A chemical slurry or dissolving slurry preparation method and its experimental displacement cooking device

A technology of displacement cooking and experiment, applied in the direction of digester, textiles, papermaking, papermaking, etc., can solve the problems of difficulty in realization and high cost, and achieve the effects of convenient use, reasonable structure and simple and easy technical means.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

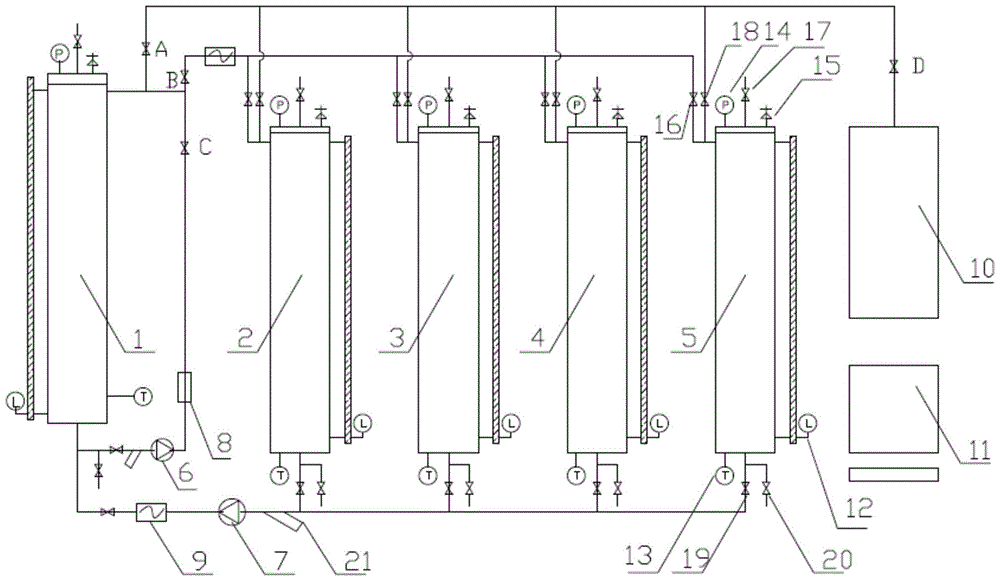

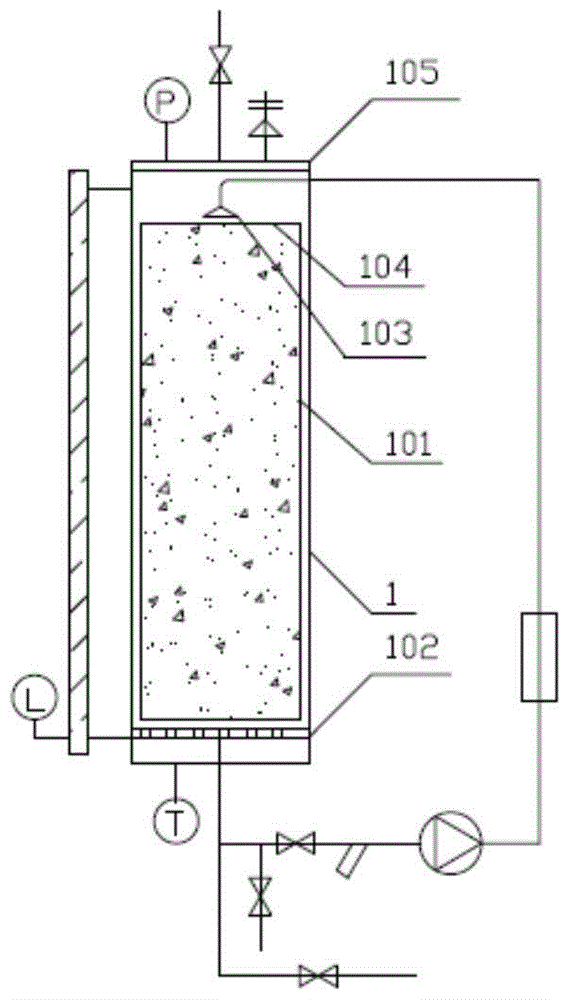

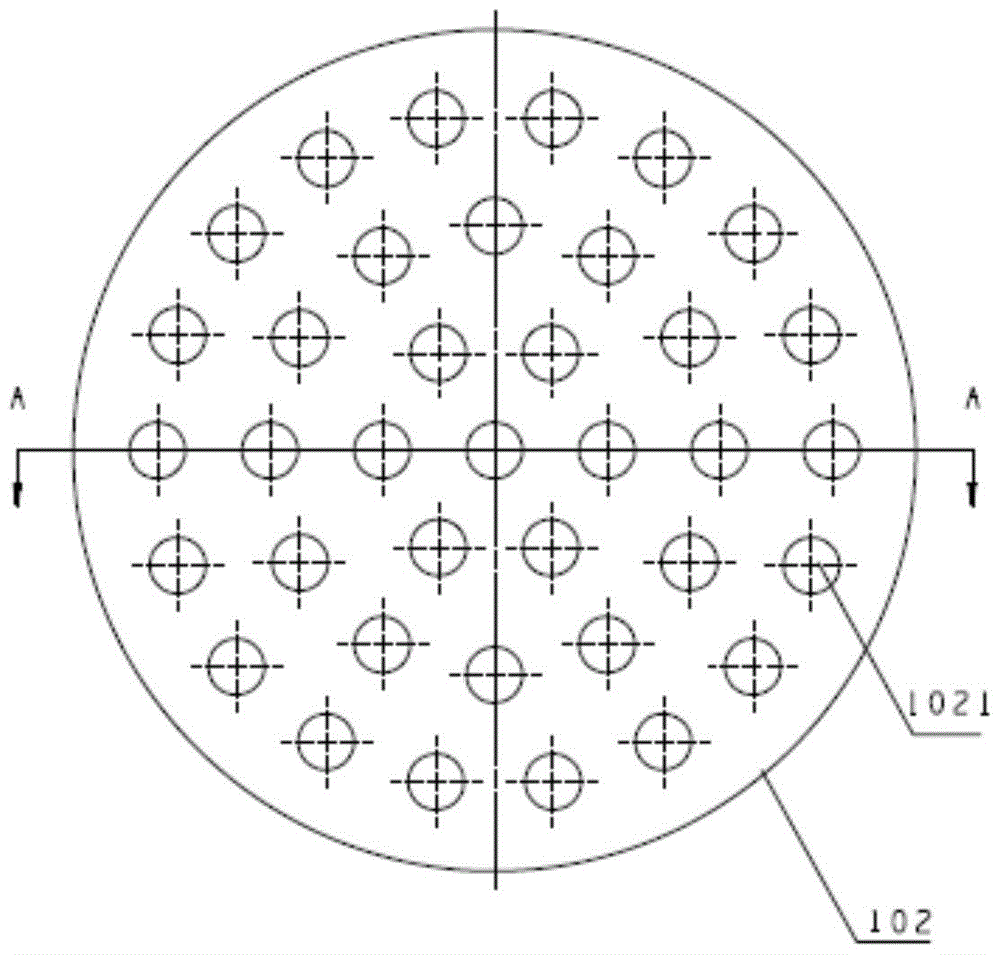

[0057] Such as figure 1 -6 shown. An experimental displacement cooking device of the present invention comprises a cooker 1, a hot white liquor tank 2, a hot black liquor tank 3, a warm black liquor tank 4, a washing liquid tank 5, a steam generator 10, and a DCS operating system 11;

[0058] The upper liquid port of the digester 1 is communicated with the steam generator 10 through the steam main pipe; the interface end of the steam main pipe and the upper liquid port of the digester 1 is provided with a valve A, and the interface end of the steam main pipe and the steam generator 10 is provided with a valve D ;

[0059] The respective liquid inlets of the hot white liquid tank 2, the hot black liquid tank 3, the warm black liquid tank 4, and the washing liquid tank 5 have two interfaces, one of which is connected to the liquid inlet main pipe through the liquid inlet valve 16, and the other interface is connected to the main liquid inlet through the liquid inlet valve 16. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com