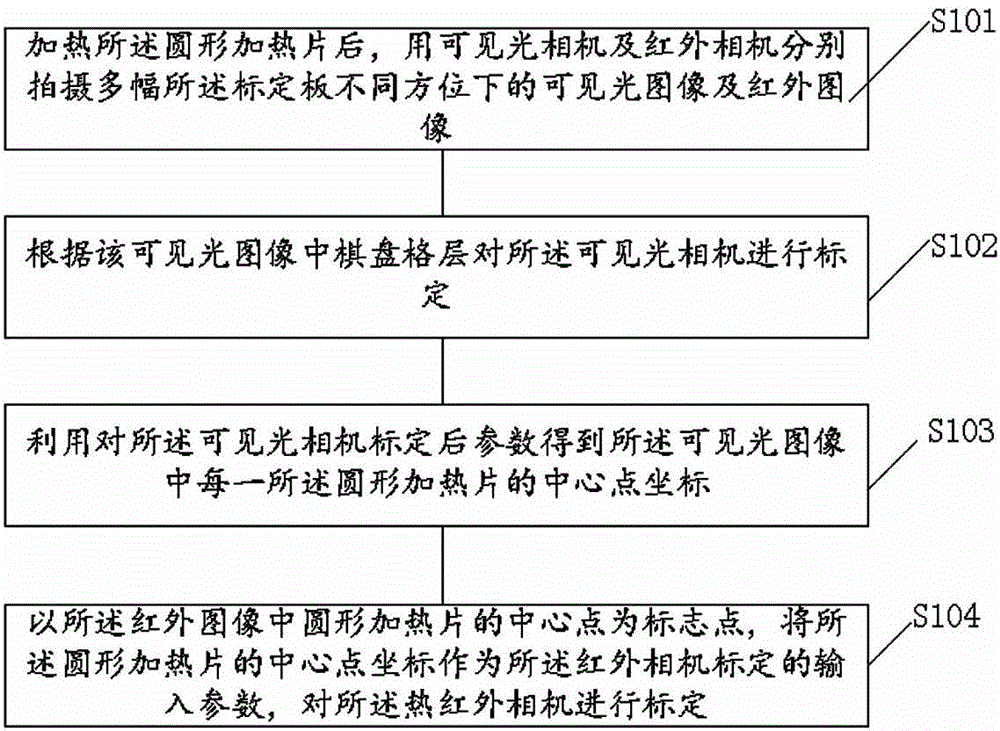

A calibration method and a calibration board technology, applied in image data processing, instruments, calculations, etc., can solve problems such as complex calibration procedures, lack of detailed information in images, and low resolution of thermal infrared cameras, and achieve simple calibration methods and structural Simple, easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

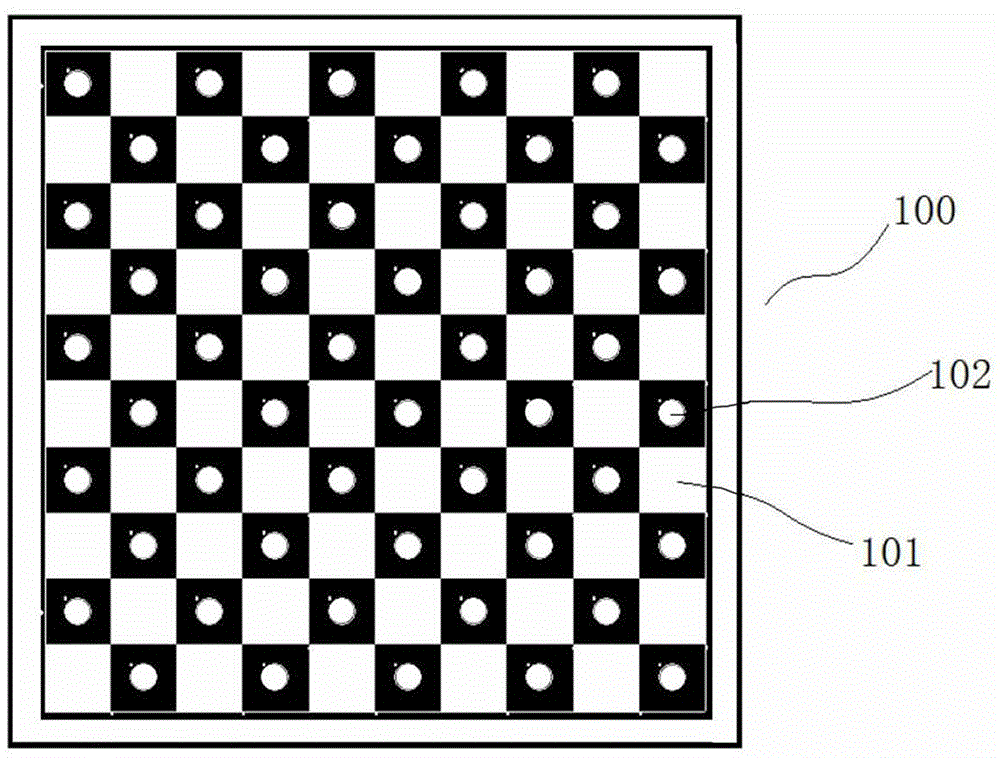

[0021] See figure 1 ,Should figure 1 The structure of the calibration board of the present invention is shown, the calibration board includes a square substrate 100, the substrate is provided with a checkerboard layer 101 for calibration of a visible light machine camera, and the checkerboard layer is located in front of the substrate On the surface, the checkerboard layer is a chessboard pattern layer formed by an array of black and white squares with the same size; wherein, a circular heating chip 102 for infrared camera calibration is installed on the front surface of each black square, The temperature of the circular heating sheet is controllable and connected to a temperature-controllable heating circuit; the center of the circular heating sheet coincides with the center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com