Processing method for jasmine fragrant rice

A processing method, the technology of jasmine, is applied in food science, food ingredients as odor improvers, animal feed, etc. It can solve unreported problems and achieve the effects of strong market competitiveness, rich nutrition, great social benefits and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

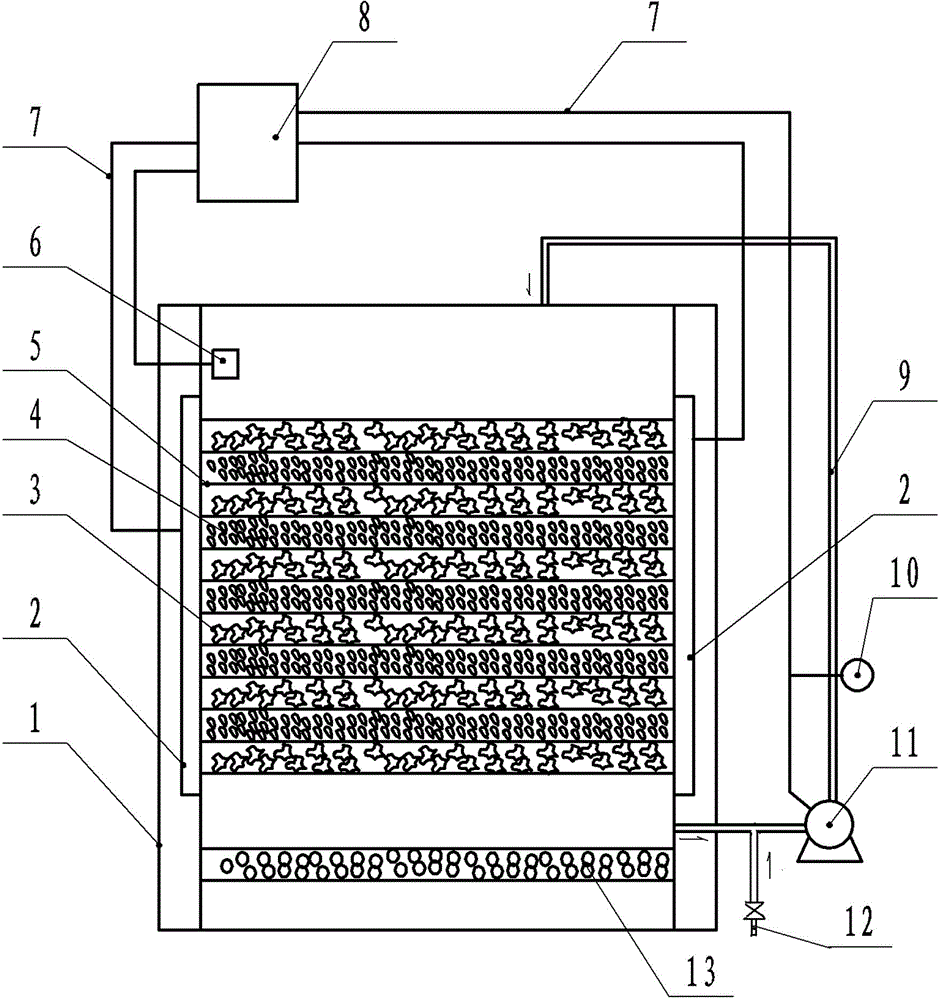

Image

Examples

Embodiment 1

[0032] The processing method of jasmine fragrant rice includes rice pretreatment, jasmine picking and maintenance, using jasmine to scent rice, and a process of recovering part of jasmine fragrance oil and scenting residue treatment during the process of using jasmine to scent rice.

[0033] The pretreatment of the rice is as follows: (1) paddy screening: select clean organic paddy, use drum primary cleaning sieve and vibrating screen to preliminarily clean the paddy, remove weeds, branches and leaves in the paddy; (2) remove Stone: Use a destoner to remove soil, sand and gravel mixed in the rice; (3) Magnetic separation: Use a magnetic separator to remove iron-containing impurities mixed in the rice; (4) Dry: Use a six-layer circulation dryer for agricultural products to dry Drying of paddy until the moisture content is 10%; (5) Hulling of paddy: using a rigid-flexible mill to dehull rice with a moisture content of 10%, and the husking rate is > 85%; (6) Grading of white rice:...

Embodiment 2

[0041] The processing method of jasmine fragrant rice includes rice pretreatment, jasmine picking and maintenance, using jasmine to scent rice, and a process of recovering part of jasmine fragrance oil and scenting residue treatment during the process of using jasmine to scent rice.

[0042] The pretreatment of the rice is as follows: (1) paddy screening: select clean organic paddy, use drum primary cleaning sieve and vibrating screen to preliminarily clean the paddy, remove weeds, branches and leaves in the paddy; (2) remove Stone: Use a destoner to remove soil, sand and gravel mixed in the rice; (3) Magnetic separation: Use a magnetic separator to remove iron-containing impurities mixed in the rice; (4) Dry: Use a six-layer circulation dryer for agricultural products to dry Drying of paddy until the moisture content is 15%; (5) Hulling of paddy: using a rigid-flexible mill to dehull rice with a moisture content of 15%, and the husking rate is > 85%; (6) Grading of white rice:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com