Method utilizing ultrasonic technology to regenerate used sodium silicate sand

A kind of water glass sand and ultrasonic technology, which is applied in the cleaning/processing machinery of casting materials, casting molding equipment, metal processing equipment, etc., can solve the problem of high water consumption, difficulty in wet regeneration, low regeneration rate problem, to achieve excellent casting effect and the effect of reducing regeneration cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

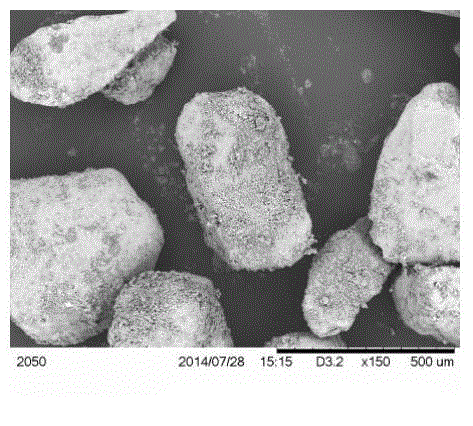

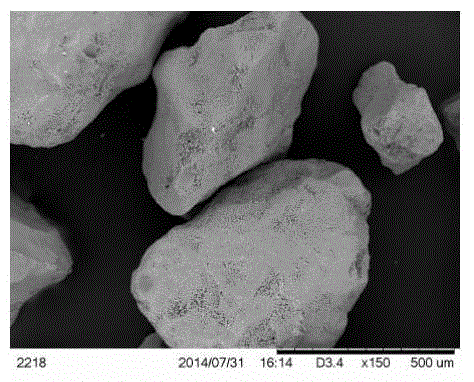

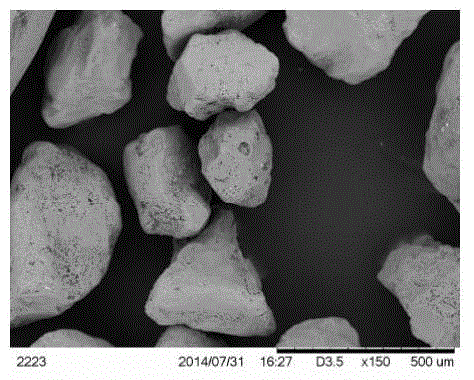

Image

Examples

Embodiment 1

[0033] (1) Prepare a sodium hydroxide solution with a mass concentration of 15%.

[0034] (2) According to the volume ratio of the used sodium silicate sand to the sodium hydroxide solution at 1:1, put the used sodium silicate sand into the prepared sodium hydroxide solution for immersion, soak at room temperature for 16 hours, and separate the sodium silicate sand after the immersion is completed , NaOH with a mass of 3% of the mass of the lye is added to the lye for recycling.

[0035] (3) Place the old sodium silicate sand immersed in step (2) in clean water, and use ultrasonic ultrasound with a frequency of 25 kHz for 25 minutes, and the mass ratio of the old sodium silicate sand to water is 1:2.

[0036] (4) The water glass sand after ultrasonic in step (3) is filtered and separated from the waste liquid, and the water glass sand is washed and then dried to obtain stripped reclaimed sand. The washing wastewater is filtered to obtain waste residue and washing water. The waste re...

Embodiment 2

[0039] (1) Prepare a sodium hydroxide solution with a mass concentration of 5%.

[0040] (2) According to the volume ratio of the used sodium silicate sand and the sodium hydroxide solution as 1:2, put the used sodium silicate sand into the prepared sodium hydroxide solution and soak for 36h at room temperature. After the immersion is completed, the sodium hydroxide solution will be separated. , NaOH with a mass of 1% of the mass of the lye is added to the lye for recycling.

[0041] (3) Place the old sodium silicate sand immersed in step (2) in a NaOH solution with a mass concentration of 20%, use ultrasonic ultrasound with a frequency of 50 kHz for 48 minutes, and the mass ratio of the old sodium silicate sand to water is 1:5.

[0042] (4) The water glass sand after ultrasonic in step (3) is filtered and separated from the waste liquid, and the water glass sand is washed and dried to obtain the stripped regenerated sand. The washing wastewater is filtered to obtain waste residue a...

Embodiment 3

[0045] (1) Prepare a sodium hydroxide solution with a mass concentration of 20%.

[0046] (2) According to the volume ratio of the used sodium silicate sand to the sodium hydroxide solution of 1:1.2, put the used sodium silicate sand into the prepared sodium hydroxide solution and soak for 24 hours at room temperature. After the immersion is completed, separate the sodium silicate sand , NaOH with a mass of 4% of the mass of the lye is added to the lye for recycling.

[0047] (3) Place the old water glass sand immersed in step (2) in clean water, and use ultrasonic ultrasound with a frequency of 150 kHz for 5 minutes, and the mass ratio of the old water glass sand to water is 1:1.

[0048] (4) The water glass sand after ultrasonic in step (3) is filtered and separated from the waste liquid, and the water glass sand is washed and then dried to obtain stripped reclaimed sand. The washing wastewater is filtered to obtain waste residue and washing water. The waste residue is subjected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com