Disposable sterile syringe comprising protection sleeve tube

A technology of syringes and sheath tubes, applied in the field of medical equipment, can solve problems such as accidental needle stick injuries, needle contamination, incomplete excitation, etc., and achieve the effects of avoiding cross infection, good biodegradability, and avoiding needle stick injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

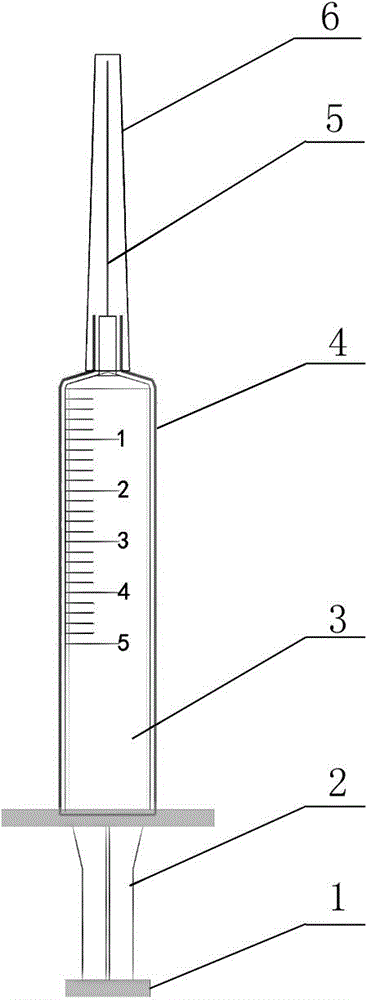

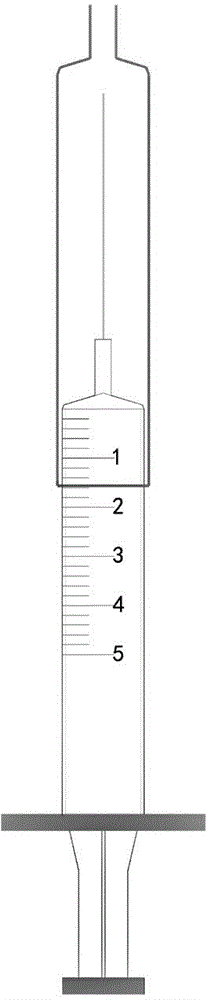

[0027] A disposable sterile syringe containing a protective sleeve, which includes a handle 1, a push rod 2, a syringe 3, a protective sleeve 4, a needle 5 and a trocar cap 6; the needle 5 is integrated with the syringe 3 and cannot be separated. This can avoid needle stick injuries caused during the process of separating the needle; the outer sleeve 4 is located outside the syringe 3; when the liquid is sucked, the needle cap does not need to be returned to protect the needle, but the outer sleeve is pushed toward the needle , Push it until it can cover the entire needle. After the nurse prepares the patient’s position and skin disinfection, perform the injection. At this time, you only need to push the outer tube in the opposite direction until the needle is completely exposed. This is good for protection The needle is in a sterile state before the injection, which helps to prevent the nurse from directly touching the needle during the process of returning the needle cap to ca...

Embodiment 2

[0030] An outer casing, which is prepared from the following parts by weight of raw materials: 20 parts of polybutylene succinate, 15 parts of polyvinyl alcohol, 8 parts of hydroxymethyl cellulose, 7 parts of polyglycolic acid, and chitosan 6 parts, 4 parts of polylactic acid, 3 parts of barium stearate, 2 parts of mica powder, 2 parts of corn starch, 1 part of sodium succinate and 1 part of silica gel. The pore volume of the silica gel is 0.60—0.85ml / g, on average The pore diameter is 4.5-7.0nm, the specific surface is 450-650m 2 / g; The particle sizes of the hydroxymethyl cellulose, chitosan, barium stearate, mica powder, corn starch and sodium succinate are all controlled at 100 mesh.

[0031] The preparation method of the above-mentioned outer sleeve includes the following steps: weigh each raw material in parts by weight for use; first, add each raw material into the agitator one by one, centrifuge at 1000 rpm for 3 minutes, and then stand for 12 hours to obtain a mixture; T...

Embodiment 3

[0034] An outer casing, which is prepared from the following parts by weight of raw materials: 22 parts of polybutylene succinate, 16 parts of polyvinyl alcohol, 10 parts of hydroxymethyl cellulose, 8 parts of polyglycolic acid, and chitosan 7 parts, 5 parts of polylactic acid, 4 parts of barium stearate, 3 parts of mica powder, 3 parts of corn starch, 2 parts of sodium succinate and 2 parts of silica gel. The pore volume of the silica gel is 0.60—0.85ml / g, on average The pore diameter is 4.5-7.0nm, the specific surface is 450-650m 2 / g; The particle size of the hydroxymethyl cellulose, chitosan, barium stearate, mica powder, corn starch and sodium succinate are all controlled at 150 mesh.

[0035] The preparation method of the above-mentioned outer sleeve includes the following steps: weigh each raw material in parts by weight for use; first, add each raw material into the agitator one by one, centrifuge at 1000 rpm for 3 minutes, and then stand for 12 hours to obtain a mixture; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com