Shot peening strengthening device for high-speed train wheel

A technology of shot peening and train wheels, which is applied in the field of metal surface strengthening, can solve the problems of strengthening the contact surface between wheel sets and rails, and achieve the effects of high equipment efficiency, time saving and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

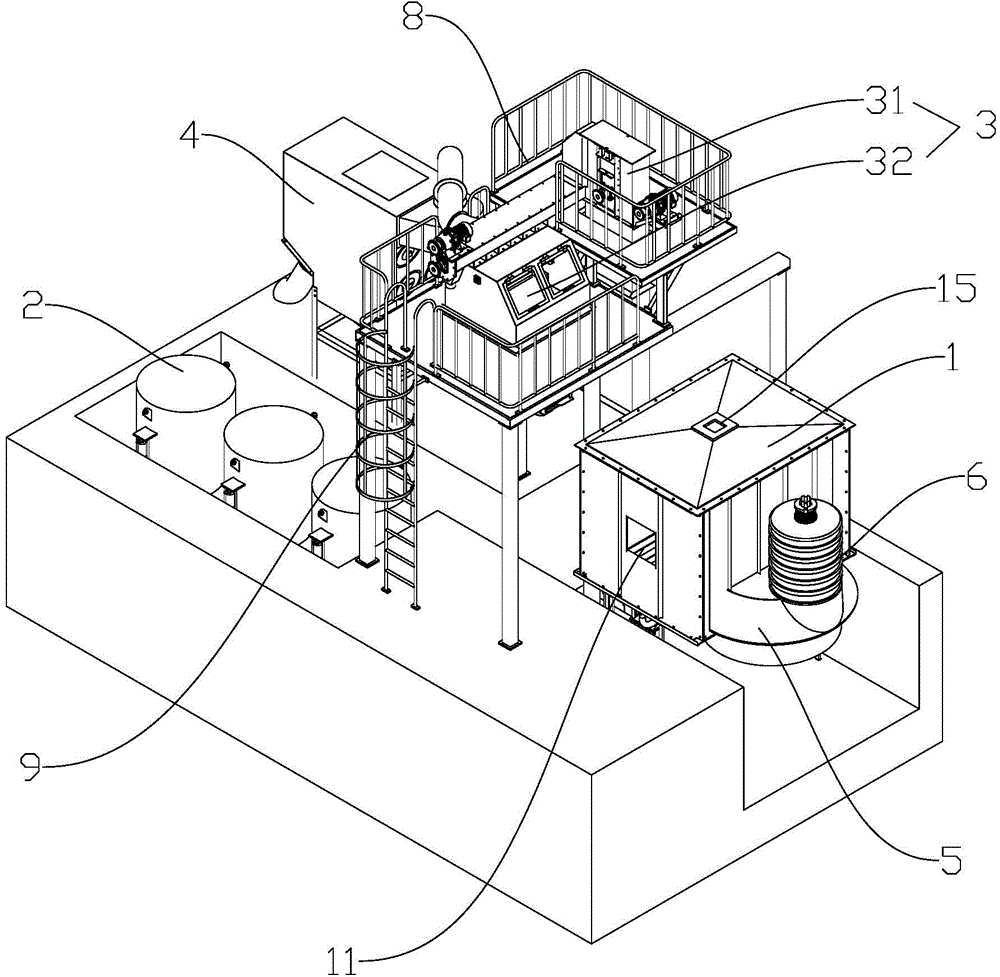

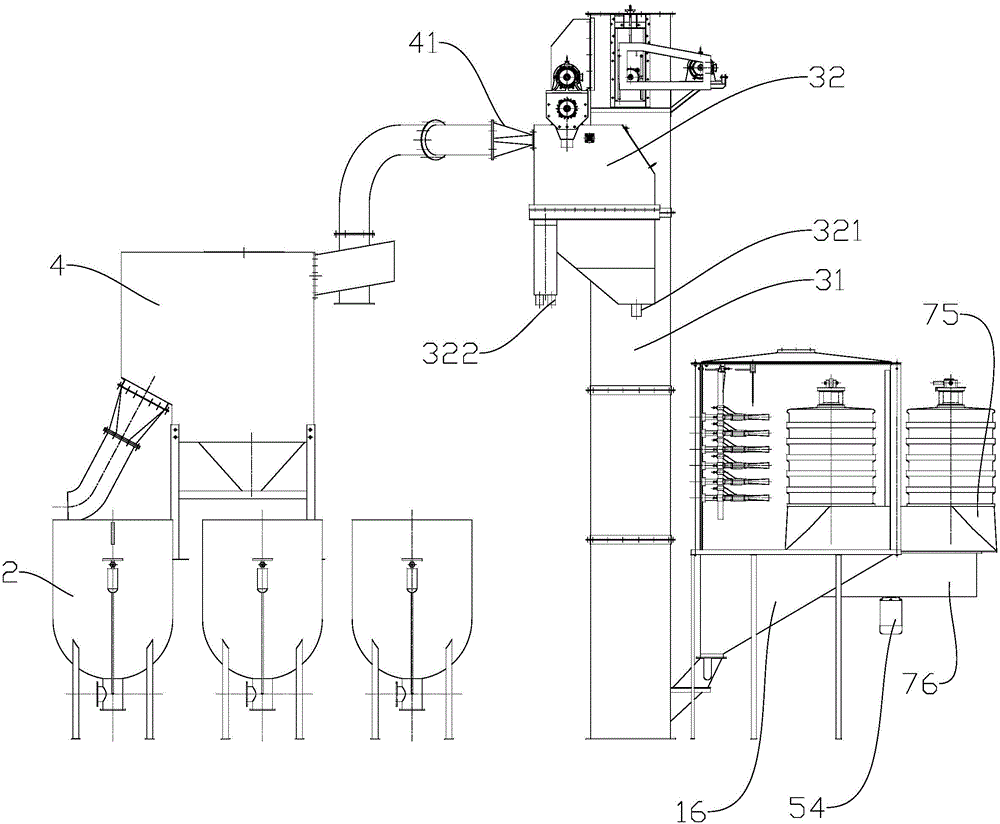

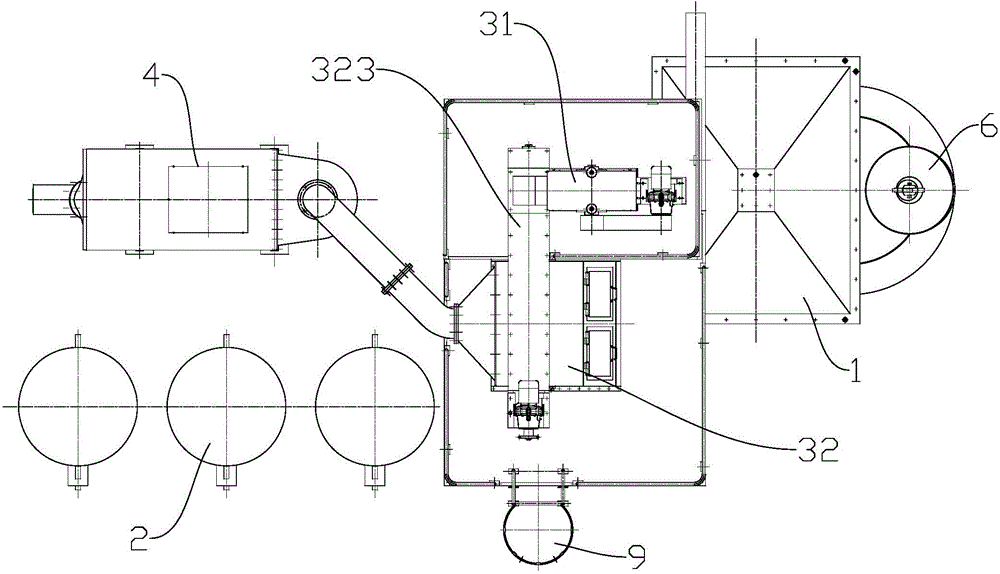

[0037] Such as Figure 1-8 As shown, this embodiment discloses a rotary double-station high-speed train wheel shot peening machine, including a shot blasting chamber 1, a shot blaster 2, a shot separation and recovery device 3, a dust removal device 4, a rotary table 5 and a fixture Workbench6. One side of the shot blasting chamber 1 is provided with an observation port 11, so that the shot peening effect can be understood in time without stopping the vehicle during the shot peening process. A workpiece inlet is provided on a side adjacent to the viewing port 11 .

[0038] The rotary table 5 includes a power shaft 51 and a bearing seat 52, the power shaft 51 is installed on the bearing seat 52, and the bearing seat 52 is fixed on the foundation with anchor bolts 53, and there is a certain gap with the foundation. The motor 54 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com