Device and process for washing carpets

A technology of water washing device and water spraying device, which is applied in the field of carpet printing production, can solve the problems of high sewage treatment pressure, difficult carpet drying, low processing efficiency, etc., achieve low water consumption, facilitate daily maintenance, and high recycling rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

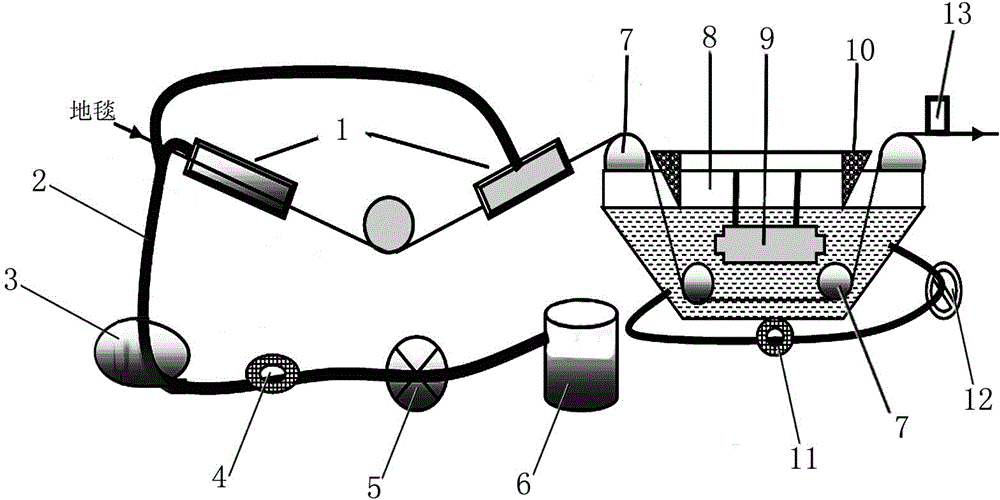

[0023] A carpet washing device includes a paste recovery device, a washing tank 8, a guide roller 7, a water spray device 10, a water flow flushing device 9 and a vacuum suction device 13. The paste recovery device includes two groups of suction cylinders 1, suction pipeline 2, vacuum pump 3, filter device 4, centrifugal dehydration device 5 and mixing bucket 6; 1.3m trapezoidal tank, water flow flushing device 9 and two guide rollers 7 are installed in the tank.

[0024] The suction cylinder 1 is connected to the inlet of the vacuum pump 3 through the suction pipe 2;

[0025] The water washing tank 8 is provided with an automatic water addition system control, mainly including a filter 11 and a circulation pump 12, through which the water level in the water washing tank is controlled by the automatic water addition system, and the water in the water tank is circulated and filtered through the circulation pump and filter to remove impurities .

[0026] The diameter of the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com