An electromechanical dual-purpose green grass braiding forming device

A forming device and dual-purpose technology, applied in the field of grass braid forming device, can solve the problems of low manual efficiency, irregular grass braids, etc., and achieve the effects of improving efficiency, low power consumption, and reducing pasture mildew.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

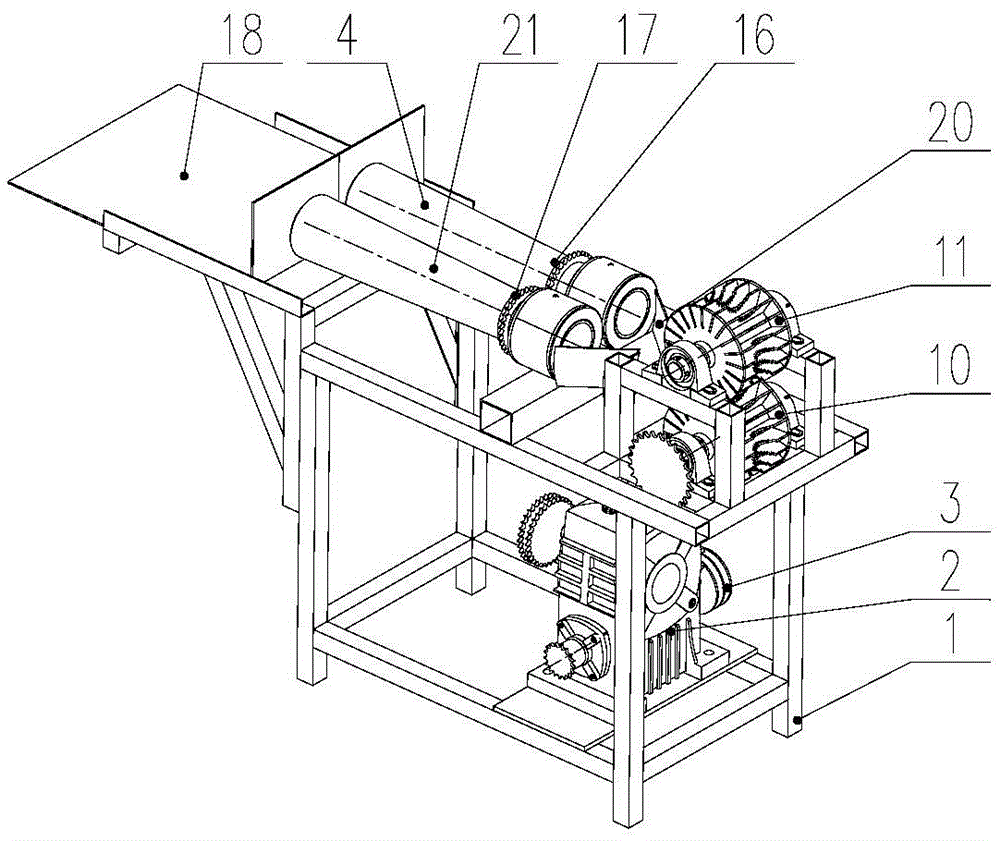

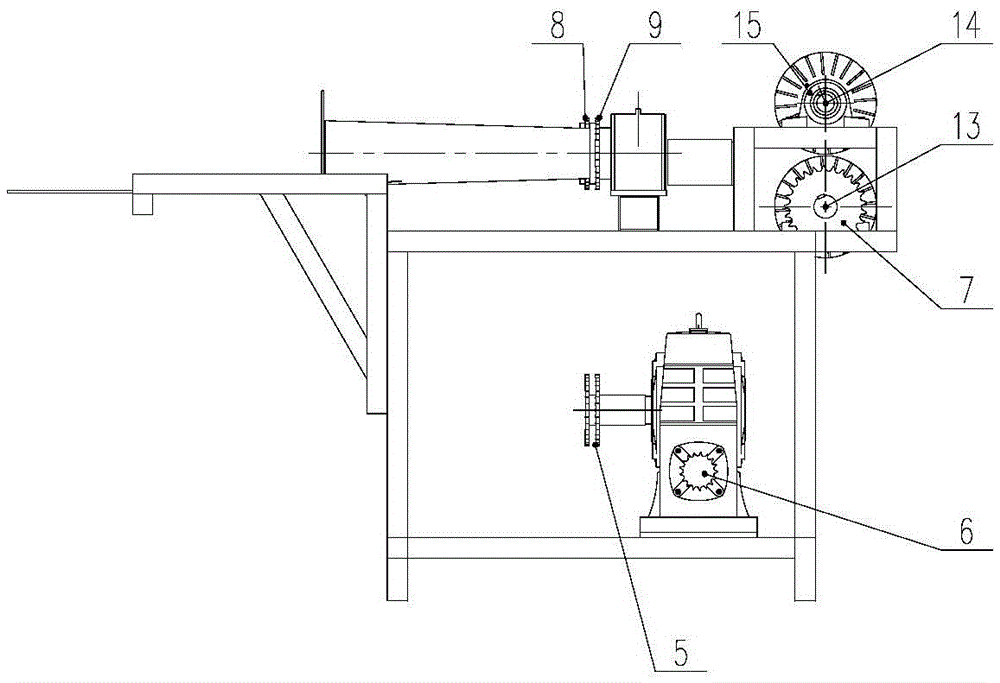

[0041] like figure 1 , 2 As shown, the electromechanical grass braiding forming device of the present invention includes a left forming drum 4 , a right forming drum 21 , a traction grass roller 10 and a driven grass roller 11 .

[0042] The molding device also includes a frame 1 , a gearbox 2 , a left sprocket rim 8 , a right sprocket rim 9 , a feeding pallet 18 and a guide plate 20 .

[0043] The structural forms and external dimensions of the left molding drum 4 and the right molding drum 21 are the same.

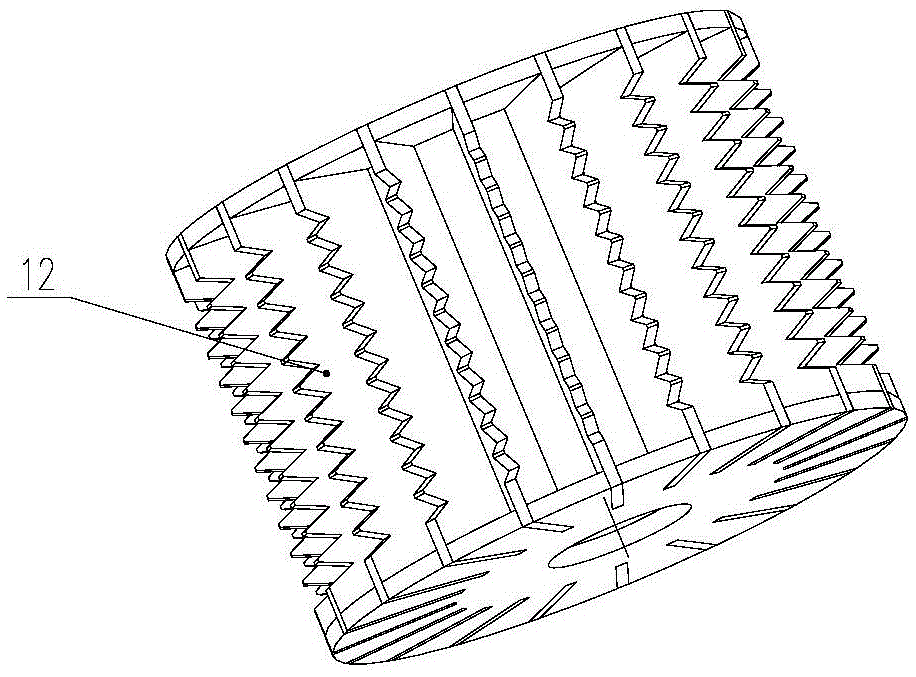

[0044] like Figure 4 As shown, the left molding drum 4 and the right molding drum 21 are cone drums with large feed end and small discharge end, and a pair of lifting plates 19 are installed inside.

[0045] The left forming drum 4 is fixedly connected to the left sprocket ring 8 through the left flange 16 ; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com