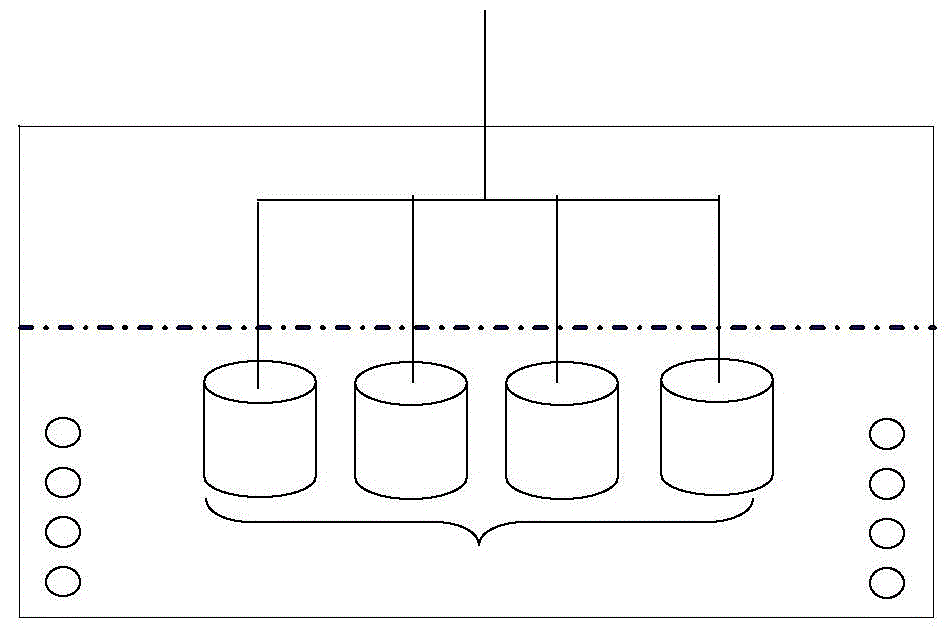

Micro-arc oxidation device for improving film thickness evenness and energy utilizing rate based on separate type compensation cathode

A technology of uniform thickness and micro-arc oxidation, applied in the field of material surface treatment based on solution discharge and micro-arc oxidation of workpiece surface, can solve the problems of uneven film thickness and low energy utilization rate, reduce reactive heat generation, The effect of reducing additional cooling power and reducing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0021] Embodiment 2. The difference between this embodiment and the micro-arc oxidation device based on the separate compensation cathode to improve the uniformity of film thickness and energy utilization described in Embodiment 1 is that the insulating frame 7 is processed with a plurality of bolts. Mounting holes.

[0022] In this embodiment, a plurality of bolt installation holes are processed on the insulating frame 7, so that the position of the anode rod 3 can be adjusted according to the actual oxidation needs of the workpiece.

specific Embodiment approach 3

[0023] Embodiment 3. The difference between this embodiment and the micro-arc oxidation device based on the separated compensation cathode to improve the uniformity of film thickness and energy utilization in Embodiment 1 is that the micro-arc groove 1, the upper cathode Frame 2, anode rod 3, workpiece hanging rod 4, compensation cathode hanging rod 5, compensation cathode plate 6 and anode clamp 8 are all realized by conductive materials.

specific Embodiment approach 4

[0024] Embodiment 4. The difference between this embodiment and the micro-arc oxidation device based on the separate compensation cathode to improve film thickness uniformity and energy utilization rate in Embodiment 3 is that the workpiece hanging rod 4 is connected to the upper cathode frame. 2. Insulating rubber is pasted on the parts where the through-holes of the bottom plate are in contact.

[0025] Because in the actual installation and use process, due to the factors of man-made or electrolyte flow, it is easy to contact between the workpiece hanging rod 4 and the through hole of the bottom plate of the upper cathode frame 2, so it is necessary to connect the workpiece hanging rod 4 to the upper cathode frame. 2. An insulator is coated on the part where the through hole of the bottom plate contacts, and is used for electrical isolation between the cathode and the anode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com