Inner transverse bar extrusion die for cylindrical component

A technology for extrusion dies and cylindrical parts, which is applied to the extrusion forming method of inner transverse ribs and the field of extrusion dies, and can solve the problems of unable to extrude inner ribs and unable to meet performance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

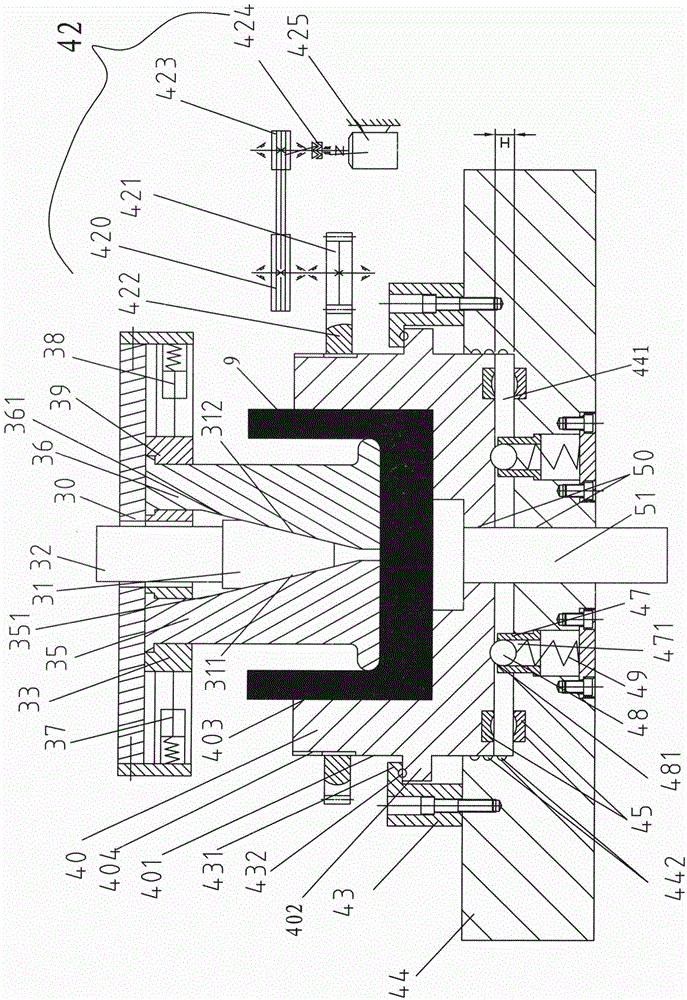

[0032] Such as Figure 5 As shown, an extrusion die for inner transverse ribs of cylindrical parts includes an upper die base 30, a double-acting press piercing cylinder joint 32, a wedge 31, a left punch 35, a right punch 36, and a left punch fixing plate 33 , the right punch fixed plate 39, the hydraulic cylinder 37 of the left push-pull fixed plate, the hydraulic cylinder 38 of the right push-pull fixed plate, the die 40, the limiter 43, the lower mold base 44, the thrust bearing plate 45, the steel ball bearing frame 47 , steel ball 48, spring 49, rotating device 42, left punch 35, right punch 36 are installed on the upper mold base 30 by left punch fixed plate 33, right punch fixed plate 39 respectively, left punch fixed plate 33, The right punch fixed plate 39 can slide left and right on the upper die base 30, one end of the hydraulic cylinder 37 of the left push-pull fixed plate is fixed on the upper die base 30, the other end is fixed on the left punch fixed plate 33, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com