Smoke washing device with scaling-shaped hole plate

A technology of washing device and gradually shrinking orifice plate, which is applied in the direction of combination device, dispersed particle separation, chemical instruments and methods, etc., can solve the problem that the slurry cannot fully absorb the pollution components, the desulfurization, denitrification and dust removal, and the gas disturbance is not strong enough. and other problems, to achieve the effect of increasing the flow rate, strengthening the collision and mixing of gas and liquid, and increasing the disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

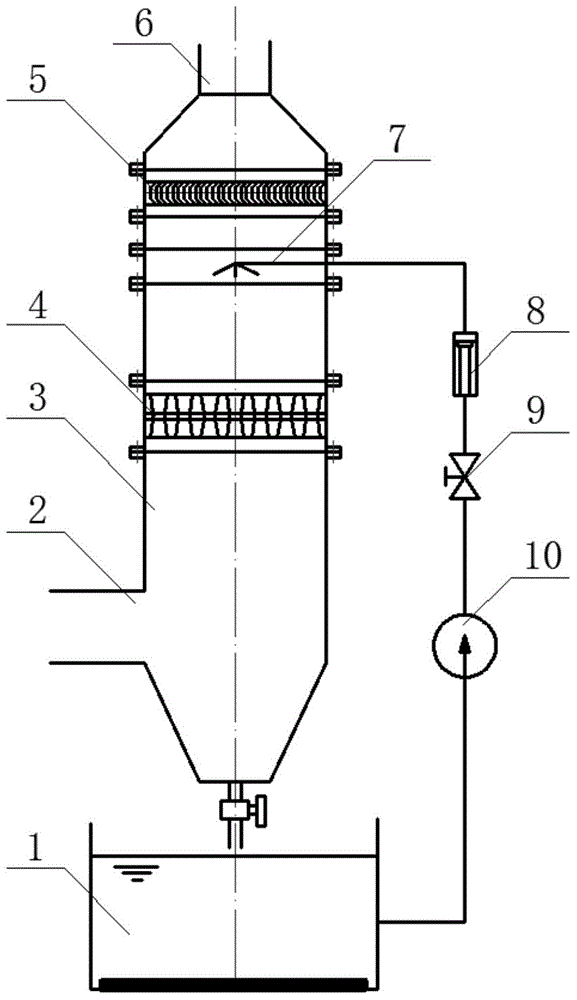

[0035] Such as figure 1 As shown, the present invention has a flue gas scrubbing device with a zoom-shaped orifice, including a tower body 3, a circulating liquid storage tank 1 arranged below the tower body 3, and the inside of the tower body 3 is sequentially arranged from bottom to top Zoom-shaped orifice plate 4, spray layer 7 and demister 5, flue gas inlet 2 is arranged at the bottom of tower body 3, and absorption tower outlet 6 is arranged at the top, the spray layer of the circulating liquid storage tank 1 and tower body 3 A slurry circulation pump 10, a flow control valve 9 and a flow meter 8 are sequentially arranged on the pipelines connected between the 7;

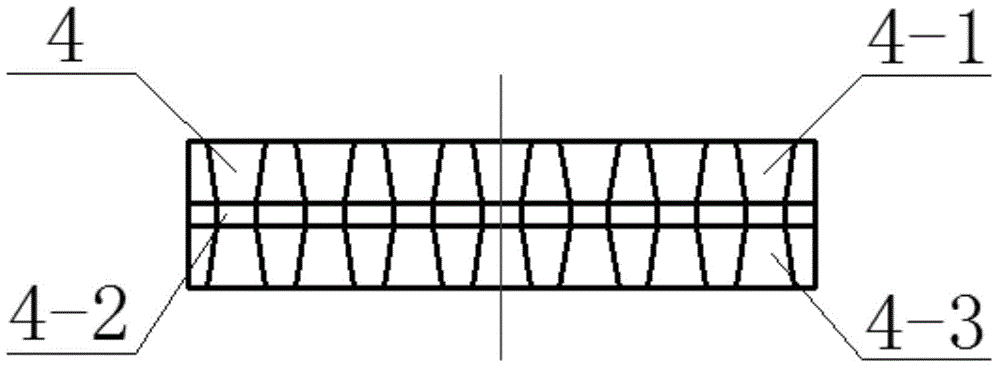

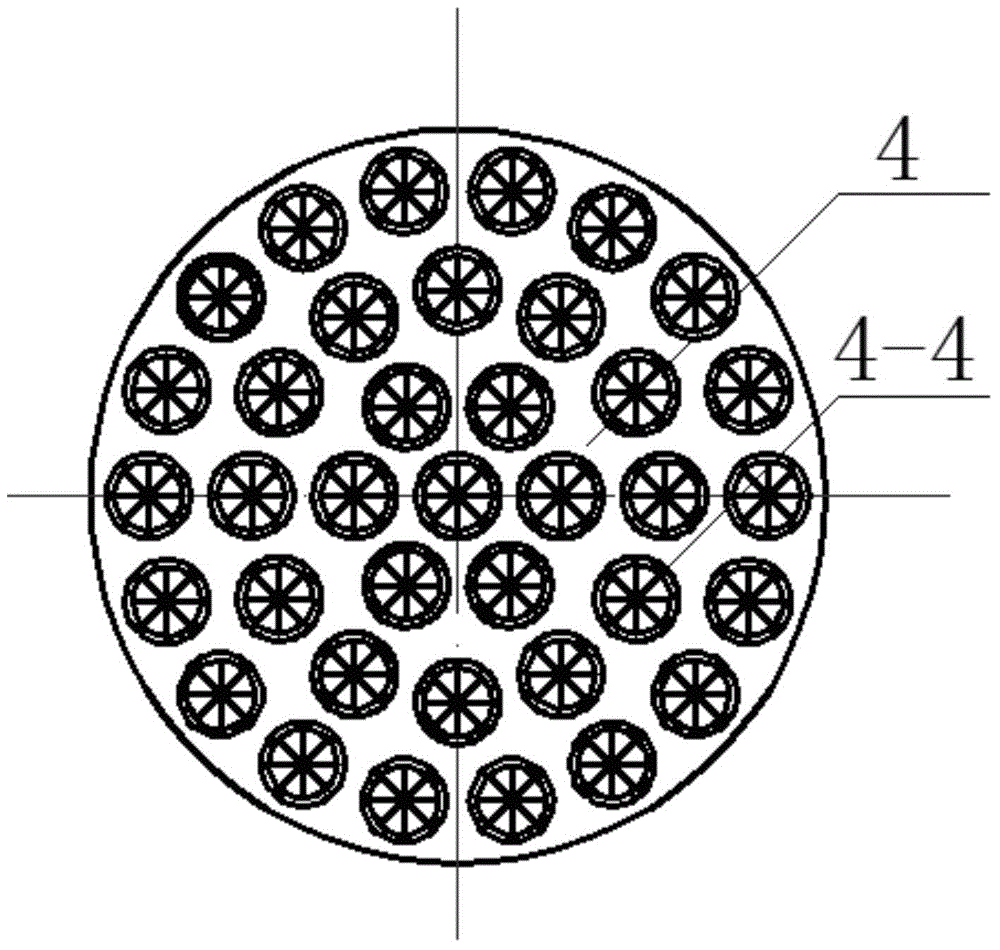

[0036] Such as Figure 2a and Figure 2b As shown, the zoom-shaped orifice 4 is composed of a tapered orifice 4-1, a cylindrical porous plate 4-2 and a gradually ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com