Flue dirt removing device and flue dirt removing method

A flue and scale cleaning technology, used in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of time-consuming and laborious, poor cleaning effect, etc., to reduce environmental pollution, achieve remarkable scale cleaning effect, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

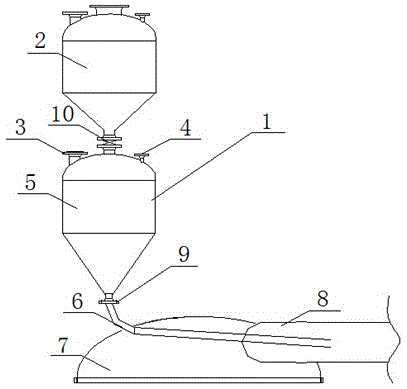

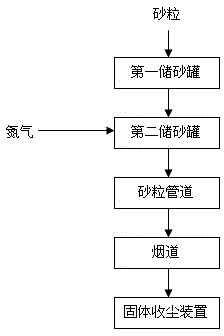

[0024] like figure 1 A flue descaling device is shown, which is composed of a sand storage device 1 and a sand pipeline 6, the sand storage device 1 is connected to the nitrogen delivery pipeline 3, and the outlet end of the sand storage device 1 is connected to one end of the sand pipeline 6 through a controlled The valve 9 is connected, and the other end of the sand pipe 6 is connected with the flue 8 arranged on the top of the chlorination furnace 7 furnace bodies.

[0025] The sand storage device 1 includes a first sand storage tank 2 and a second sand storage tank 5. A connection valve 10 is provided between the outlet end of the first sand storage tank 2 and the inlet end of the second sand storage tank 5. The connection valve 10 is Ball valve, the top of the second sand storage tank 5 is connected with one end of the nitrogen delivery pipeline 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com