Method for removing microscopic nonmetallic inclusion in molten steel by using nitrogen-increasing nitrogen-precipitating process

A technology of non-metallic inclusions and inclusions, applied in the field of metallurgy, can solve problems such as the difficulty of forming small dispersed bubbles

Active Publication Date: 2015-03-11

UNIV OF SCI & TECH BEIJING

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The technical problem to be solved by the present invention is to provide a method for removing microscopic non-metallic inclusions in molten steel by

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

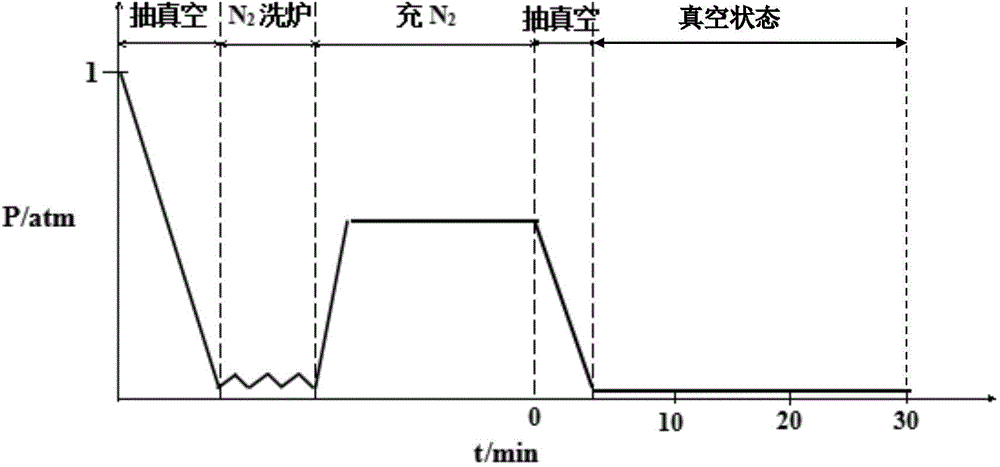

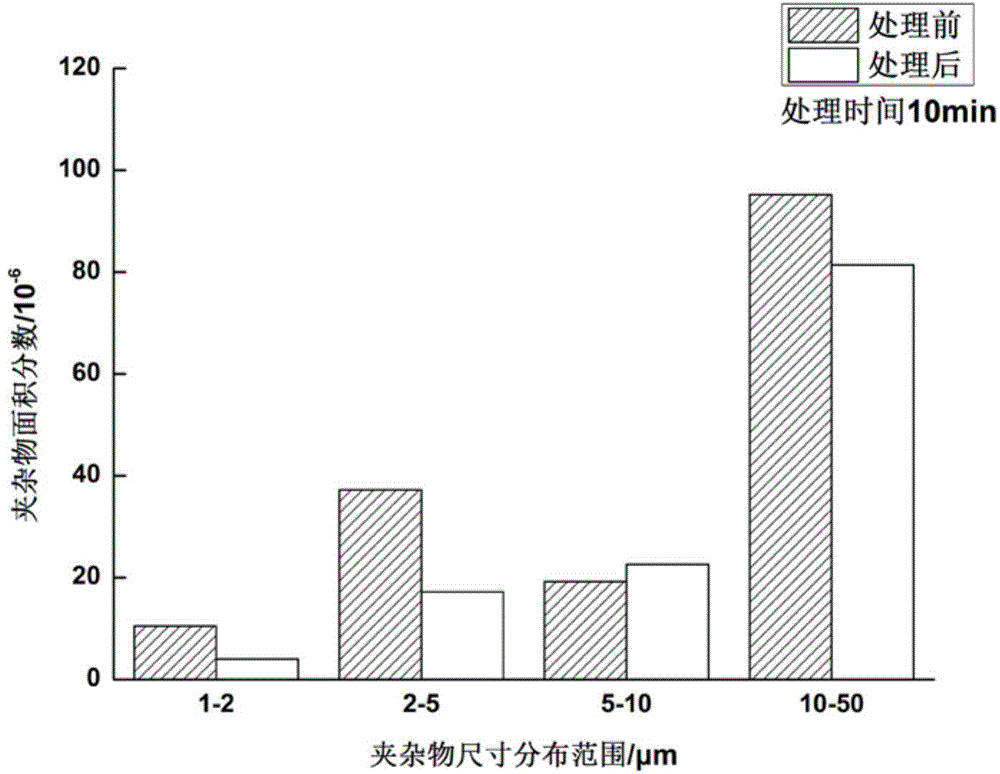

A provided method for removing microscopic nonmetallic inclusion in molten steel by using a nitrogen-increasing nitrogen-precipitating process comprises introducing a soluble gas N2 into molten steel, or enable molten steel to be at an environment with relatively high nitrogen partial pressure, so as to enable the nitrogen content in the molten steel to be substantially increased; under the vacuum condition, separating out nitrogen form molten steel, and enabling nitrogen to be separated from the surface of the microscopic nonmetallic inclusion in the molten steel and form bubbles by controlling the separation speed, so as to enable bubbles and the inclusions to float upwards together; and further capturing the microscopic inclusions in the steel in the bubble upward-floating process, and enabling the bubbles and the inclusions to float upwards together. Because the upward floating speed of bubbles is fast, the upward-floating removal speed of the inclusions in steel can be substantially improved. The nitrogen bubble generated by using the method is fine in dimension and is distributed in a dispersive way, and the inclusion removal effect is obvious.

Description

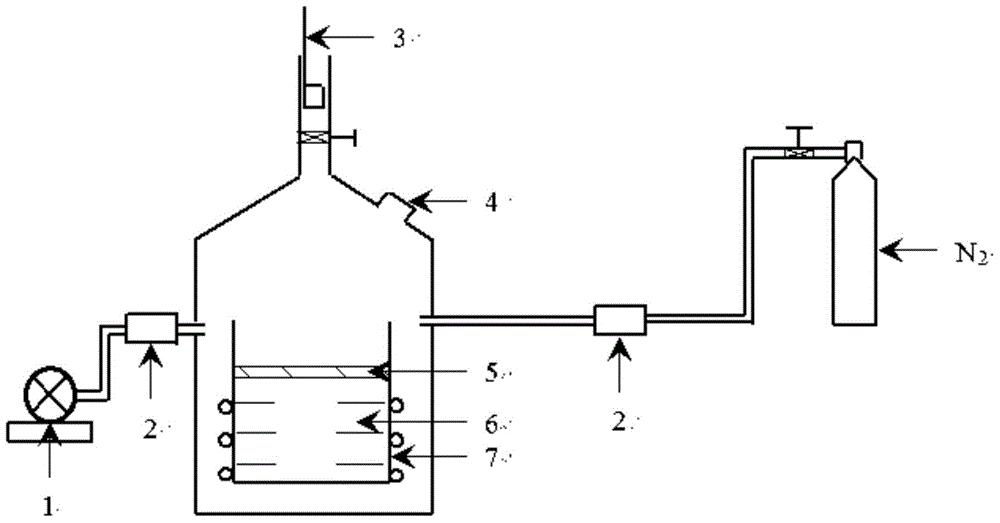

Technical field [0001] The invention belongs to the field of metallurgical technology, and relates to a technique for removing inclusions in molten steel, in particular to a method for removing microscopic non-metallic inclusions in molten steel by nitrogen-increasing and nitrogen evolution method, which can significantly promote microscopic inclusions in molten steel To improve the cleanliness of molten steel. Background technique [0002] Inclusions in steel often harm the performance of steel. Although metallurgical technology has progressed rapidly in recent years and the cleanliness of steel has improved rapidly, the control of inclusions in steel often cannot fully meet the requirements of high-quality steel, especially the size of steel. The control of small (≤10μm) microscopic inclusions has always been a difficulty in the production of some high-quality steels. [0003] A large number of studies have shown that blowing inert argon gas into the molten steel through the bot...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21C7/072C21C7/10

Inventor 刘建华李康伟

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com