Preparation method of heatproof anthocyanin pigment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

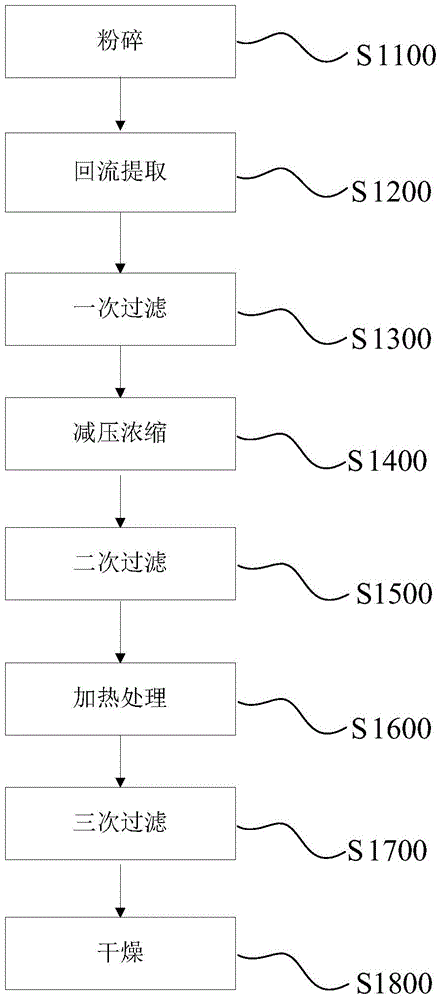

[0026] The invention provides a method for preparing heat-resistant anthocyanin pigments, figure 1 A schematic flow diagram of the preparation method of the present invention is shown. Such as figure 1 As shown, this includes the following steps:

[0027] Reflux extraction step S1200: reflux extracting the anthocyanin plant material with an acidic ethanol solution with a pH of 2.5-3.5 to obtain an extract;

[0028] Primary filtration step S1300: filtering the extract through a filter device with a filter aperture of 150-250 mesh and 5-15 μm in sequence to obtain a crude filtrate;

[0029] Concentrating under reduced pressure step S1400: concentrating the crude filtrate under reduced pressure at 40-60°C until the Baume degree is 2-4° to obtain a concentrate;

[0030] Secondary filtration step S1500: filtering the concentrated solution with an ultrafiltration membrane to obtain a refined filtrate;

[0031] Heat treatment step S1600: adding at least one of acetic acid, acetic...

Embodiment 1

[0042]1000 kg of red rice is used as raw material, washed and crushed to 20 mesh powder. Use 12,000 kg of acidic ethanol solution with pH 2.5 (hydrochloric acid and 40 vol% ethanol) to carry out reflux extraction on the above-mentioned pulverized red rice, and extract at 40°C for 60 minutes to obtain an extract. The extract was filtered sequentially through a 150-mesh filter sieve and a 15 μm filter bag to obtain 10,000 kg of crude filtrate. Concentrate under reduced pressure at 50°C to obtain 4000 kg of concentrated liquid. The obtained concentrated solution was filtered through a hollow fiber membrane with a filter pore size of 0.1 μm to obtain 3800 kg of refined filtrate. Add 4 kg of acetic anhydride and 2 kg of sodium phytate to the fine filtrate, stir evenly, place in a constant temperature water bath at 80°C and heat for 40 minutes, and then use a polyacrylamide membrane with a molecular weight cut-off of 500 to process the heated fine filtrate. filter, get The heat-...

Embodiment 2

[0044] Take 1000 kg of red radish as raw material, wash and crush it to 40 mesh powder, use 20000 kg of pH3.0 acidic ethanol solution (phosphoric acid and 15vol% ethanol to form) to carry out reflux extraction on the above-mentioned crushed red radish, at 50 ℃ Extract for 50 minutes to obtain the extract. The extract was successively filtered through a 200-mesh filter sieve and a 5 μm filter bag to obtain 20,000 kg of crude filtrate. Concentrate under reduced pressure at 40°C to obtain 14000 kg of concentrated liquid. The obtained concentrated solution was filtered through a hollow fiber membrane with a filter pore size of 0.2 μm to obtain 13,200 kg of refined filtrate. Add 1 kg of acetic acid and 3 kg of phytic acid to the fine filtrate, stir evenly, place in a constant temperature water bath at 80°C and heat for 30 minutes, then filter the heated fine filtrate with a polyacrylamide membrane with a molecular weight cut-off of 2000, have to The heat-resistant radish red pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com