Air cooling radiator

A heat dissipation device and air-cooling technology, which is applied to cooling/heating devices of lighting devices, lighting devices, lighting and heating equipment, etc., can solve problems such as chip temperature rise and chip failure, and achieve simple fabrication and installation and easy production Good operation and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

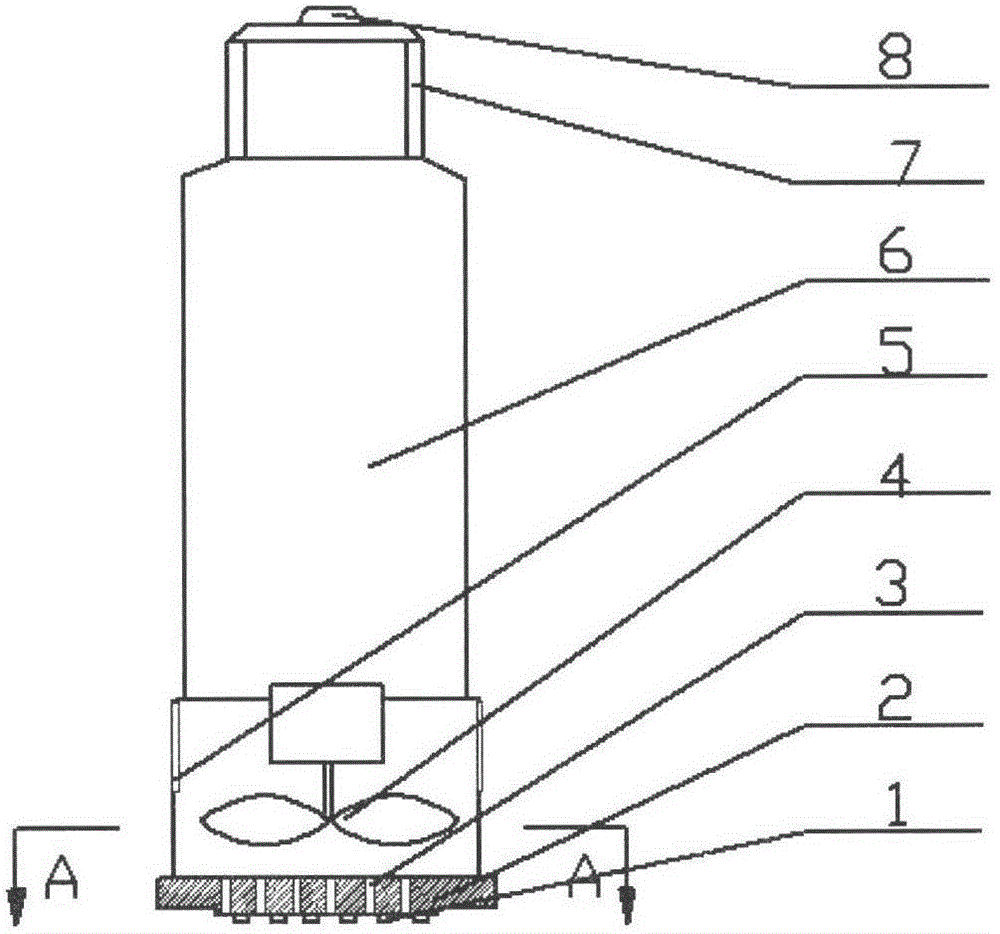

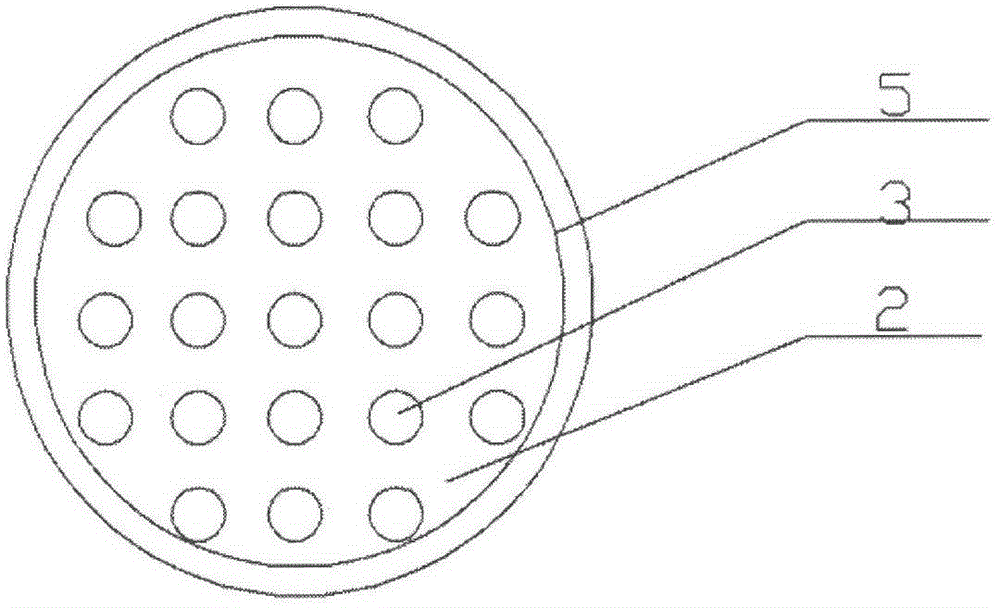

[0015] combine figure 1 and figure 2 The specific embodiment of the present invention is further described:

[0016] According to the technical solution provided by the present invention, an air-cooled heat dissipation device includes a chip 1, a heat dissipation base 2, a heat dissipation hole 3, a fan 4, a fan box 5, a lamp body 6, a screw port 7, and a lamp electrode tip 8. The chip 1 described above is closely attached to the heat dissipation base 2, the lamp body 6 is fixedly connected to the heat dissipation base 2 through the fan box 5, and a control circuit is installed in the lamp body 6, and the control circuit uses wires to communicate with the chip 1 and Fan 4 is connected.

[0017] The fan 4 is fixedly installed in the fan box 5, and the side of the fan box 5 is provided with ventilation slots.

[0018] The heat dissipation base 2 is provided with an axial heat dissipation hole 3, and the heat dissipation base 2 is made of copper or aluminum.

[0019] Working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com